Connector

A technology of connectors and receiving parts, applied in the direction of connection, components of connection devices, devices for preventing wrong connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

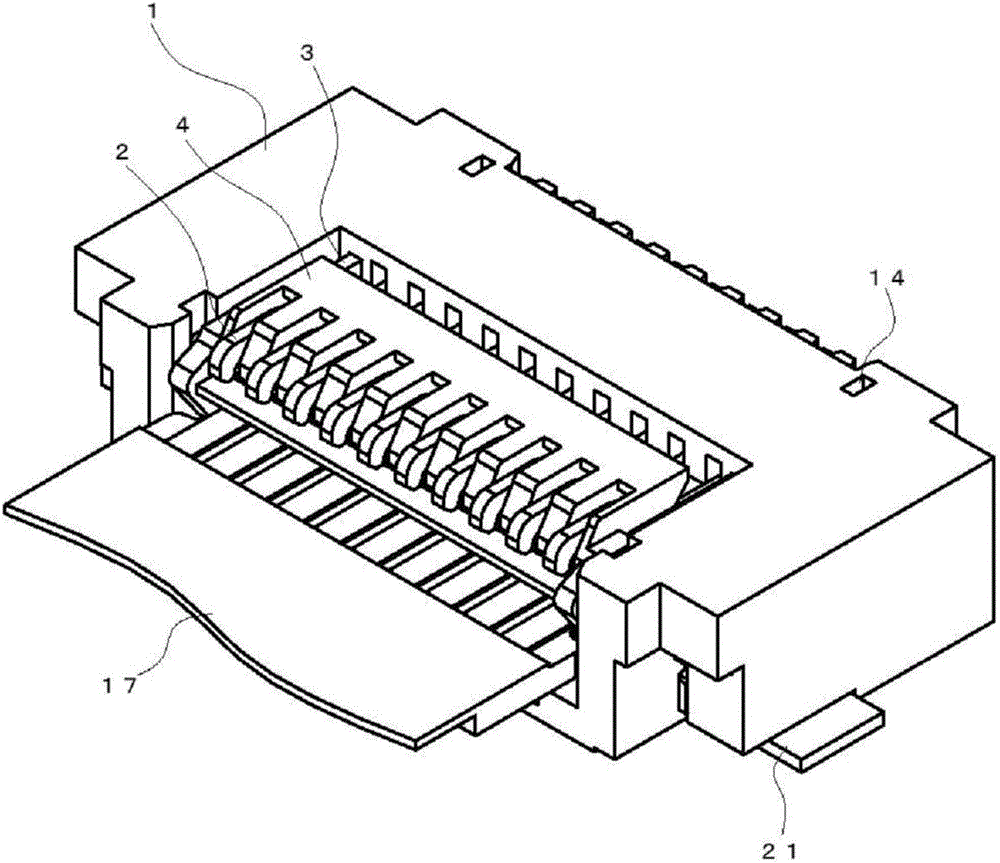

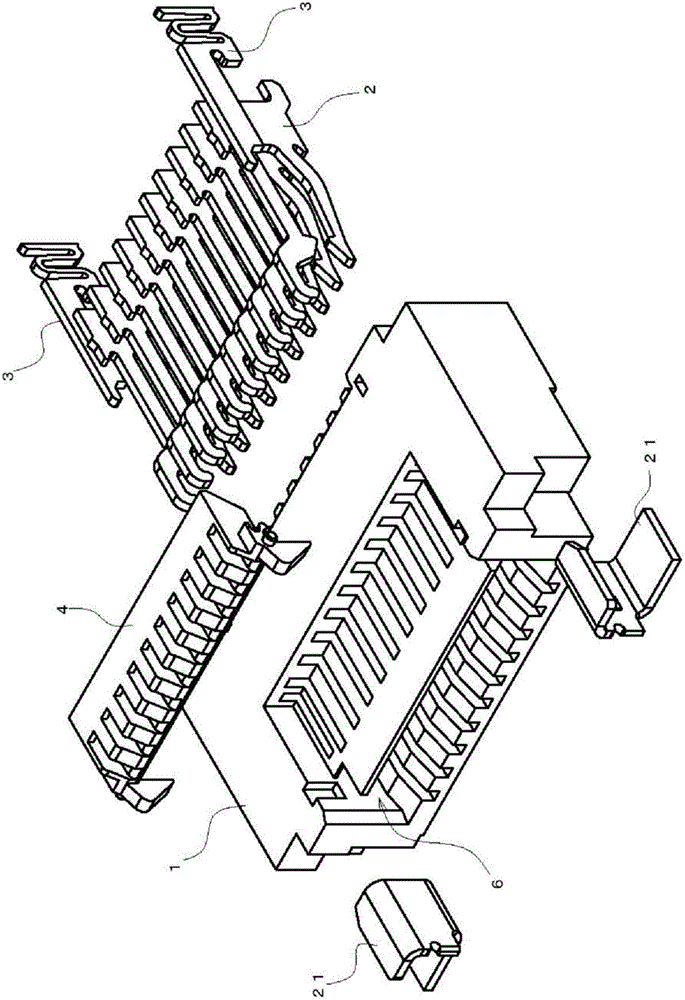

[0058] figure 1 is an overall view illustrating the connector according to the first embodiment, figure 2 is a perspective exploded view illustrating the connector. The connector is constituted by mounting the contact member 2 , the latch member 3 and the moving member 4 to the housing 1 .

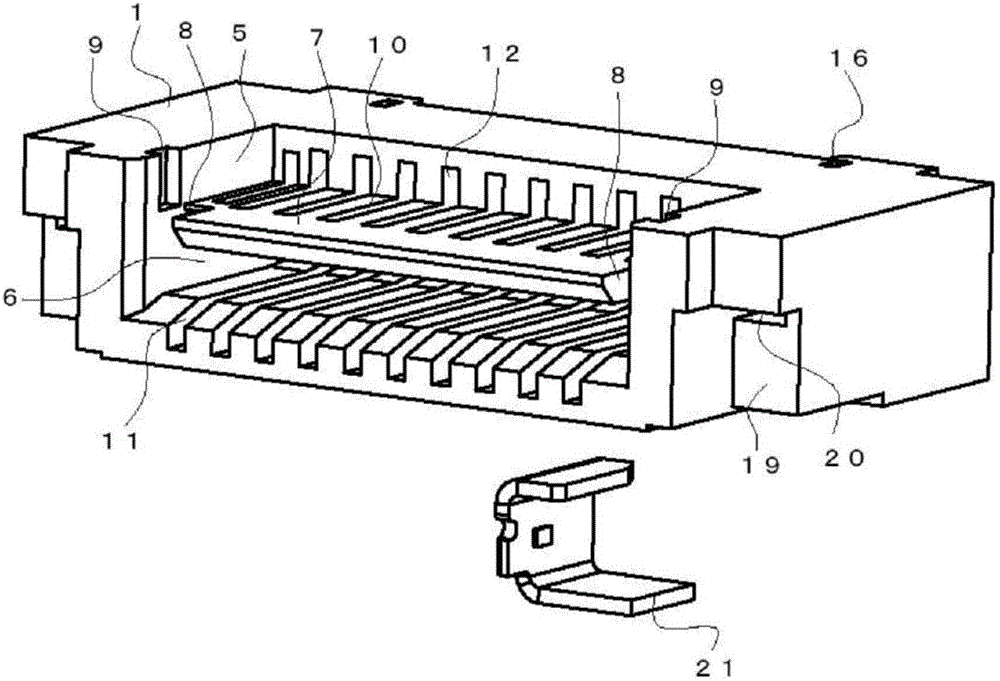

[0059] like Figure 3A and 3B As shown in , the case 1 is a product made by molding an electrically insulating resin material into a shape of parallel pipes approximately in a rectangular parallelepiped. A recess 5 and an insertion recess 6 are formed in the housing 1 . The recess 5 is open in the direction of the upper surface and the front surface. The insertion recess 6 is provided below the recess 5 and is open in the direction of the front surface. The recess 5 and the insertion recess 6 are separated by a partition wall 7 . Compared with the position of the front surface of the housing 1 , the front end portion of the partition wall 7 is located on the rear side, and the cuto...

no. 2 example )

[0079] Figure 13 A connector according to a second embodiment is illustrated. Since this connector differs from the connector of the first embodiment only in a part of the structure of the moving member 4, but is almost identical in other structures, the description of the structures without any difference will not be repeated.

[0080] like Figures 16A to 16B As shown, a plurality of guide walls 50 are formed at the rear end of the upper surface of the moving member 4 . The plurality of groove portions 49 arranged at predetermined intervals in the width direction constitute the plurality of guide walls 50 . A communication hole 51 communicating with the upper surface and the lower surface is provided at the front of the bottom surface of the groove portion 49 . The shaft portion 52 is formed between the guide walls 50 . The latch receiving portions 53 protrude forward from the guide walls 50 at both ends, respectively. A first lock recess 54 and a second lock recess 55...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com