A compact frame structure suitable for svg

A frame-type, compact technology, applied in the field of power transmission and distribution of the power grid, can solve the problems of large volume, partial discharge, and difficult installation of the complete set of equipment, and achieve the effects of small footprint, low cost, and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

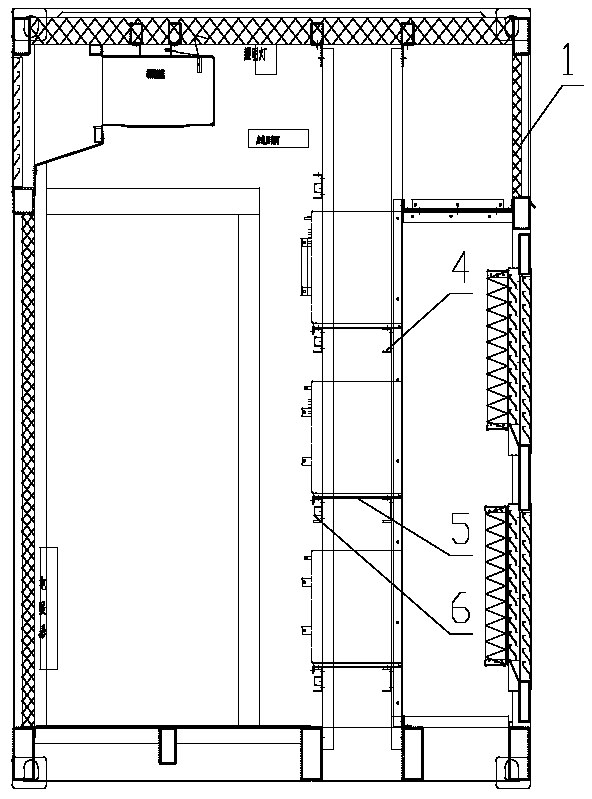

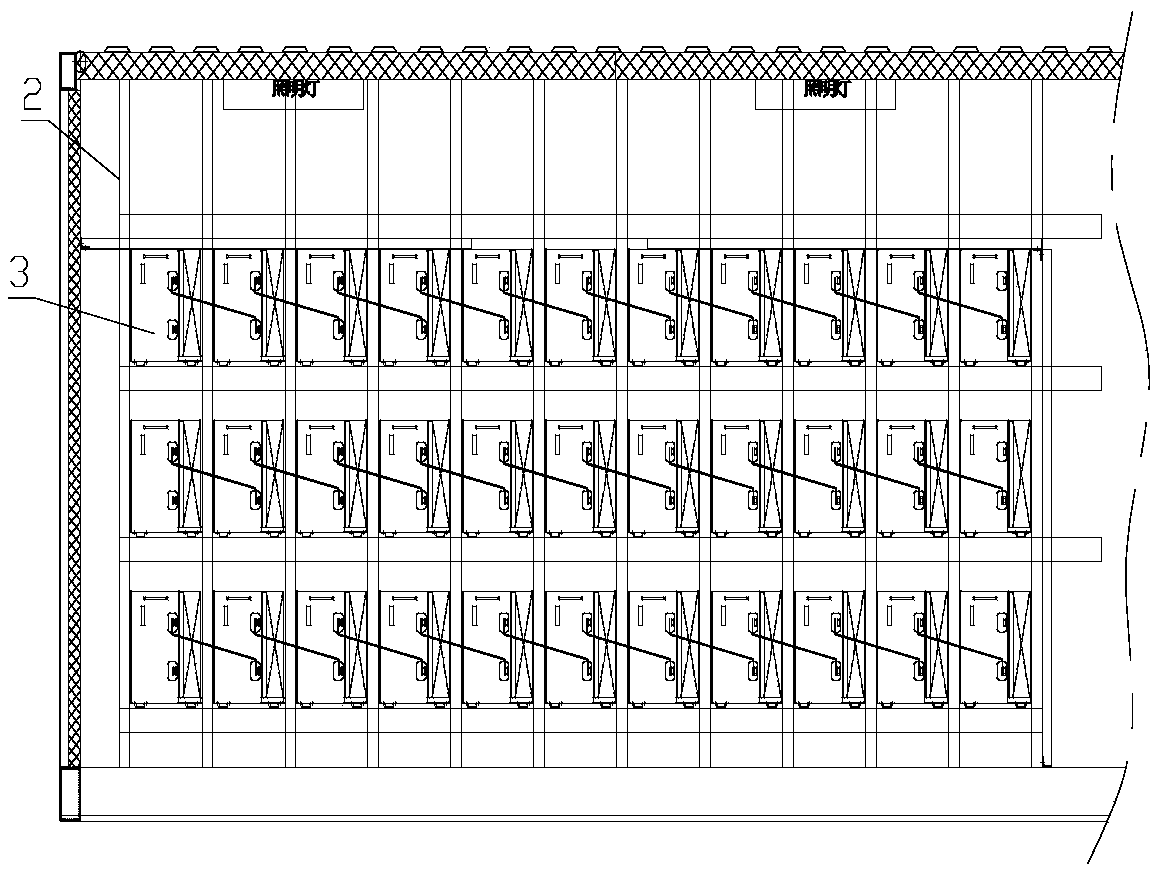

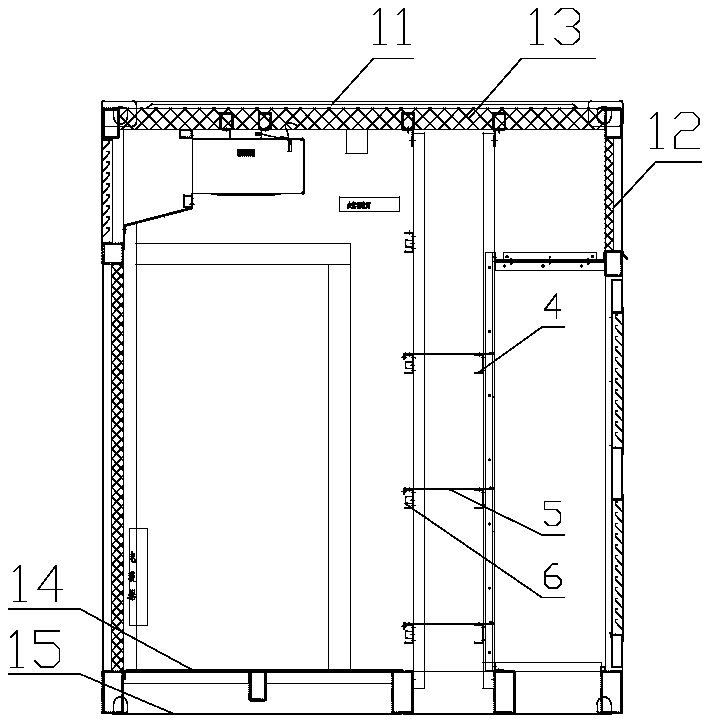

[0027] Such as Figures 1 to 2 As shown, the compact frame structure suitable for SVG of the present invention, the main components are: box body 1, hollow square tube epoxy plastic corner column 2, SVG power module 3, groove-shaped epoxy plastic corner 4. SVG module guide rail 5, wire slot 6.

[0028] The main frame of the box body 1 is welded by I-beam and rectangular steel pipe. The top plate 11 and the side plate 12 are made of hot-rolled steel plates for corrosion-resistant structure; the inner wall plate 13 is made of sound-absorbing cotton colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com