Dual-rotor flux-switching permanent-magnet motor

A magnetic flux switching, permanent magnet motor technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of low utilization rate of permanent magnets, magnetic flux leakage, etc. Volume quality, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

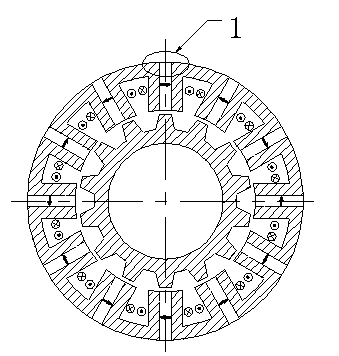

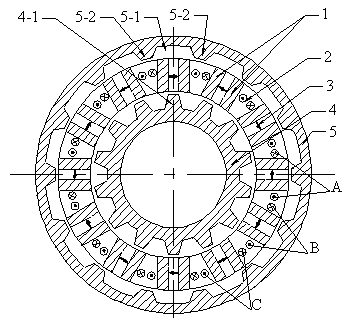

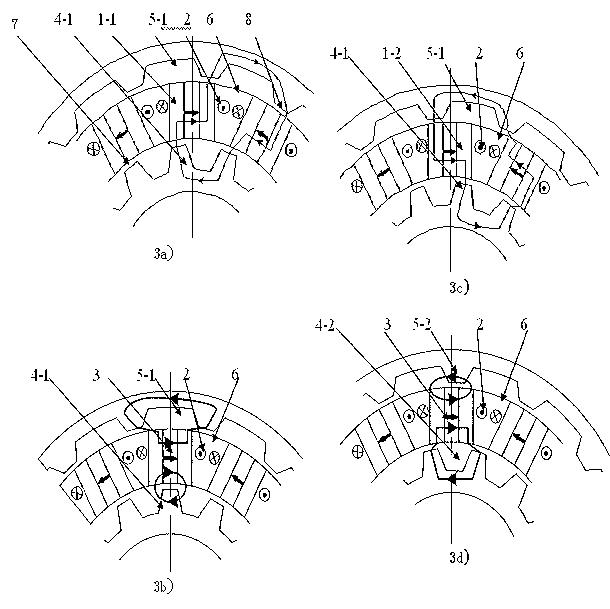

[0029] Example 1: Combining figure 2 with image 3 The dual-rotor flux switching permanent magnet motor of the present invention includes a stator and two rotors, and the speed and direction of rotation of the inner rotor 4 and the outer rotor 5 are the same.

[0030] The stator is composed of several stator modules, which form a circle. Each stator module consists of two stator core teeth 1-1, 1-2, an armature winding 2 and a permanent magnet 3. The permanent magnet 3 is located between two magnetically permeable stator core teeth 1-1 and 1-2, forming a sandwich module structure of two iron cores and permanent magnets. Two permanent magnets in adjacent sandwich structures have opposite magnetization directions. There is a through slot 6 between the two stator modules, and the armature winding 2 is inside the through slot 6 . The armature winding adopts the concentrated winding structure according to the phase sequence of A-B-C, and is wound on the interlayer module compo...

Embodiment 2

[0037] Embodiment two: see Figure 4To illustrate this embodiment, the difference between this embodiment and the dual-rotor flux switching permanent magnet motor of Embodiment 1 is that on the stator, since the stator is a sandwich module structure composed of discrete stator core teeth and permanent magnets, and the winding in the through slot The composition of the winding is not convenient for the winding of the winding, and the stator module needs to be installed and fixed by an external supporting structure. Therefore, a non-magnetically permeable beam 9 connecting the two stator modules is installed in the slot. The beam is made of non-magnetic or weakly permeable metal material with good strength, and is welded together with the stator core teeth. The through slot is divided into upper and lower layers, each layer contains a positive winding of one phase winding and a negative winding of another phase winding, and the same phase windings of the upper and lower layers c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com