Part recognition system and part recognition method

An identification method and part technology, applied in the direction of electrical components, electrical components, assembling printed circuits with electrical components, etc., can solve problems such as the inability to judge the difference in the relative position of the pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

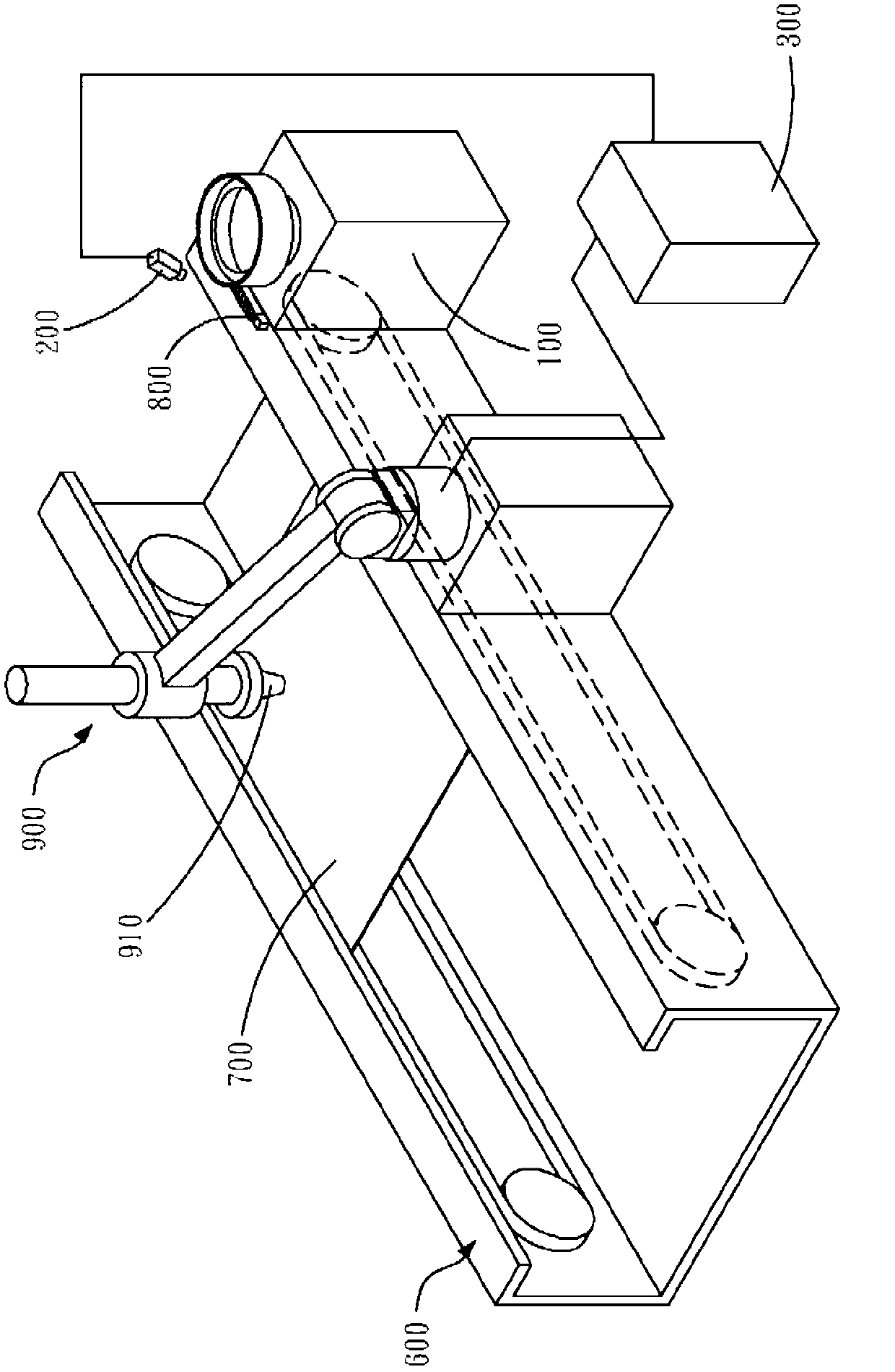

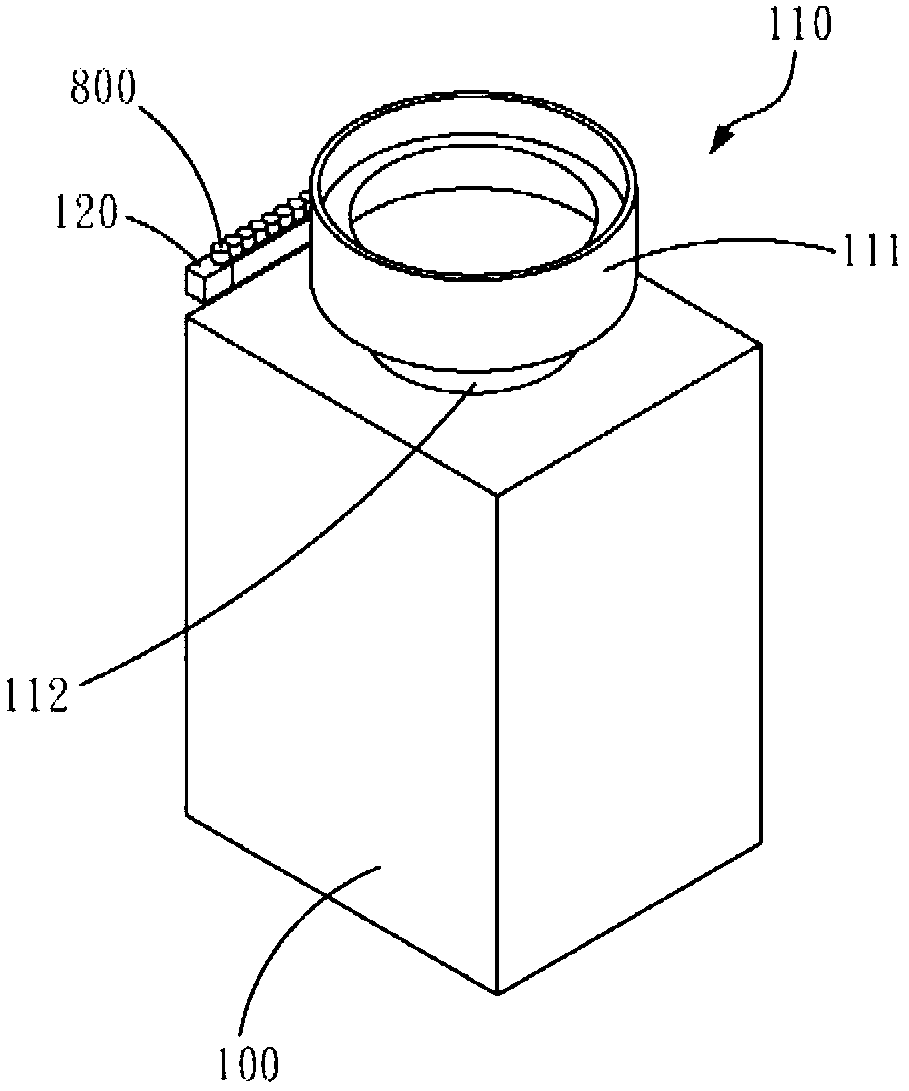

[0045] see figure 1 As shown, the part recognition system disclosed in the first embodiment of the present invention is used to generate an instruction to drive an automatic device 900 to adjust the part 800 after picking up (Pick-up) a part 800 (insertion-part). pin 830 to a predetermined position, and place the component 800 on a printed circuit board 700 .

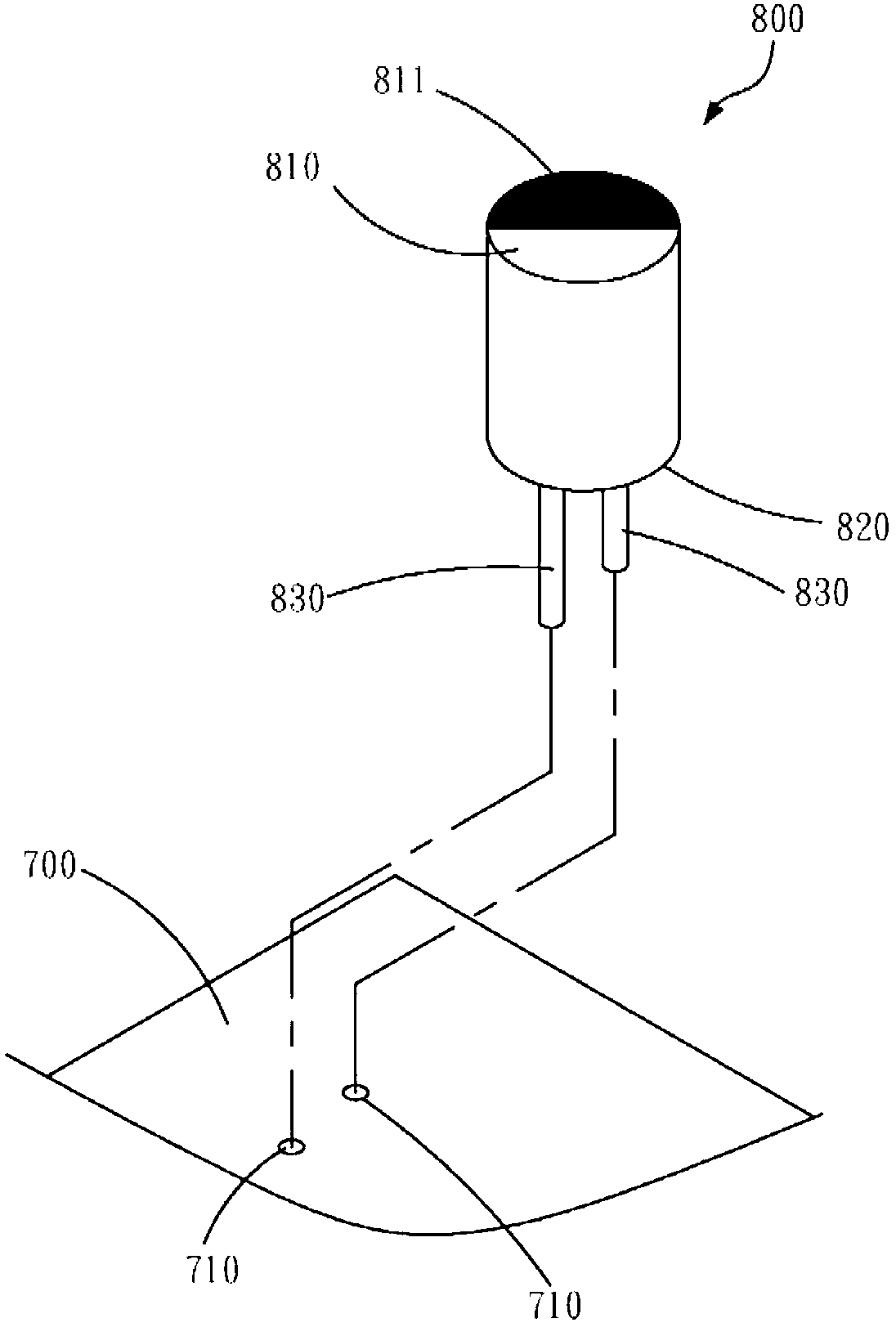

[0046] refer to figure 2 As shown, the component 800 includes a top 810 , a bottom 820 and at least one set of pins 830 disposed on the bottom 820 . The top 810 of the part 800 includes at least one positioning feature 811 . The printed circuit board 700 includes sockets 710 for inserting corresponding pins 830 . The automation device 900 picks up the part 800 and installs the part 800 on the printed circuit board 700 so that each pin 830 is inserted into the corresponding socket 710 .

[0047] Such as figure 1 The illustrated automation device 900 includes a picking unit 910 for picking up the part 800 . The pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com