Double protection control method for upward coiling process of steel coiling vehicle

A technology of double protection and control method, which is applied in the field of metallurgical rolling, can solve problems such as the occurrence of accidents, the deviation of the center line of the core and the center line of the uncoiler or coiler, and achieve collision prevention, small center deviation, and protection The effect of device security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

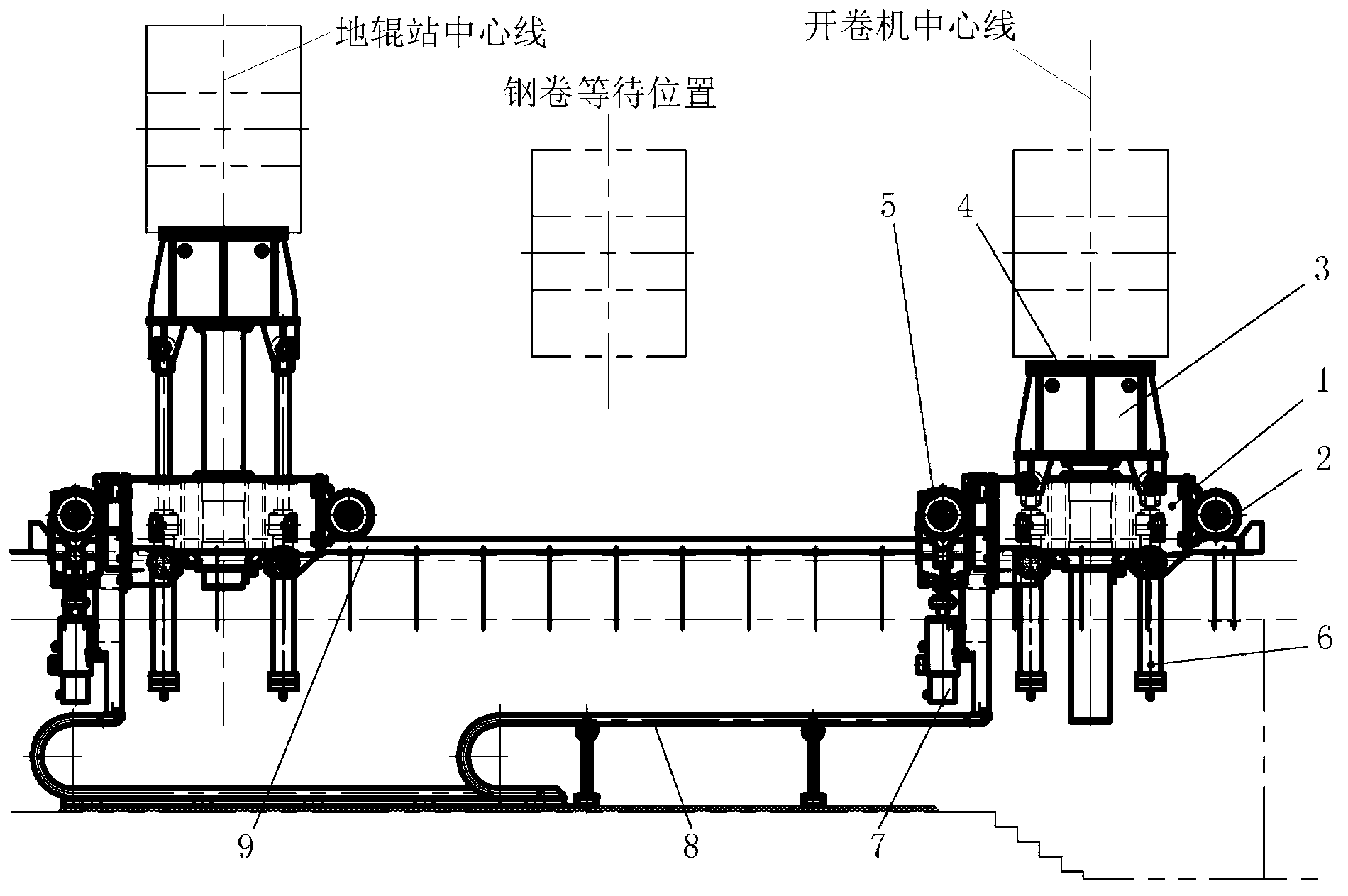

[0022] In order to facilitate the description of the roll-up process, figure 1 At the same time, a schematic diagram of the two stations of the coil car at the coil receiving position and the coil delivery position is drawn. Of course, the actual working situation can only be a single coil car, shuttling back and forth between the two positions.

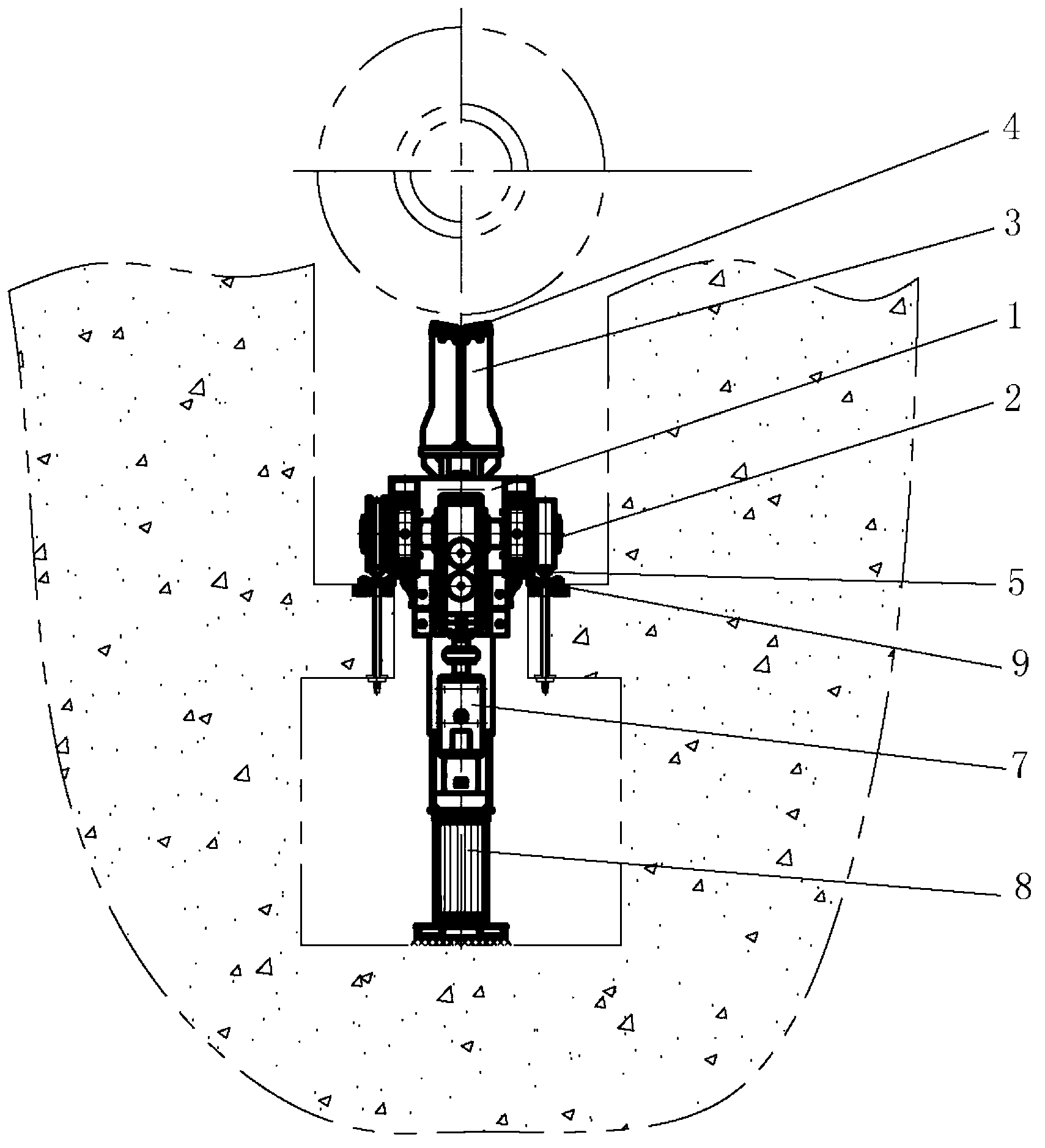

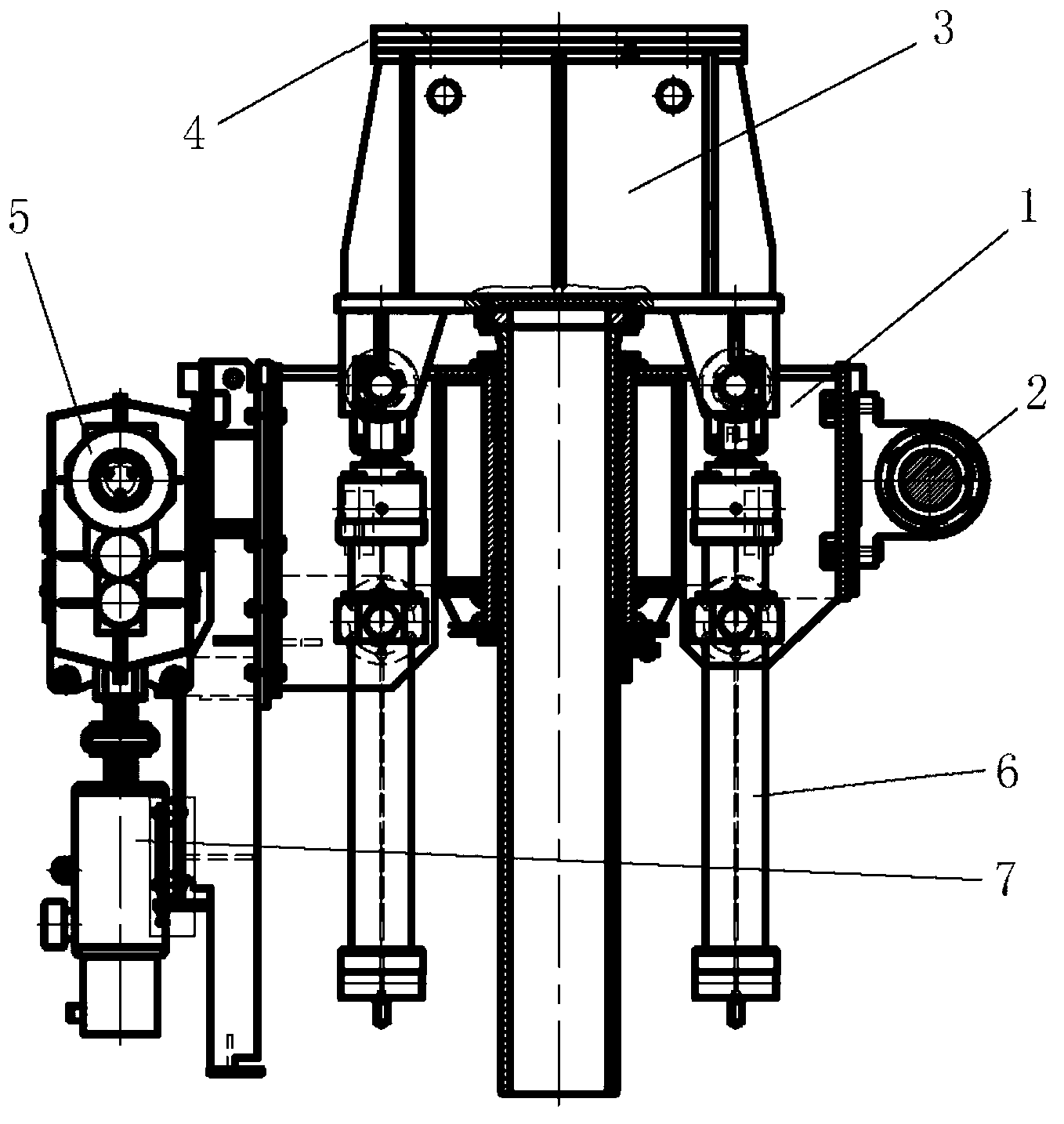

[0023] refer to figure 1 , figure 2 , image 3 The structure of the device used in the method of the present invention is that a track 9 is installed on the upper surface of the base, and a steel coil car 1 capable of laterally moving is placed on the track 9, and the wheels of the steel coil car 1 are driven by a travel drive speed reducer 6 and a travel drive motor. 7 connection; the upper part of the steel coil car 1 is provided with a lifting table 3, and the lifting table 3 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com