Universal auxiliary welding device for microwave antennas

A technology for auxiliary devices and microwave antennas, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of poor versatility and inability to fix microwave antennas, and achieve good heat dissipation, not easy to deform, and easy to adjust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

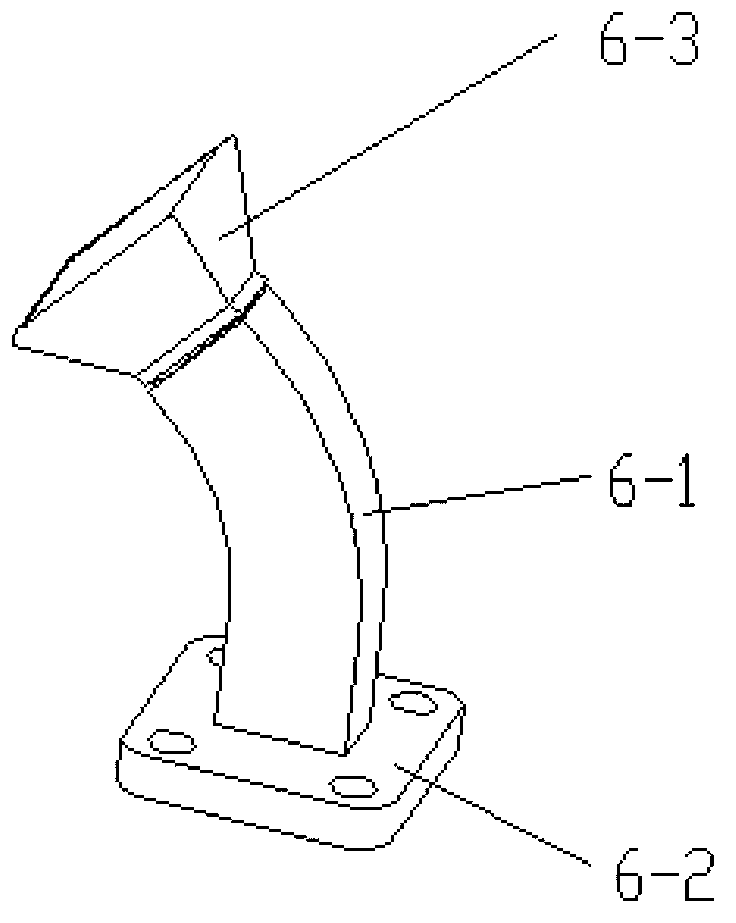

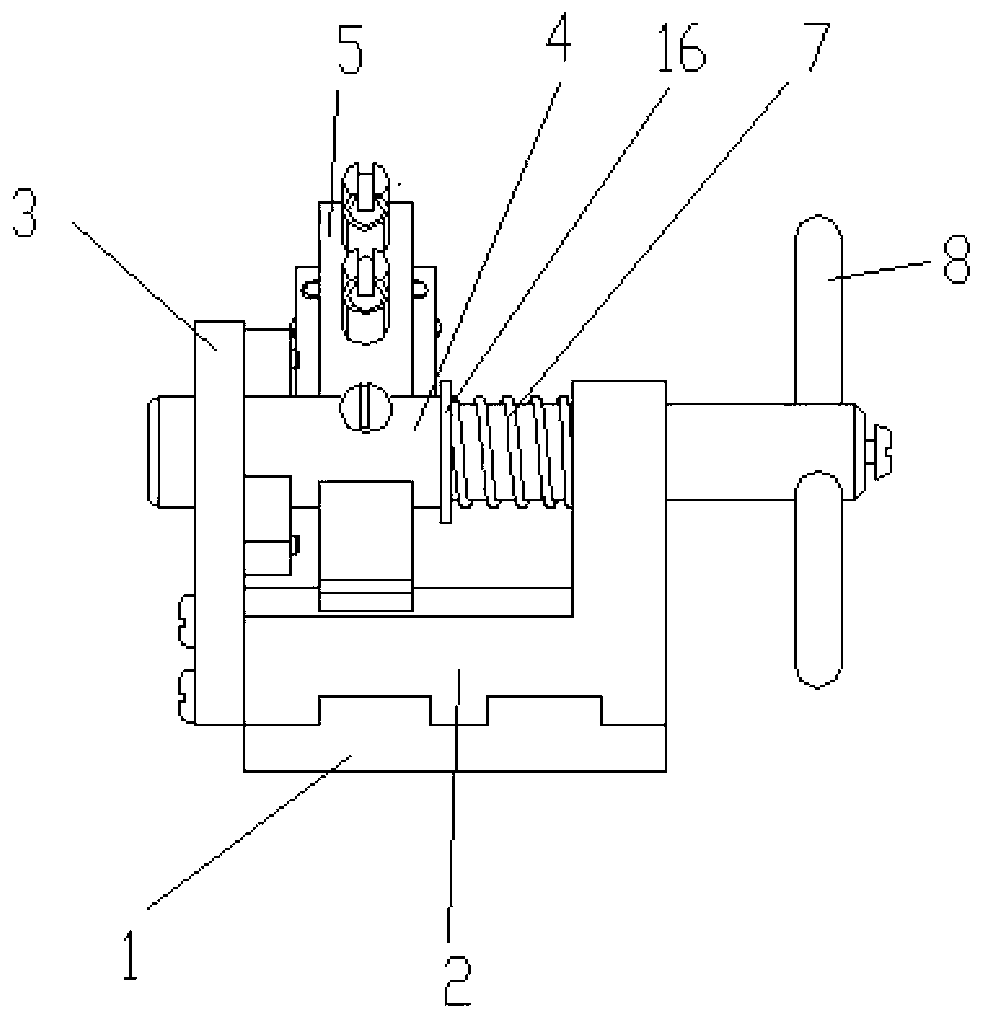

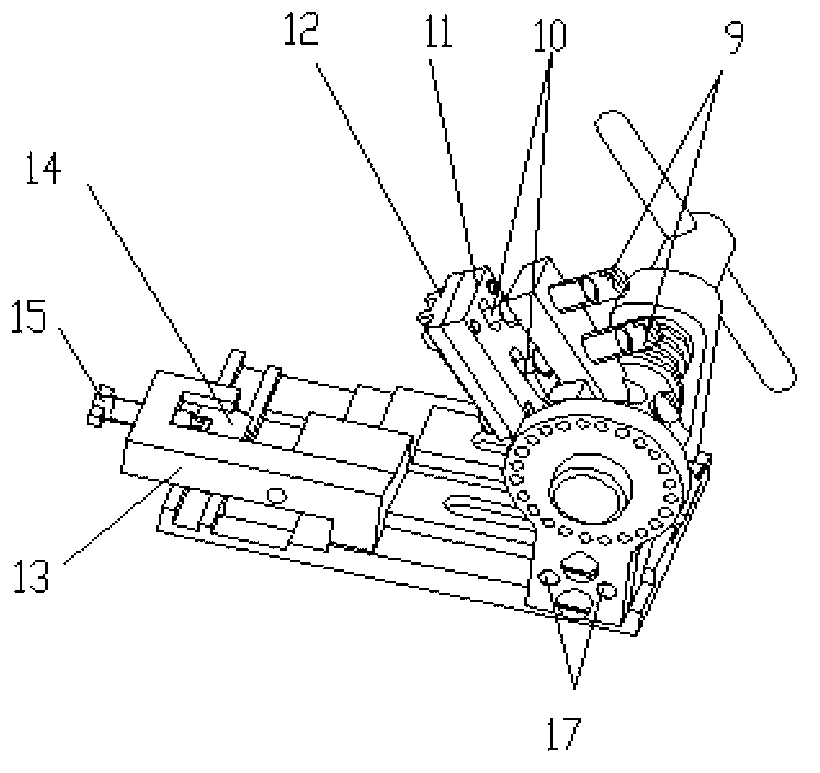

[0049] Such as figure 2 with image 3 As shown, the embodiment of the present invention includes a base 1, a bracket 2, an adjustment plate 3, a clamping plate 13, a rotating shaft 4, a sliding plate 5, an upper pressing plate 11 and a lower pressing plate 12; The base 1 moves laterally and is fixed, and the support 2 has a longitudinal shaft hole; the adjustment disc 3 is connected to the side of the support 2, and the adjustment disc 3 has a central hole and positioning holes evenly distributed along the circumference; the rotating shaft 4 is formed by an integral The vertical stepped shaft and the transverse positioning rod are perpendicular to each other. The two ends of the longitudinal stepped shaft are respectively located in the center hole of the adjustment disc and the longitudinal shaft hole of the bracket and are matched with clearance. The two ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com