Automatic die exchanging system of small pressing machine

An automatic mold change and press technology, applied in the direction of presses, forming tools, metal processing equipment, etc., can solve the problems of no standardization, large differences, different mold specifications, structures and standards, etc., to improve flexibility and adaptability, It is convenient for standardization and the expansion effect of warehouse location requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

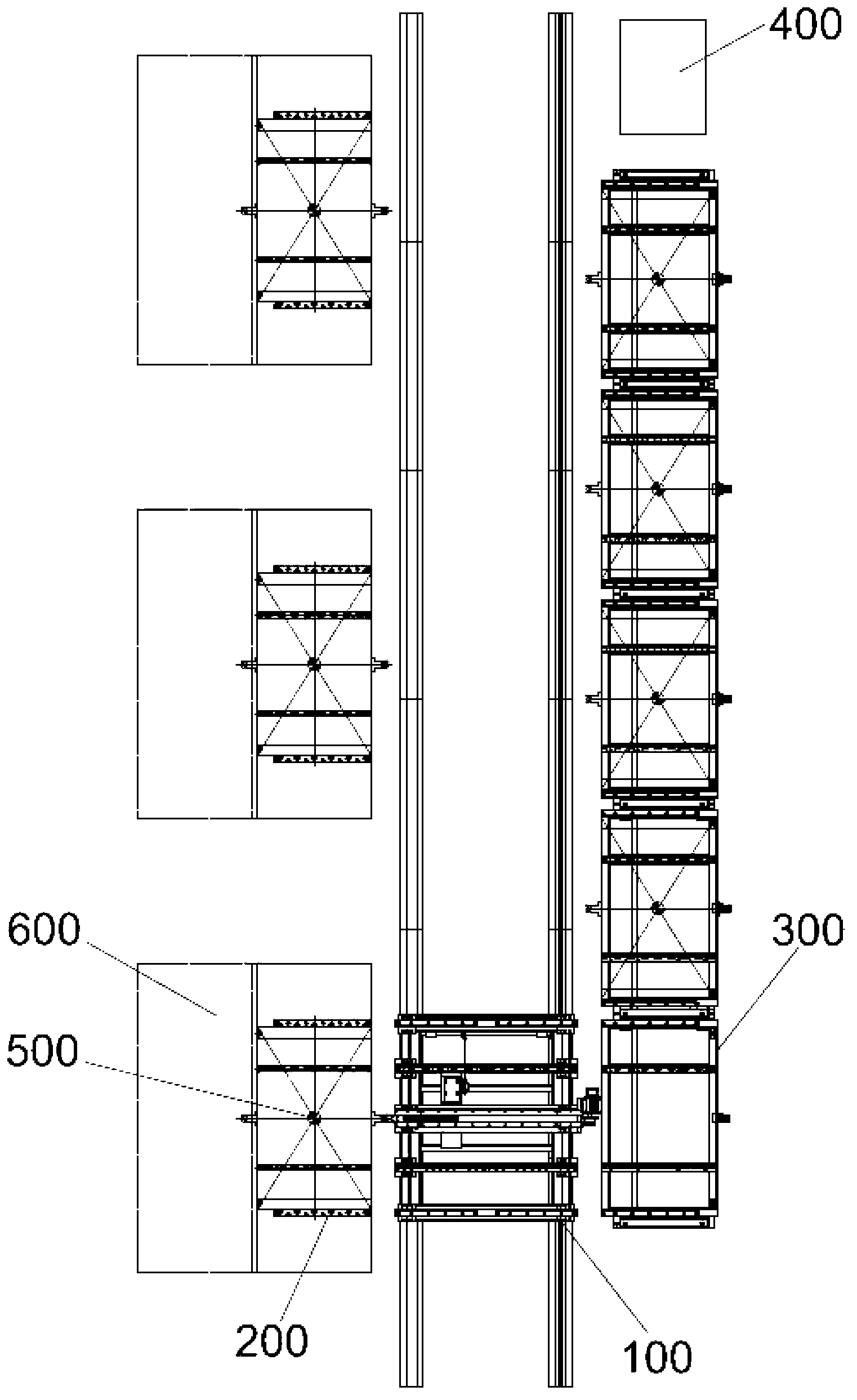

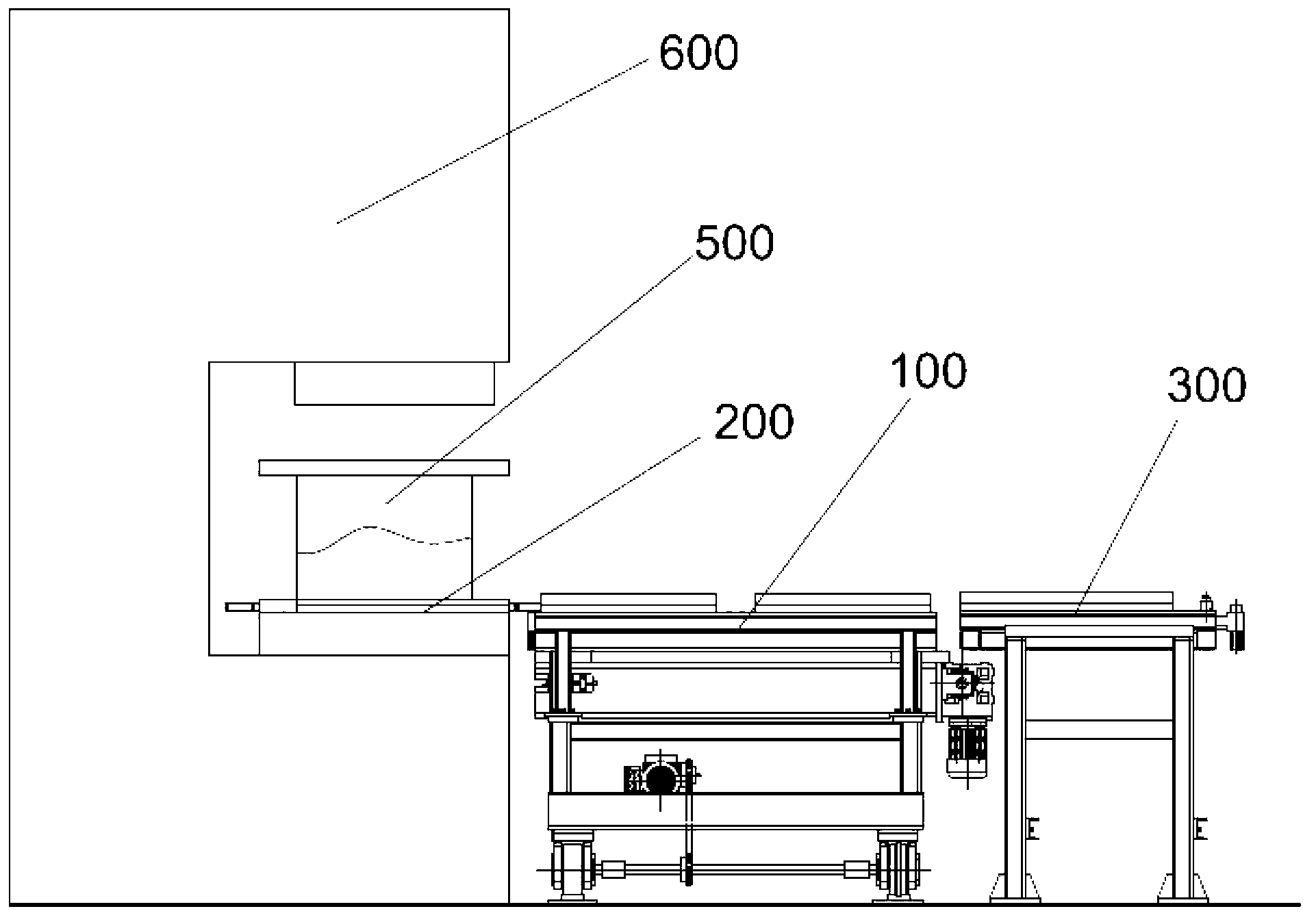

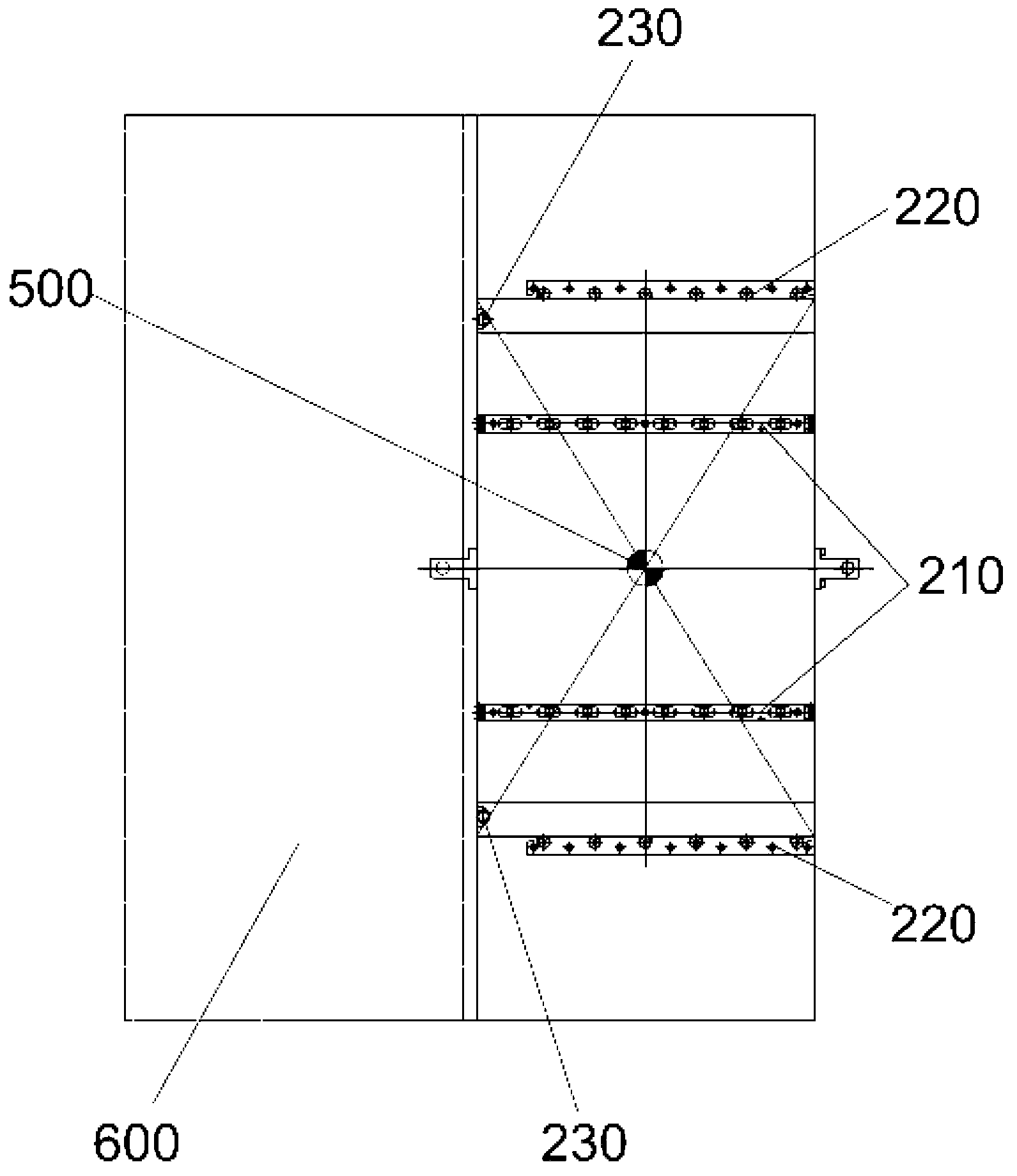

[0069] figure 1 It is the plan view of the automatic mold change system of the small press in the first embodiment, figure 2 It is a side view of the automatic mold changing system for a small press in Embodiment 1. Such as figure 1 with figure 2 As shown, the present embodiment proposes an automatic mold change system for a small press, including a mold change trolley 100 for exchanging, moving and transferring the mold 500, and for assisting in completing the mold 500 between the mold change trolley 100 and the small press. The in-machine module 200 transferred between 600, the mold library module 300 for storing molds, and the electrical system 400 for controlling and monitoring the mold exchange process; the in-machine module 200 is set on the small press 600, and the mold changing trolley 100 is movably arranged between the in-machine module 200 and the mold library module 300 , and the electrical system 400 controls and connects the in-machine module 200 and the mol...

Embodiment 2

[0113] Figure 29 It is the plan view of the automatic mold changing system of the small press in the second embodiment. Such as Figure 29 As shown, the difference between the present embodiment and the first embodiment is that the mold library module 300 and the small press 600 of the present embodiment are arranged on the same side of the ground track 125 and arranged on the same axis. Therefore, in this embodiment, the exchange of the push-pull device 130 only requires push-pull exchange in one direction, and only one hook pin is provided on the mounting block of the mold hook.

Embodiment 3

[0115] Figure 30 It is the plan view of the automatic mold change system of the small press in the third embodiment. Such as Figure 30 As shown, the difference between this embodiment and Embodiment 2 is that this embodiment is a single-machine multi-mode library exchange mode, that is, only for one small press 600 . This mode is the smallest application unit of the automatic exchange system. The small press 600 and the mold library module 300 are arranged on the same axis. This system is suitable for building an automatic exchange system for a single machine to realize automatic exchange. In addition, other automatic loading and unloading devices can be used to realize single machine The unmanned operation of the production unit constitutes the stamping FMS system.

[0116] Of course, in other embodiments, the small presses can also be installed on both sides of the mold changing trolley at the same time, and details will not be repeated here.

[0117] It can be seen fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com