Automatic demisting system for front windshield inner surface of automobile

A front windshield and inner surface technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as accidents, dangers, and affecting the driver's sight, and achieve the effect of reliable control and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

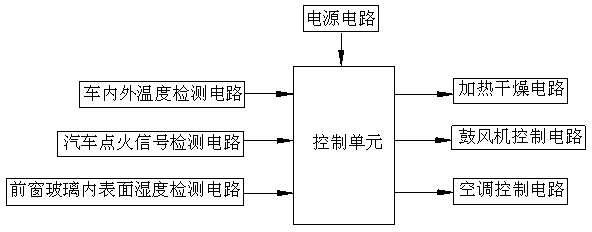

[0021] Such as figure 1 As shown, the automatic defogging system for the inner surface of the windshield of the automobile in the present embodiment includes a control unit, and the control unit is respectively connected with the power supply circuit, the automobile ignition signal detection circuit, the blower control circuit, the air conditioner control circuit, and the inner surface of the windshield. The humidity detection circuit, the temperature detection circuit inside and outside the car, and the heating and drying circuit are connected.

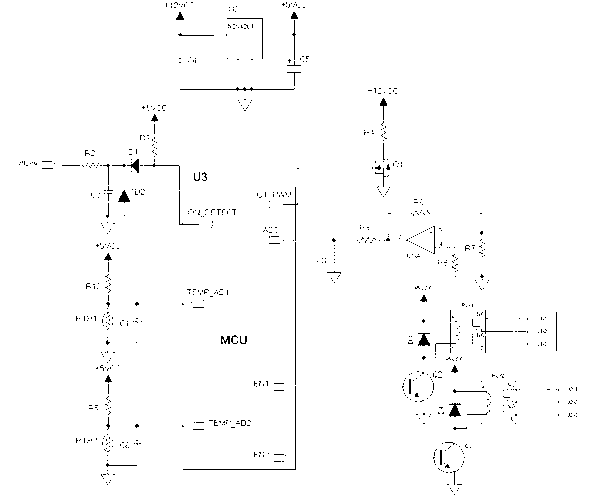

[0022] Such as figure 2 As shown, each circuit principle in this embodiment is as follows:

[0023] The inside and outside temperature detection circuit includes an outside temperature detection unit and an inside temperature detection unit. The outside temperature detection unit includes an outside temperature sensor RTH1. One end of the outside temperature sensor RTH1 is grounded, and the other end is passed through a first The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com