Automatic Feeding System Using Vacuum Feeder

A vacuum feeding machine and automatic feeding technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high power consumption, filter clogging, and slow material conveying speed, so as to reduce mechanical failures, reduce mechanical actions, The effect of improving the conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

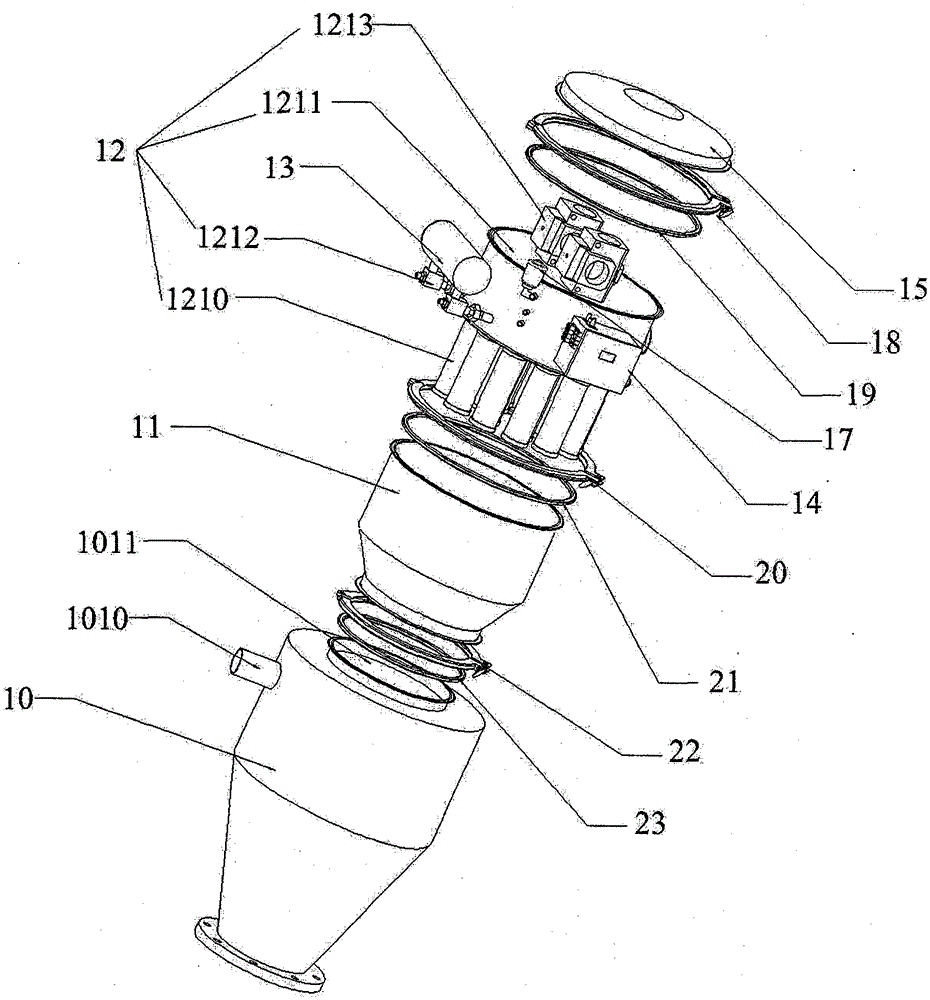

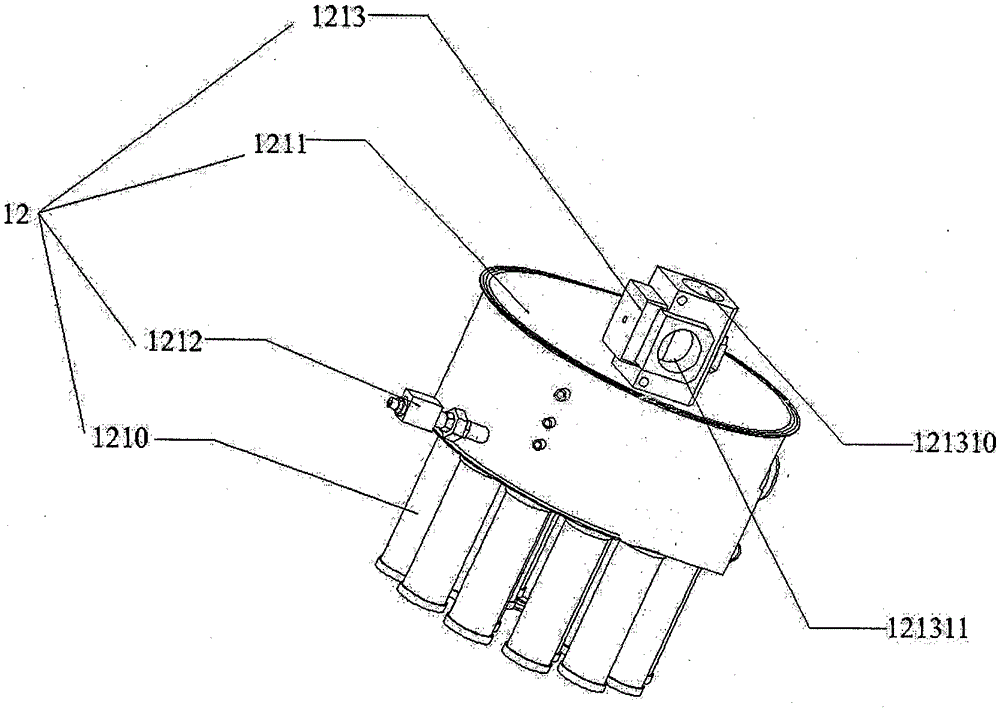

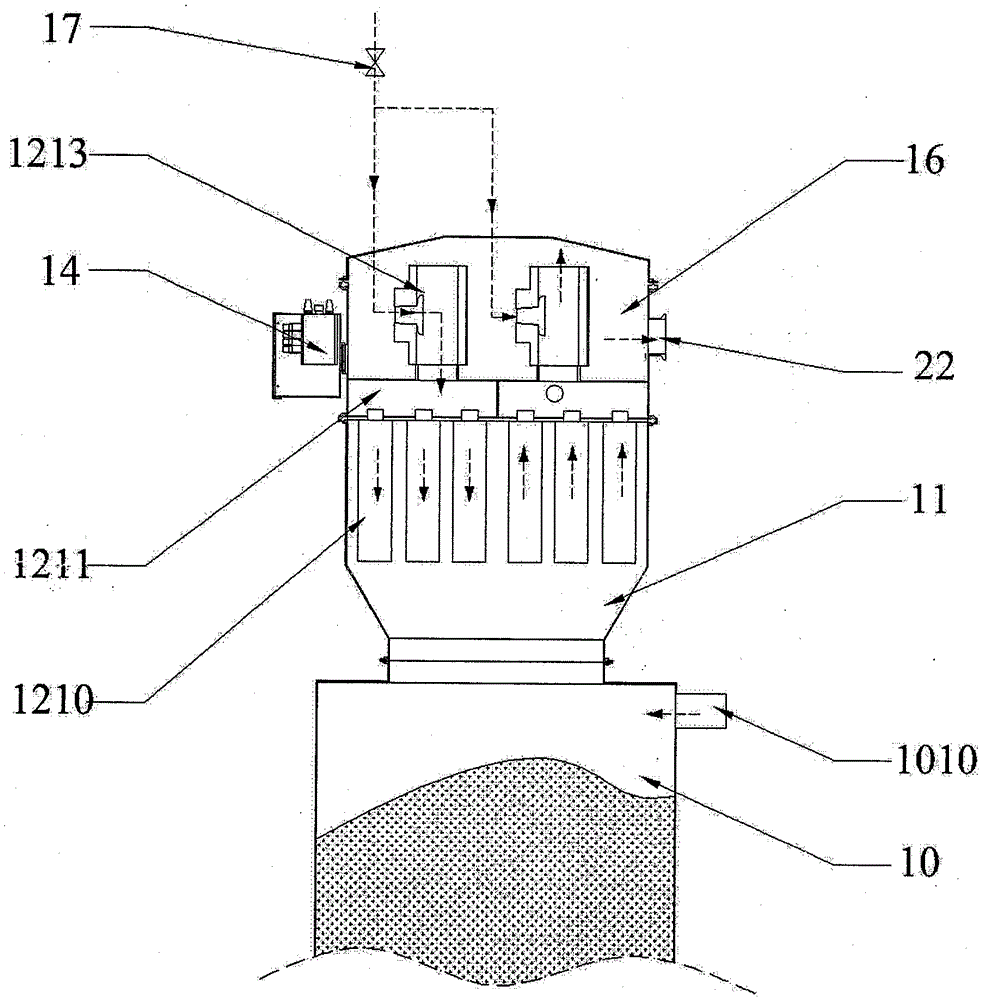

[0040] The vacuum feeder provided by the present invention includes a storage tank 10 , a filter chamber 11 , a controller 14 , a top cover 15 , an air regulating valve 17 , an air cannon 13 and at least two working groups 12 . The concrete structure of each working group 12 is: comprise filter set 1210, control chamber 1211, three-way air control valve 1213 and exhaust valve 1212; The valve 1212 communicates; the three-way air control valve 1213 is provided with a first port, a second port 121310 and a third port 121311 , and the upper end of the control chamber 1211 communicates with the first port of the three-way air control valve 1213 .

[0041] The storage tank 10 is provided with a feed port 1010 and an air intake 1011, and the storage tank 10 communicates with the filter chamber 11 through the air intake 1011; the filter chamber 11 communicates with the lower end of the filter group 1210 of the working group 12; the top cover 15 communicates with the control One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com