Embedded bolt for slab type ballastless track turnout of high-speed railway

A ballastless track and embedded bolt technology, applied in the field of embedded parts, can solve the problems of easy loosening, low precision, and easy corrosion of welding points, so as to increase the fixing strength, increase the service life, and prevent loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the drawings.

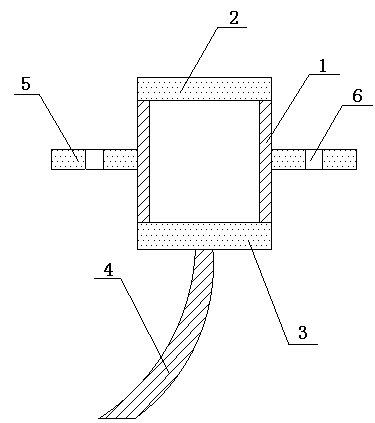

[0012] Such as figure 1 Shown is a high-speed rail plate type ballastless track switch plate embedded bolts, including bent steel bolts 4, a casing 1 and a protective cover 2. One end of the casing 1 is connected with a protective cover 2, and the other end of the casing 1 passes through a connecting plate 3. Bending steel bolts 4 are connected, a supporting plate 5 is symmetrically provided on the side of the casing 1, and screw holes 6 are opened on the supporting plate 5. Preferably, the outer surfaces of the bent steel bolts 4, the casing 1, the protective cover 2, the connecting plate 3 and the supporting plate 5 are all provided with an anticorrosive layer; the casing 1 and the protective cover 2, the casing 1 and the connecting plate 3, the connection The connection relationship between the plate 3 and the bending steel bolt 4, the sleeve 1 and the support plate 5 is all weldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com