Reactive muffler structure with combination of perforated pipes and narrow-slit resonant cavities

A technology of resistant noise reduction and perforated tubes, which is applied in the direction of noise reduction devices, machines/engines, mechanical equipment, etc., can solve the problems of general noise reduction effect, enhanced acoustic impedance, high pressure, etc., and achieve simple manufacturing process and enhanced acoustic impedance , the effect of small pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments.

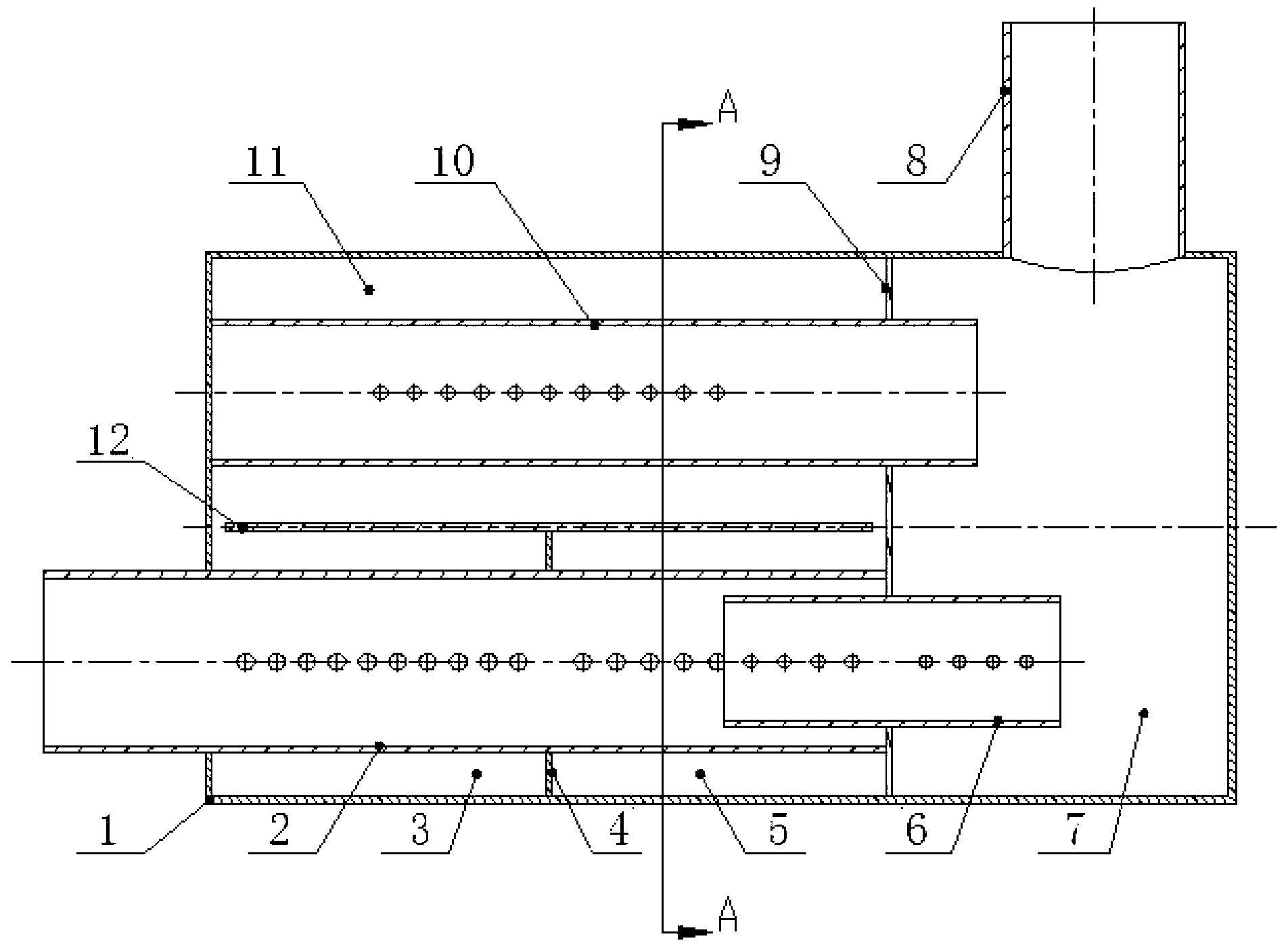

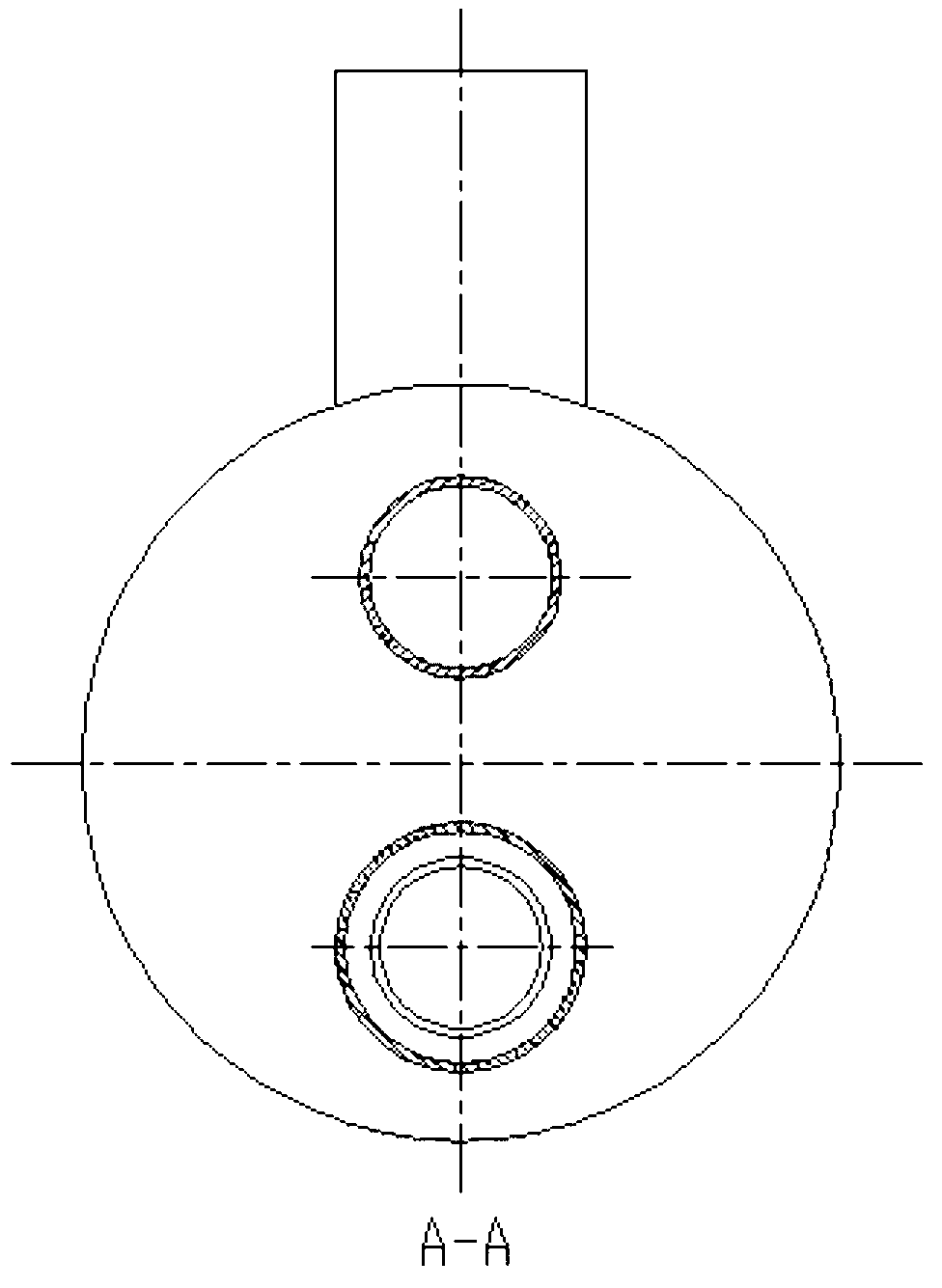

[0019] figure 1 As shown, the described structure of a resistant muffler combining a perforated tube and a narrow slot resonant cavity includes a cylinder body 1, an air inlet tube 2, an air outlet tube 8, a straight-through perforated tube 6, a cross-flow perforated tube 10, a transverse partition 12, and a longitudinal Partition plate I4 and longitudinal partition plate Ⅱ9; the cylinder body 1 is divided into four independent chambers through horizontal partition plate 12, longitudinal partition plate Ⅰ4 and longitudinal partition plate Ⅱ9: chamber Ⅰ3 and chamber Ⅱ5 , Chamber III11 and chamber IV7; the air inlet perforated pipe 2 and the straight-through perforated pipe 6 are coaxially offset, and the chamber IV7 is directly connected to the inlet pipe 2 through the straight-through perforated pipe 6; the inlet perforated pipe 2 is The longitudinal partition 4 is div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com