Spring end cover of exhausting brake butterfly valve and exhausting brake butterfly valve

A technology of exhaust brake and butterfly valve, which is applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of reduced sensitivity, lagging and failure of exhaust brake braking effect, etc., to prevent pollution, prevent random disassembly, The effect of preventing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

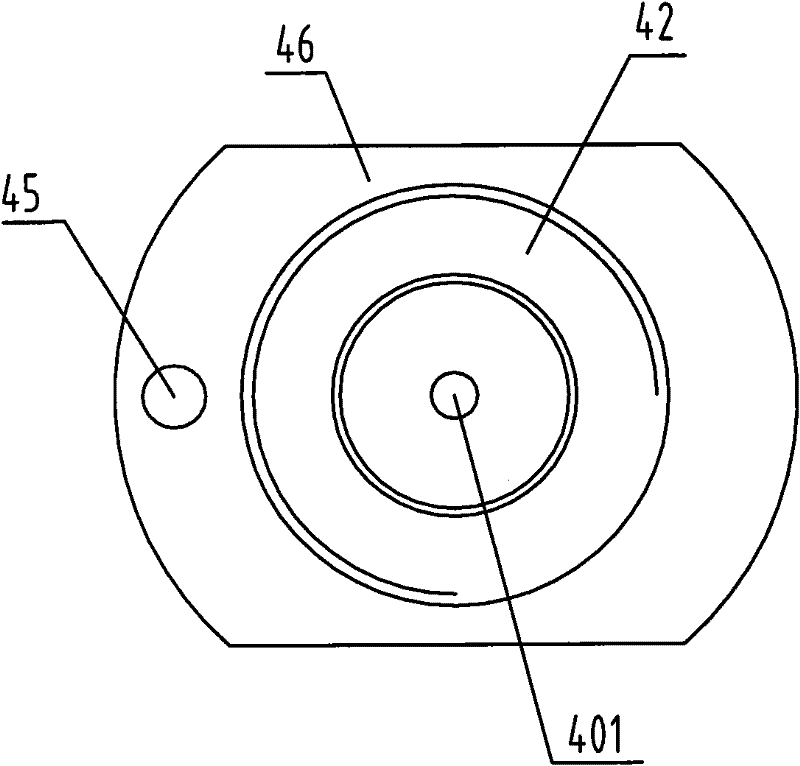

[0038] figure 2 It is a structural schematic diagram of Embodiment 2 of the spring end cap of the present invention. In order to better ensure the smoothness of the inner chamber of the pressure limiting device housing and the atmosphere, more effectively regulate the exhaust back pressure of the engine and dissipate heat in time, the first vent hole 401 can be opened as described in the first embodiment above. The quantity is one, and the opening position is at the center of the end face of the top cover. Such as figure 2 As shown, there may be a plurality of first vent holes 401 as required, which are opened symmetrically on the end surface of the top cover 43 .

[0039] Other features of this embodiment are the same as those of Embodiment 1, refer to Embodiment 1, and will not be repeated here.

Embodiment 3

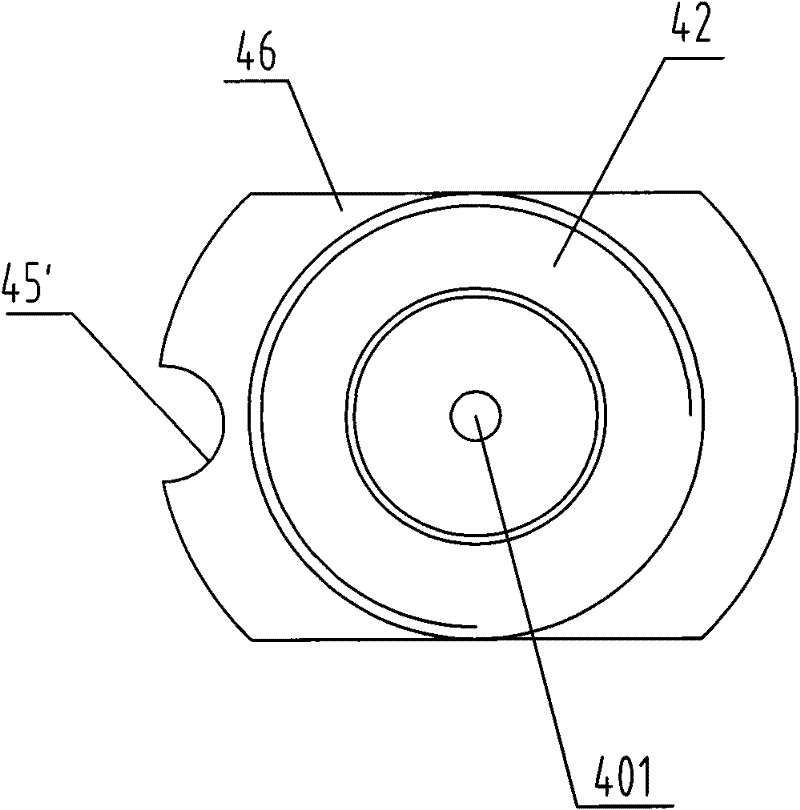

[0041] image 3 It is a structural schematic diagram of Embodiment 3 of the spring end cap of the present invention. Such as image 3As shown, as a more preferred solution, on the basis of the first embodiment, a second air hole 402 is opened on the end surface of the top cover 43 , which is opened symmetrically around the periphery of the first air hole 401 .

[0042] Other features of this embodiment are the same as those of Embodiment 1, refer to Embodiment 1, and will not be repeated here.

[0043] Spring end cover embodiment four

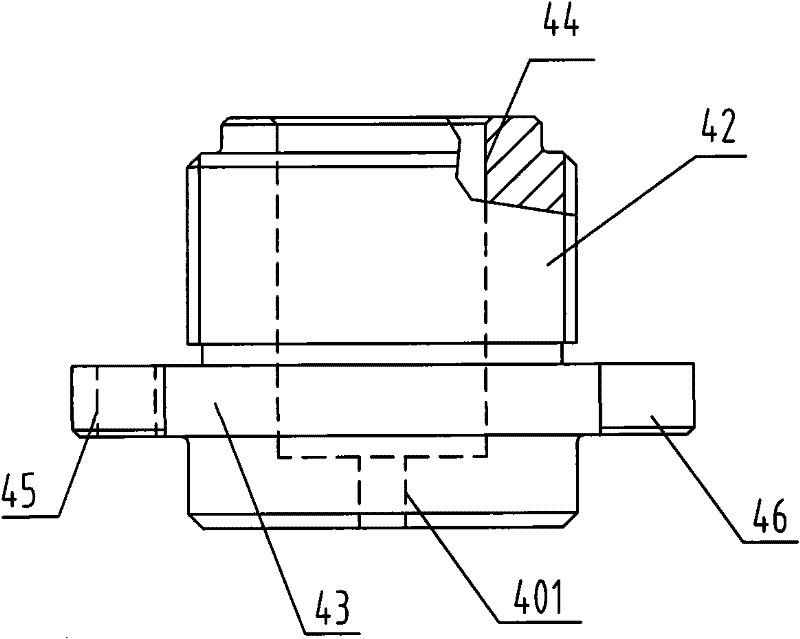

[0044] Figure 4 It is a structural schematic diagram of Embodiment 4 of the spring end cap of the present invention. On the basis of the second embodiment, according to the requirements of the number of springs in the pressure limiting device, the inner cavity 44 of the spring end cover can be set as a stepped shape in addition to being set as a blind hole. Such as Figure 4 As shown, the inner cavity 44 of the top cover 43 is a stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com