Blower impeller

A technology of blower blades and blades, which is applied in the field of blowers, can solve problems such as poor heat dissipation performance of blowers, inability to cool the motor, and serious heating of the motor, etc., and achieve the effects of facilitating heat dissipation, increasing service life, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

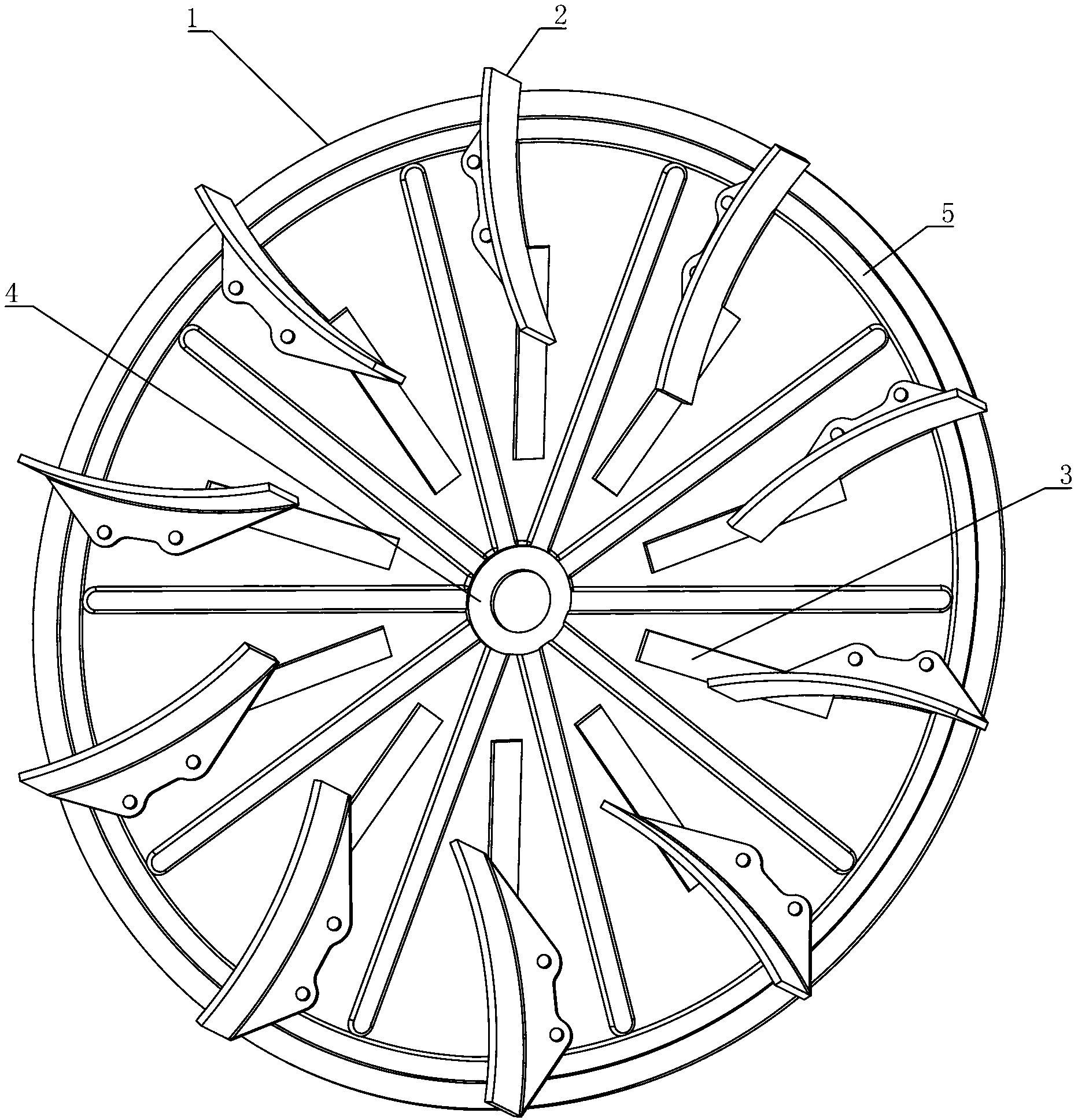

[0011] Such as figure 1 As shown, a blower impeller includes a central disk 1 and blades 2 fixedly connected to the central disk 1, the blades 2 are evenly distributed along the circumference of the central disk 1, and the central disk 1 is provided with a plurality of square The openings 3 are uniformly distributed along the circumference of the central disk 1 . As a preference of the present invention, the middle part of the central disk 1 is stamped with a recessed part 4 for easy installation of bolts or washers. As a preference, an annular groove 5 is stamped and formed close to the edge of the central disk 1 . The central disk 1 of the present invention is provided with a plurality of square holes 3, the wind that enters from the blower front can be blown to the motor from the square holes 3, and the motor can be cooled, and the temperature of the motor can be reduced, which is beneficial to the motor. Heat dissipation can effectively improve the service life of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com