Metal sealed butterfly valve without pin connection

A metal seal, pin connection technology, applied in shaft seals, lift valves, valve details, etc., can solve problems such as easy falling off and loose parts, and achieve the effect of eliminating friction, good sealing and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

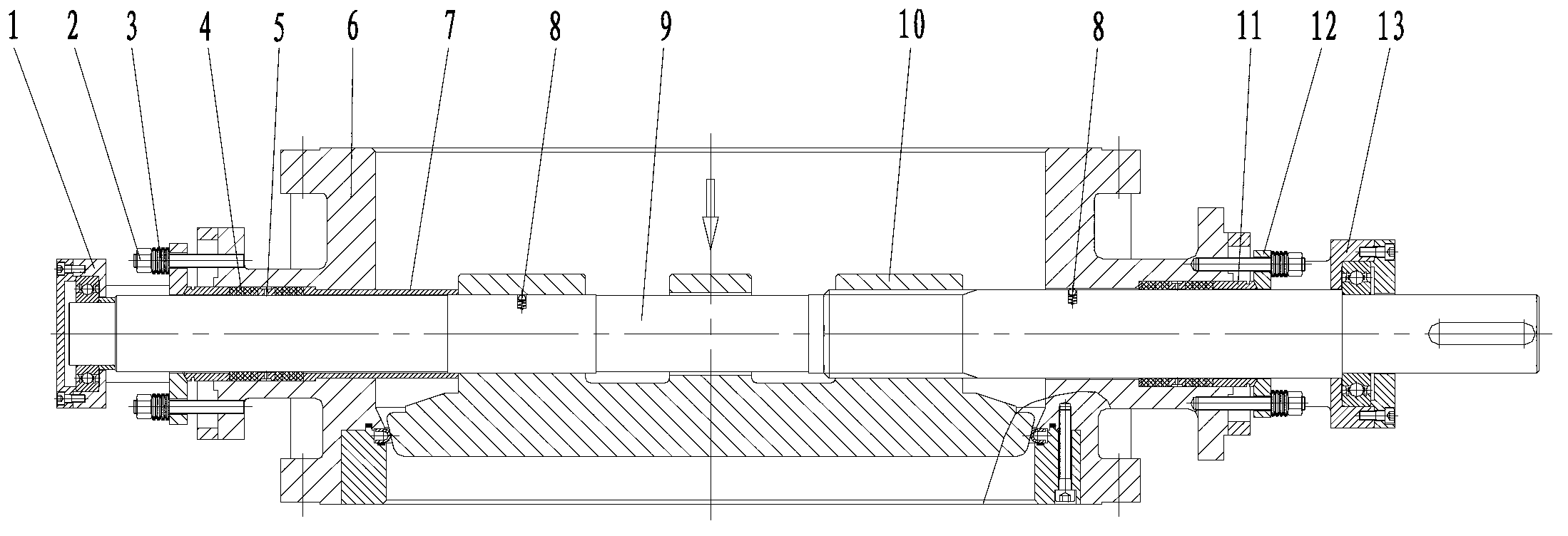

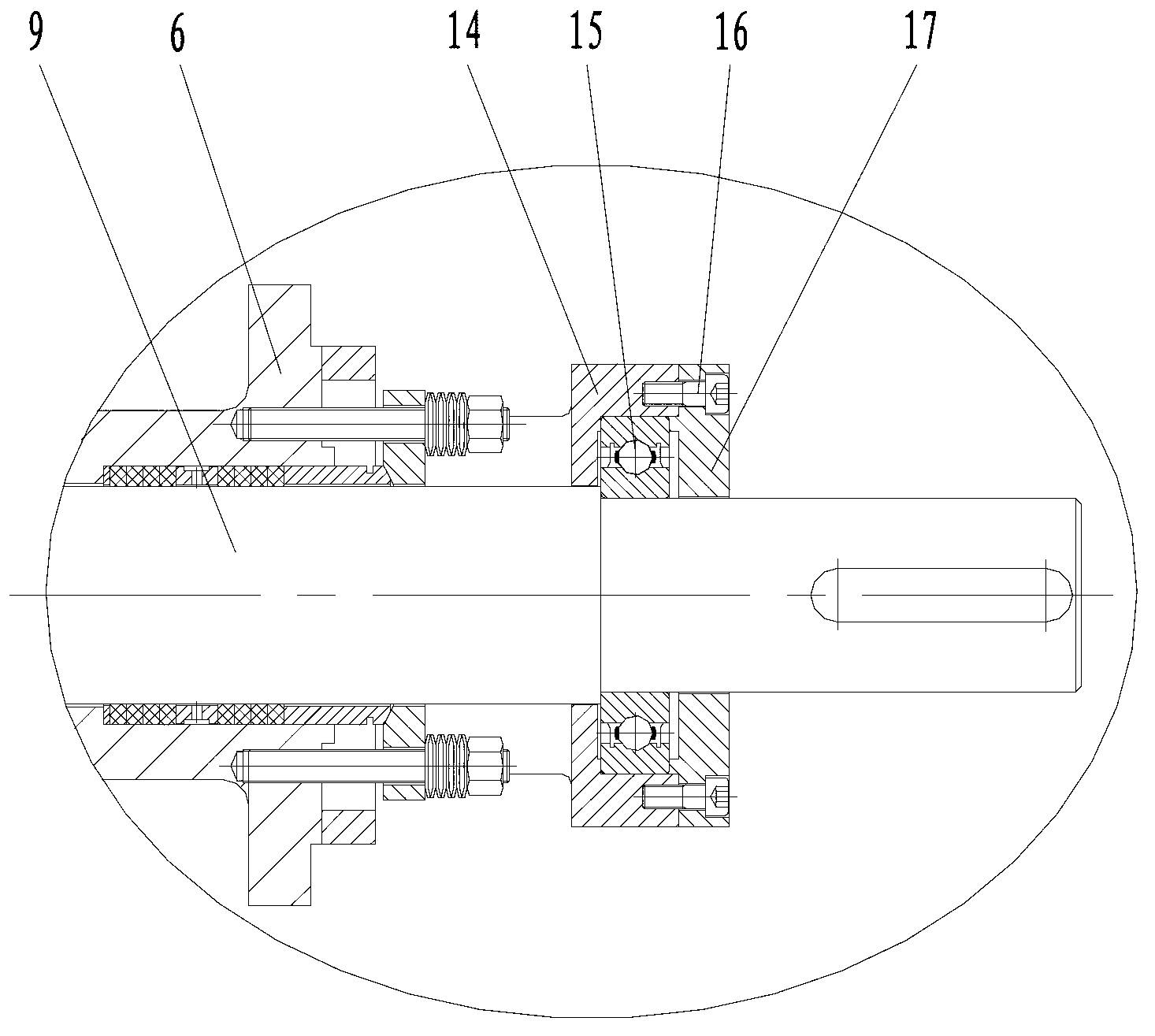

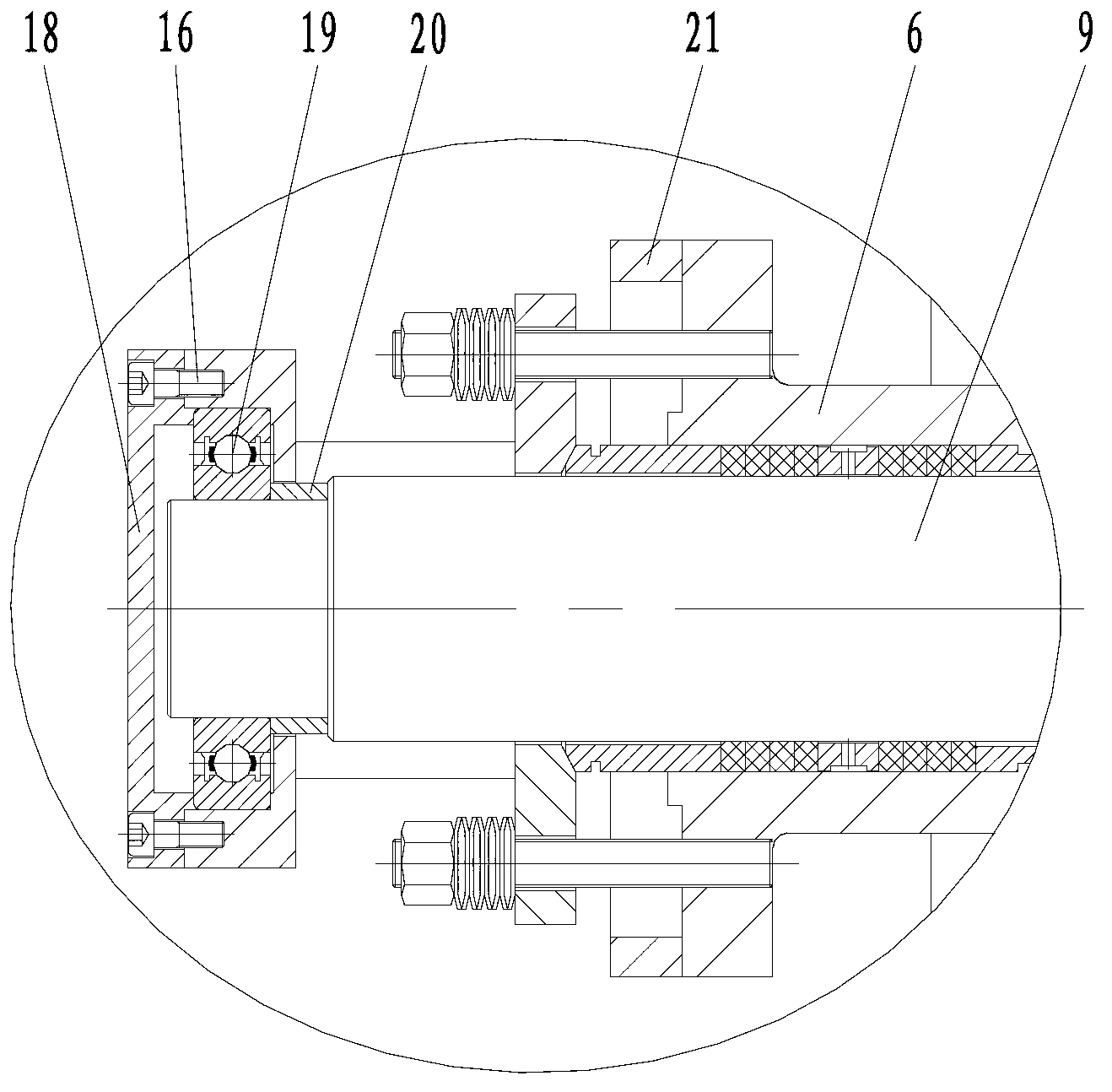

[0021] refer to figure 1 , the pinless metal seal butterfly valve of the present invention includes a rear bearing seat assembly 1, a pressure plate bolt and a nut 2, a pre-tightened butterfly spring 3, a packing 4, a packing spacer 5, a valve body 6, a limit sleeve 7, an antistatic device 8, Valve stem 9, valve plate 10, packing gland 11, packing pressure plate 12, front bearing seat assembly 13, the rear bearing seat assembly 1 and front bearing seat assembly 13 are respectively placed outside the two ends of the valve body 6 packing hole, and screwed And the positioning pin is fixedly connected with the valve body, the valve stem 9 is positioned and driven through the bearings in the rear bearing seat assembly 1 and the front bearing seat assembly 13, which greatly reduces the friction of the valve and reduces the opening and closing torque of the valve . The valve body 6 is integrally cast or forged, the filler 4 is installed in the filler hole of the valve body 6, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com