LED (Light Emitting Diode) down lamp

A technology for LED downlights and radiators, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of high production cost, inconvenient installation and maintenance, affecting the service life of LED lights, etc. Easy to combine and maintain, prolong service life, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

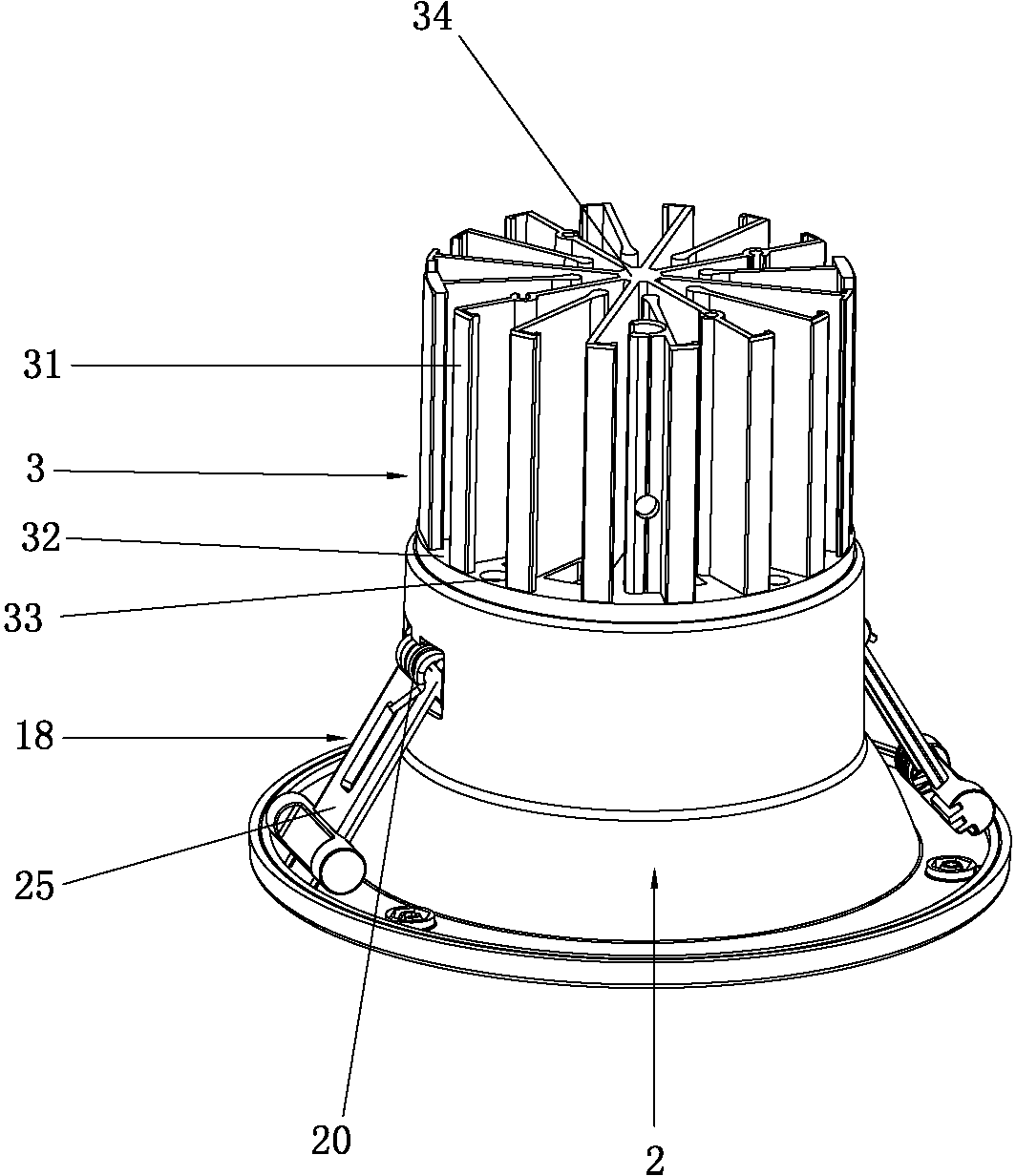

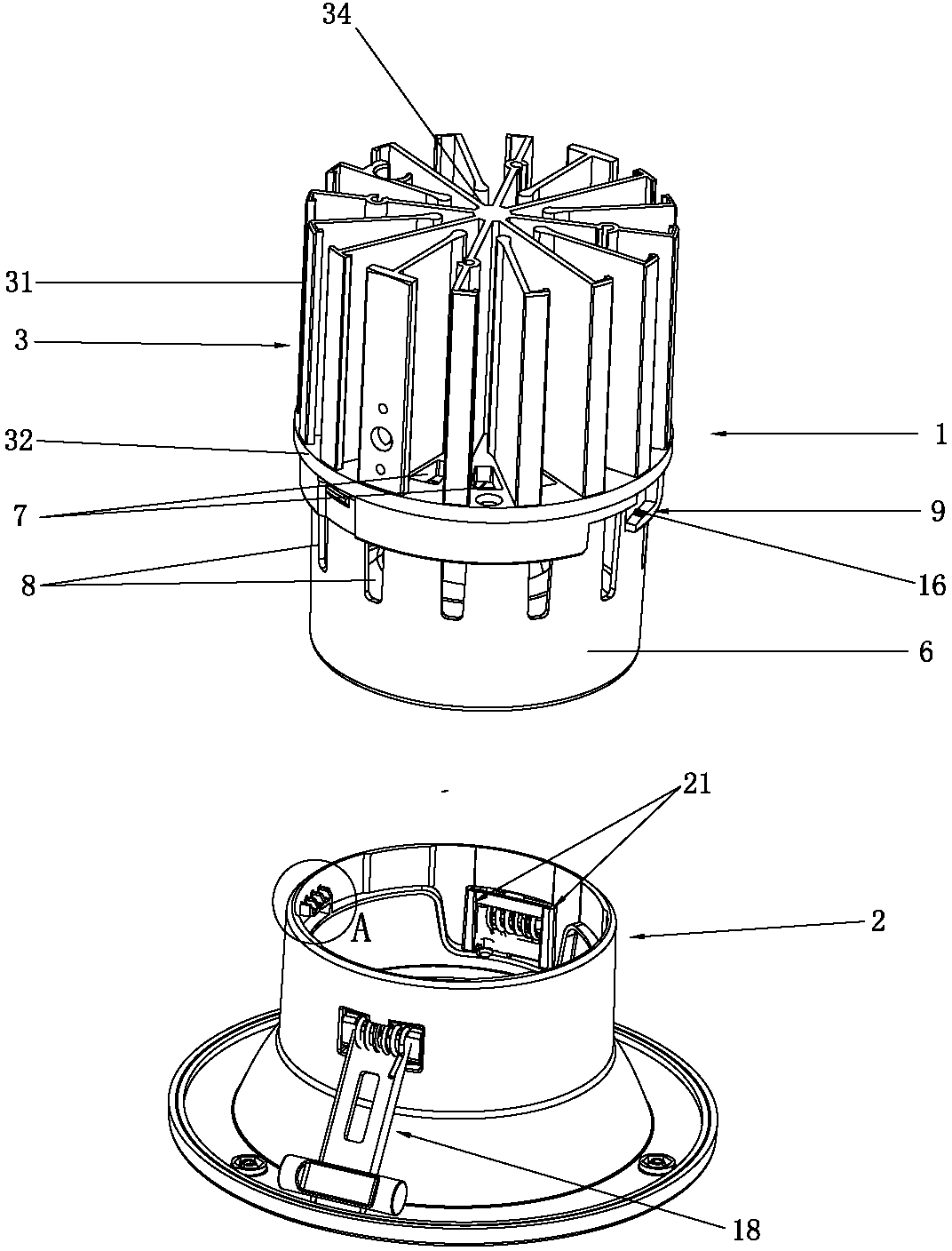

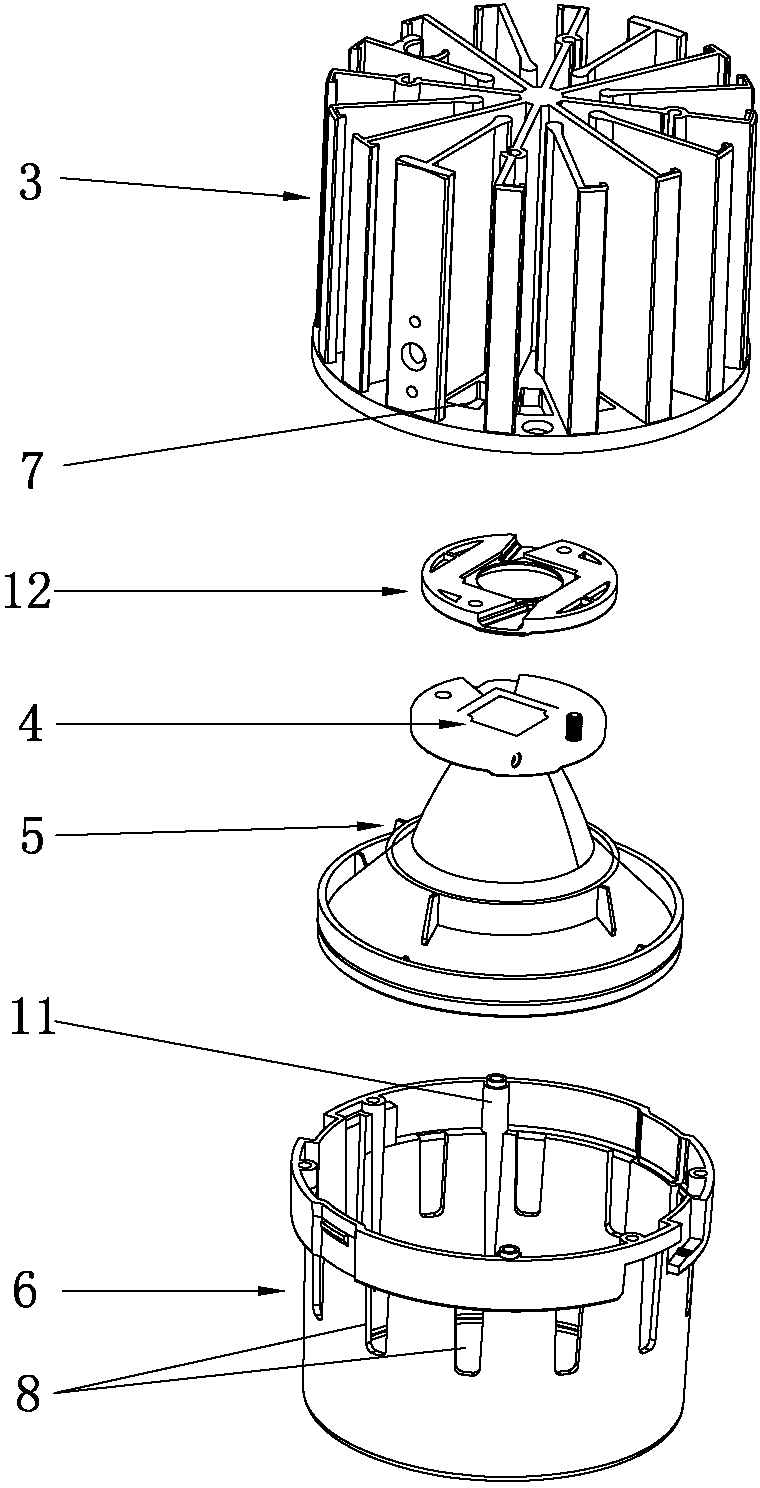

[0036] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. see Figure 1 to Figure 6 , the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] An LED downlight in this embodiment includes a light engine module 1 and a cover body 2, the light engine module 1 includes a radiator 3, a light source 4, a reflector 5 and a housing 6, and the radiator 3 and the housing 6 The upper end of the light source 4 is connected, the reflector 5 is connected with the lower end of the light source 4, and the light source 4 and the reflector 5 are installed in the inner cavity of the housing 6, and the upper end of the housing 6 is fixedly connected with the radiator 3, so The heat sink 3 is provided with a heat d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com