Light boiler wall of steam-injection boiler for oil field

A technology for steam injection boilers and furnace walls, which is applied in combustion methods, lighting and heating equipment, combustion equipment, etc., can solve problems such as unbearable loads, heavy furnace walls, and increased load on offshore platforms, saving labor costs and shortening Installation cycle, the effect of saving limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

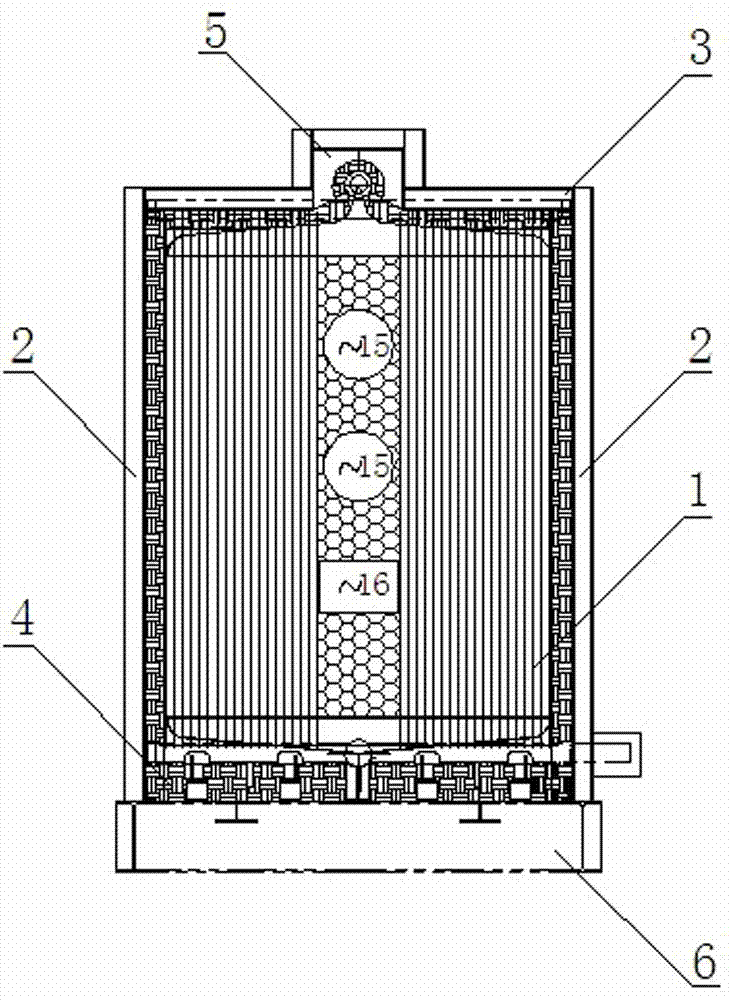

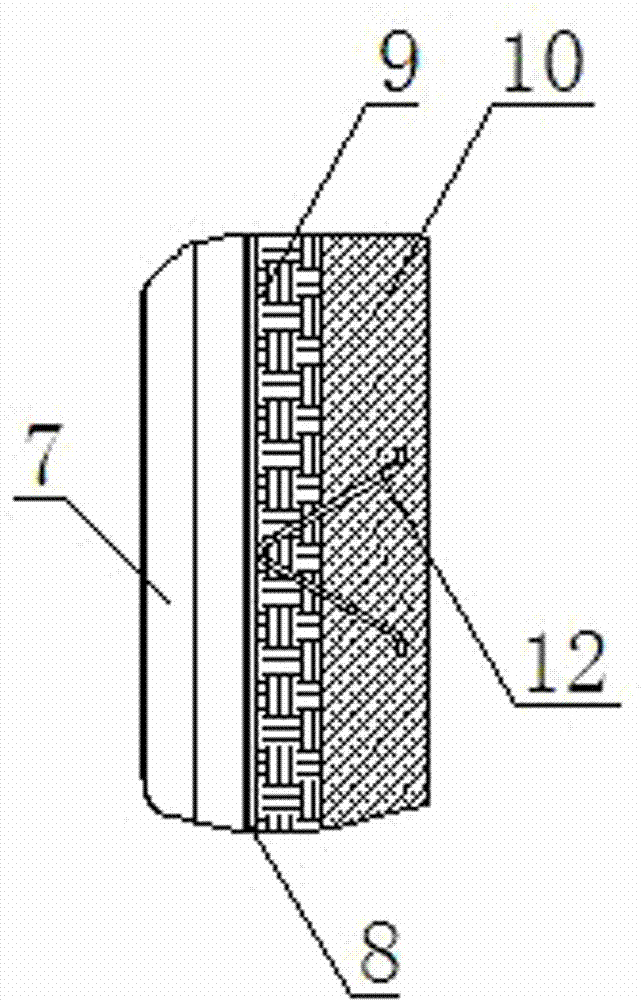

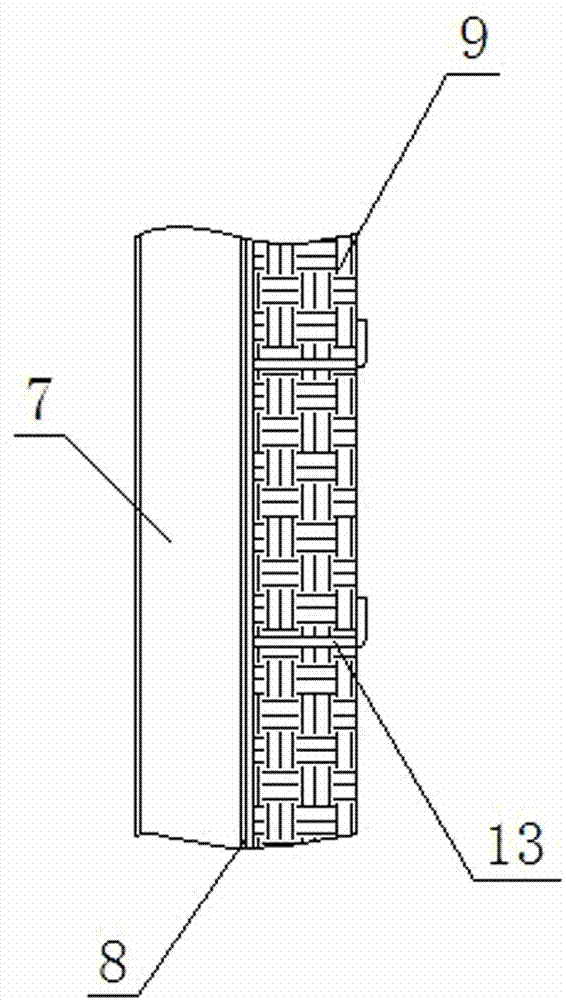

[0016] The light-duty furnace wall of the oil field steam injection boiler is composed of prefabricated furnace wall front wall 1, furnace wall side wall 2, furnace wall top plate 3, furnace wall bottom plate 4 and heat preservation flue 5 installed on the bottom 6 of the sledge. The front wall 1 is composed of section steel 7, outer guard plate 8, heat insulating material 9 and refractory bricks 10 from the outside to the inside. The front wall 1 of the furnace wall is provided with a burner installation port 15 and a manhole door 16; the side wall of the furnace wall 2 The furnace wall top plate 3 and the furnace wall bottom plate 4 are composed of shaped steel 7, outer guard plate 8 and heat insulating material 9 connected in sequence from the outside to the inside; the heat preservation flue is composed of shaped steel, outer guard plate, It is composed of thermal insulation material and inner guard plate.

[0017] The outer guard plate 8 in the front wall of the furnace w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com