Three-section type butt-joint device

A docking device and three-stage technology, which is applied in the direction of drying solid materials, lighting and heating equipment, drying, etc., can solve the problems of waste in pharmaceutical companies, large sterile room space, and non-compliance with GMP requirements, etc., to achieve easy cleaning, The effect of improving production efficiency and easy installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

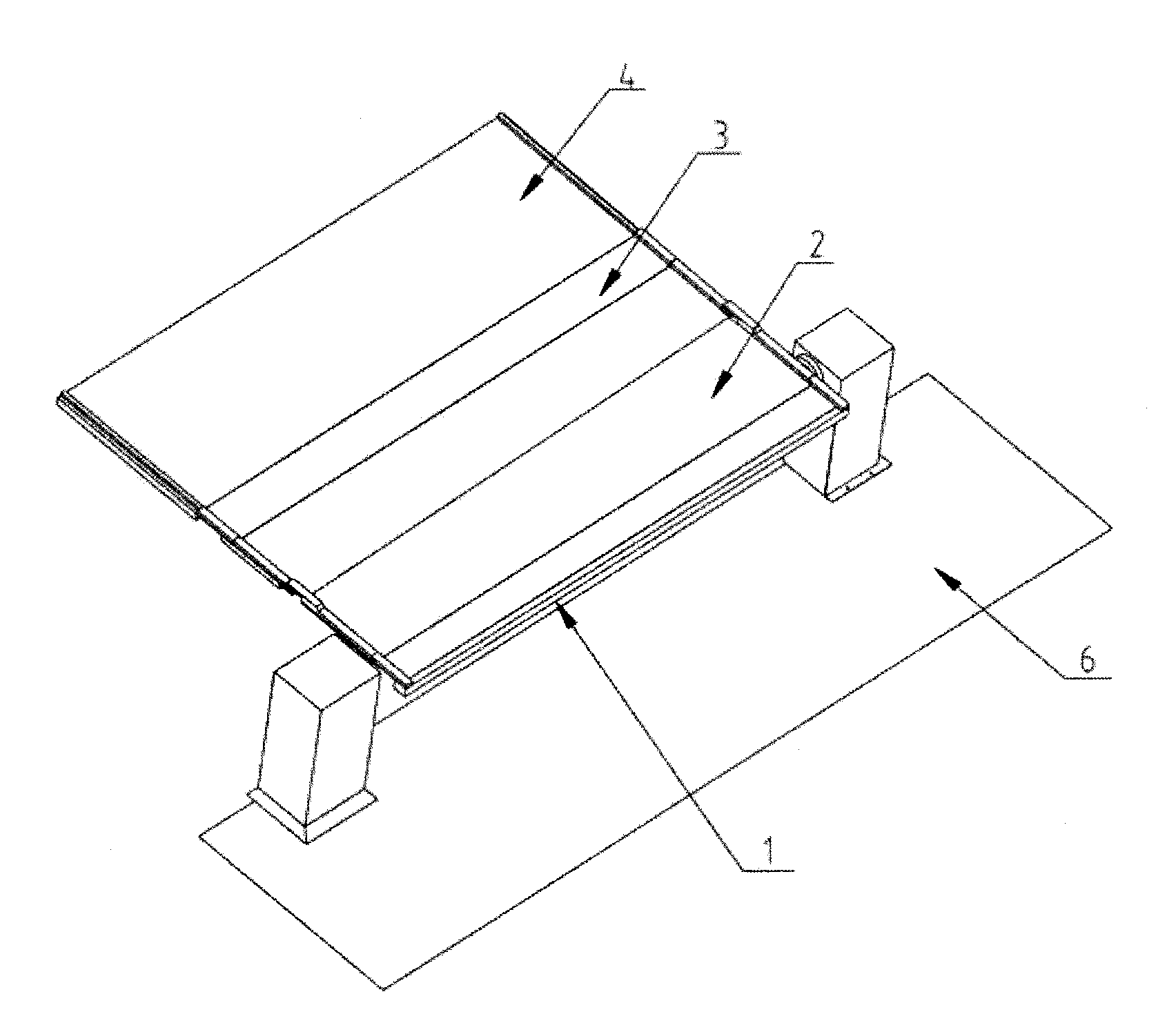

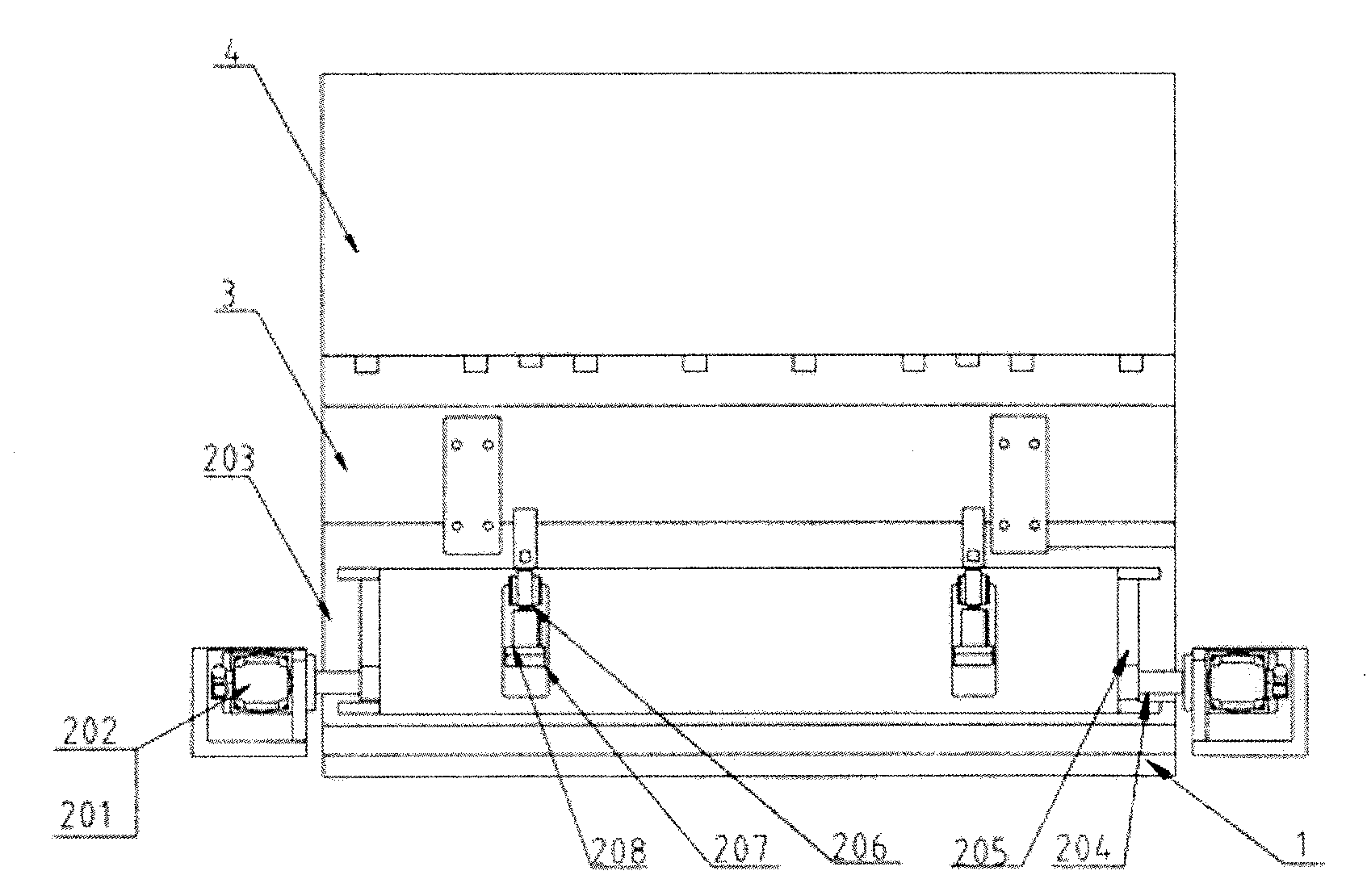

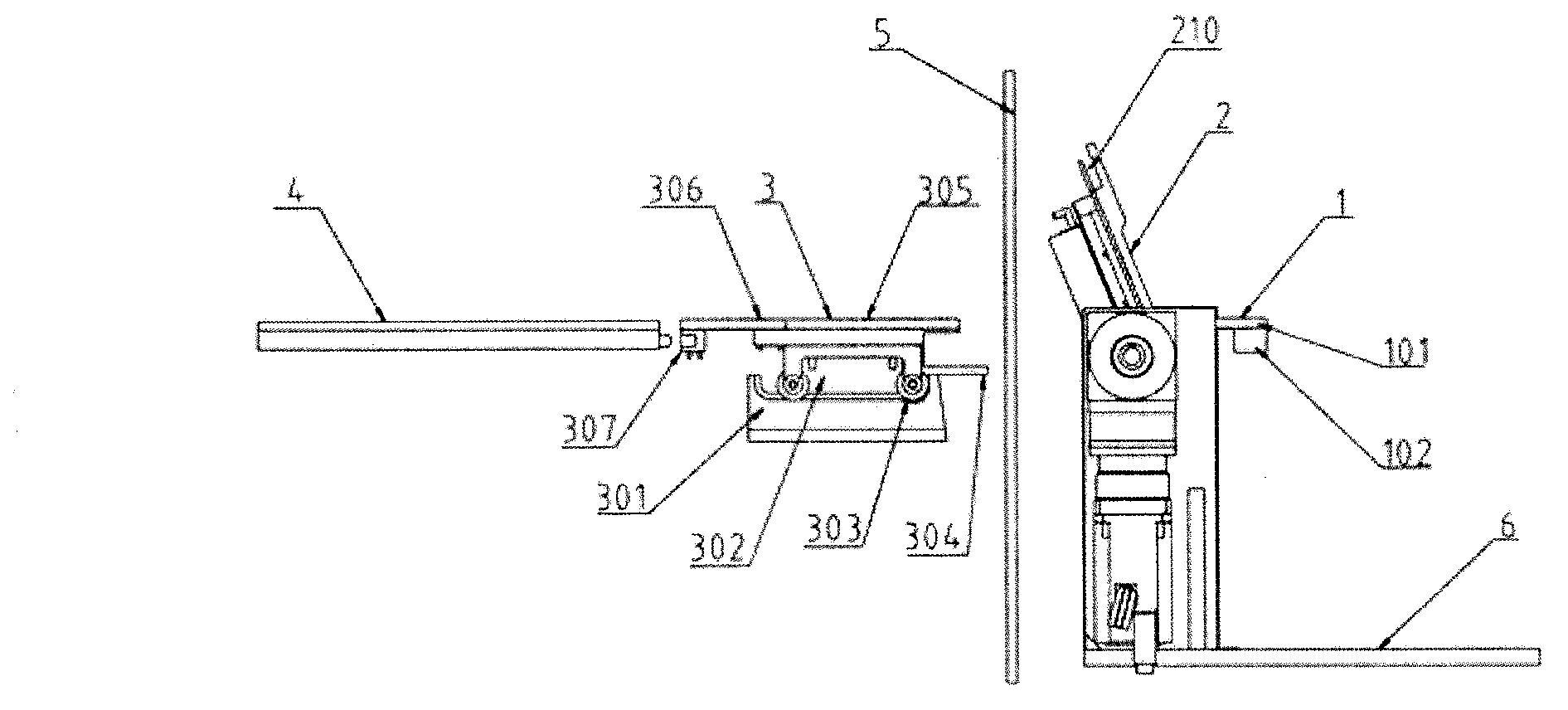

[0026] like Figure 1-5 As shown, it is a structural schematic diagram of the three-stage docking device provided by the present invention, including a base plate 6, on which a docking and turning system 2 is provided, and a docking and fixing system 1 is provided on one side of the docking and turning system 2, and a docking and fixing system 1 is provided on the other side. Docking translation system3. The docking turning system 2 and the docking translation system 3 are respectively installed on both sides of the decorative plate 5 of the freeze dryer. The docking and fixing system 1 includes a fixing plate 101 fixedly connected with the docking and turning system 2 , and a fixing block 102 is provided on the lower side of the fixing plate 101 . The upper side of the docking turning system 2 is provided with a turning plate 203 , and the lower side of the turning plate 203 is evenly equipped with two connecting blocks 205 , and each connecting block 205 is rotationally con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com