A method for determination of a tobacco drying curve

A technology of drying curve and tobacco, which is applied in the directions of measuring devices, measuring instruments, surveying and navigation, etc., can solve the problems affecting the measurement accuracy, unstable operation, large system error, etc., and achieve stable drawing method, good test precision, The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

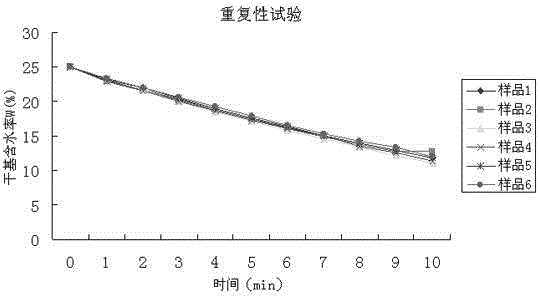

[0014] Embodiment 1 (verify the precision of the method provided by the present invention)

[0015] Taking Xiangxian B2F flue-cured tobacco slices as the experimental object, the wet basis moisture content of the samples at each time was measured with reference to the method provided by the present invention, and the drying curve was drawn.

[0016] 1) Take Xiangxian B2F flue-cured tobacco slices, cut into cut tobacco with a width of 1.0~1.1mm, adjust the moisture content of the sample to 20~26% on a wet basis; take a 10±2g sample, and use the oven method to measure the initial moisture content of the sample W 0湿 .

[0017] 2) Take 6 groups of samples, each group of samples is 10±2g, put them into a flowing hot air oven with an electronic weighing system, continue to dry at 100°C for 10 minutes, and weigh them at intervals during the drying process. 1min, record the sample weight m at time t t .

[0018] 3) After 10 minutes, the equipment will automatically stop, and the dr...

Embodiment 2

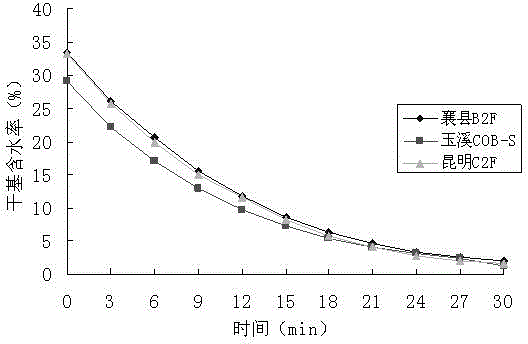

[0022] Determination of tobacco drying curve, comprising the following steps:

[0023] 1) Take Xiangxian B2F, Yuxi COB-S, and Kunming C2F three kinds of flue-cured tobacco slices, cut into shredded tobacco with a width of 1.0~1.1mm, adjust the dry basis moisture content of the sample to 25~35%, and obtain the sample to be tested; each sample Take 10 ± 2g, and use the oven method to measure the initial dry basis moisture content W of the sample 0干 .

[0024] 2) Take 10±2g of each sample, place them in a flowing hot air oven with an electronic weighing system, dry continuously at 90°C for 30 minutes, and weigh them at intervals during the drying process. The weighing interval is 3 minutes, and record Initial sample weight m 0 , sample weight m at time t t .

[0025] 3) The equipment will automatically stop at the end of the set 30 minutes, and the dry basis moisture content W of the sample at time t will be calculated according to the following formula after drying t干 :W t...

Embodiment 3

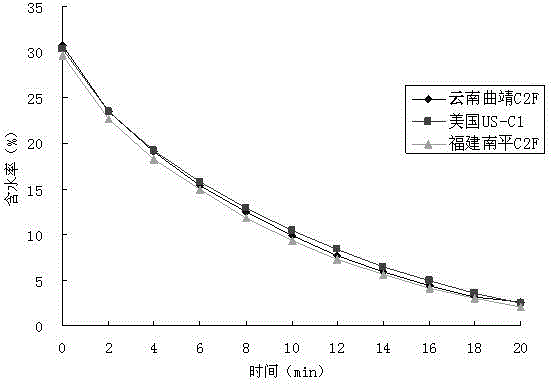

[0030] Determination of tobacco drying curve, comprising the following steps:

[0031] 1) Take Yunnan Qujing C2F, American US-C1, and Fujian Nanping C2F three kinds of flue-cured tobacco slices, cut into shredded tobacco with a width of 1.0~1.1mm, adjust the dry basis moisture content of the sample to 25~35%, and obtain the sample to be tested; Take 10 ± 2g of the sample, and use the oven method to measure the initial dry basis moisture content W of the sample 0干 .

[0032] 2) Take 10±2g of each sample, place them in a flowing hot air oven with an electronic weighing system, and keep drying at 110°C for 20 minutes, and weigh them at intervals during the drying process. The weighing interval is 2 minutes, and record Initial sample weight m 0 , sample weight m at time t t .

[0033] 3) After 20 minutes of drying, the equipment will automatically stop, and then calculate the dry basis moisture content W of the sample at time t according to the following formula t干 :W t干 =m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com