Accelerated degradation test method of knuckle bearing

A technology of accelerated degradation test and joint bearing, applied in the direction of mechanical bearing testing, etc., can solve the problems such as research reports on the accelerated degradation test method of joint bearing that have not been seen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

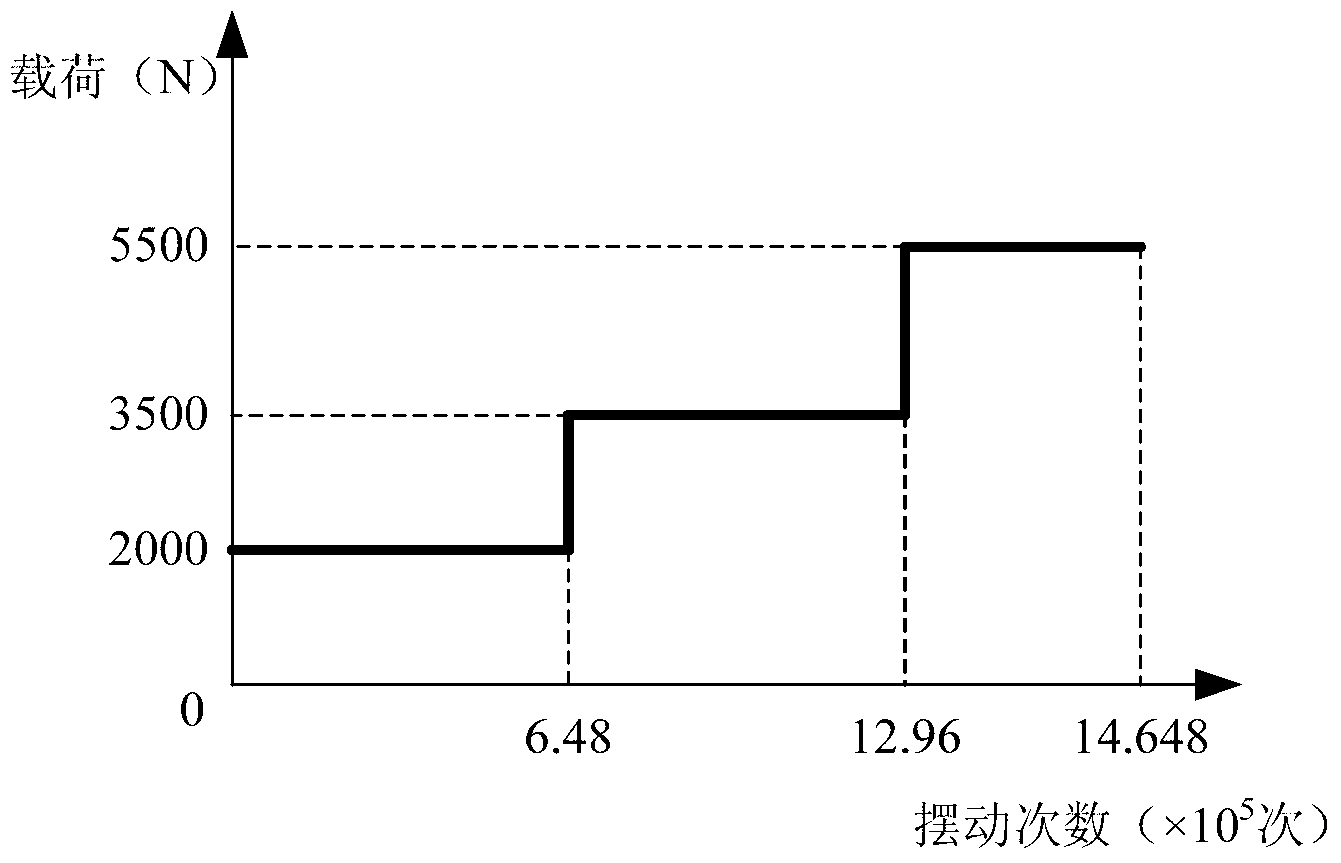

[0050] Example 1 , Joint bearing accelerated degradation test

[0051] Step 1. Set the number of accelerated stress levels h of the load to 3. Due to the limitation of the test time and conditions, the sample size n of the joint bearing is 2, and the samples are respectively marked as M 1 ,M 2 , the two samples were sequentially clamped on a joint bearing swing test bench for testing.

[0052] The load S of the joint bearing in normal use 0 =1000N. The highest level of load obtained through the pre-test is set to 5500N, which can ensure the consistency of the degradation mechanism under normal use conditions. The accelerated stress levels for the given loads are therefore:

[0053] S 1 =2000N, S 2 =3500N, S 3 =5500N.

[0054] Step 2. Install the joint bearing test piece into the tooling, and then install the installed tooling on the main frame of the joint bearing swing test bench, then connect the torsion actuator and the tooling, and then connect and adjust the dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap