Synchronous calibration test method for bridge prestressed automatic tensioning equipment

A test method and prestressing technology, which is applied in the field of synchronous calibration test of bridge prestressed automatic tensioning equipment, can solve the problem of synchronous calibration test of stretching elongation at both ends of the equipment and method, unable to test the synchronous control performance of elongation value, Automatic tensioning equipment can not be put into use and other problems to achieve the effect of avoiding errors, convenient installation and operation, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

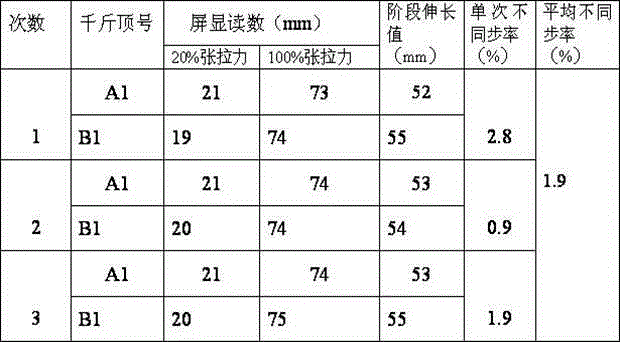

Examples

Embodiment Construction

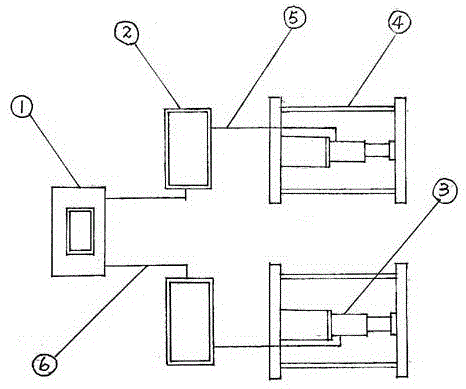

[0025] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0026] Synchronous calibration test method for bridge prestressed automatic tensioning equipment, the steps are as follows:

[0027] Step 1: Place two hydraulic pump stations of automatic tensioning equipment, two jacks to be inspected and one host control cabinet on a flat ground. The placement sequence is the host control cabinet --- two hydraulic pump stations --- two jacks. Then connect the host control cabinet and the two hydraulic pump stations with signal cables, and connect the two hydraulic pump stations and the two jacks with oil pipe signal lines respectively to reach the state of use. The two jacks to be checked are the jacks used at both ends of a bundle of steel strands when the actual bridge is stretched;

[0028] Step 2: Place the frames of the two synchronous calibration test racks horizontally next to the jack, then put the spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com