GMR-MEMS integrated weak magnetic sensor adopting plane micro-coil

A weak magnetic sensor and planar coil technology, applied in the field of weak signal sensing, can solve problems such as restricting the accuracy of the sensor, and achieve the effects of simple structure, reduced nonlinearity and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

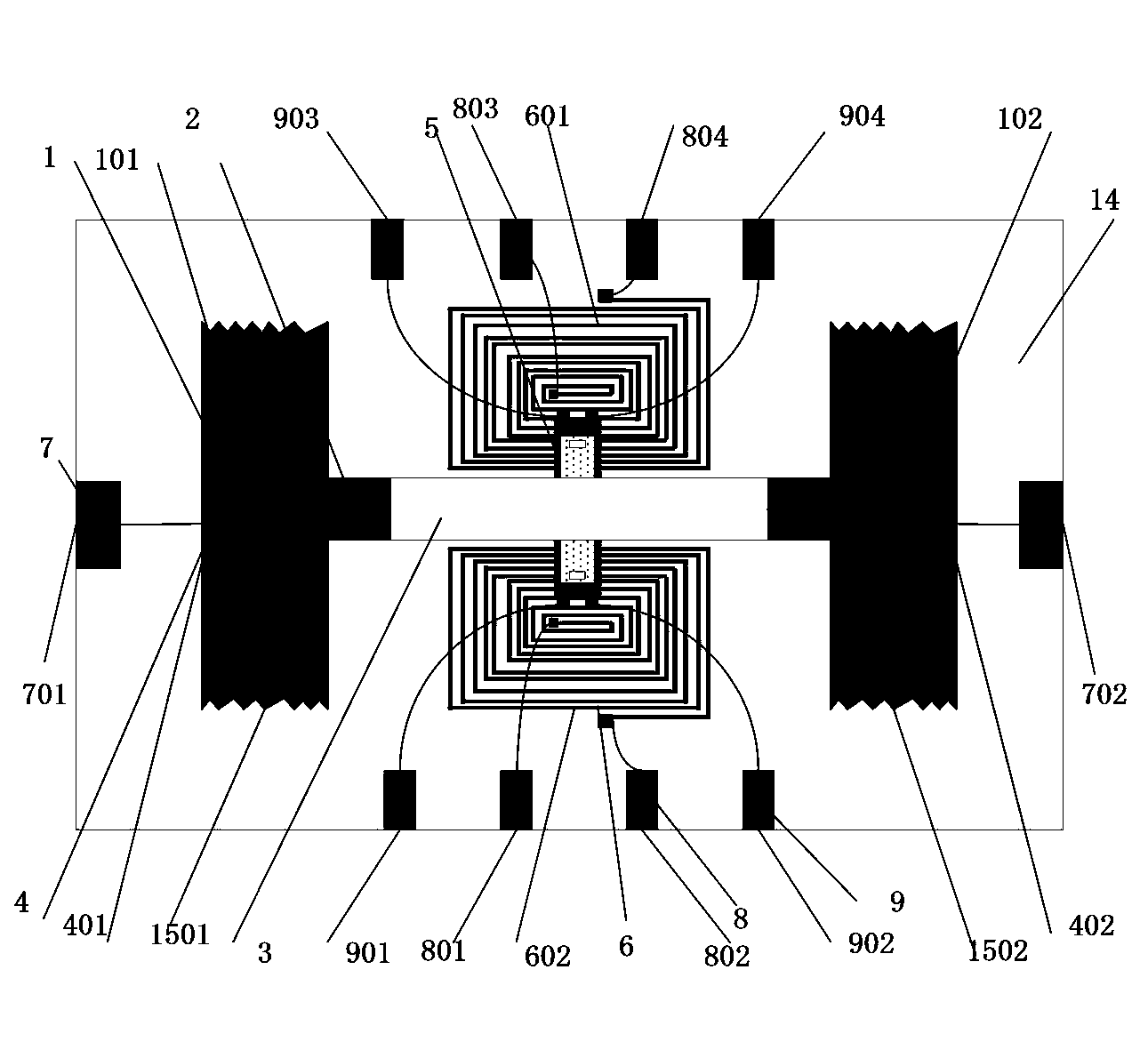

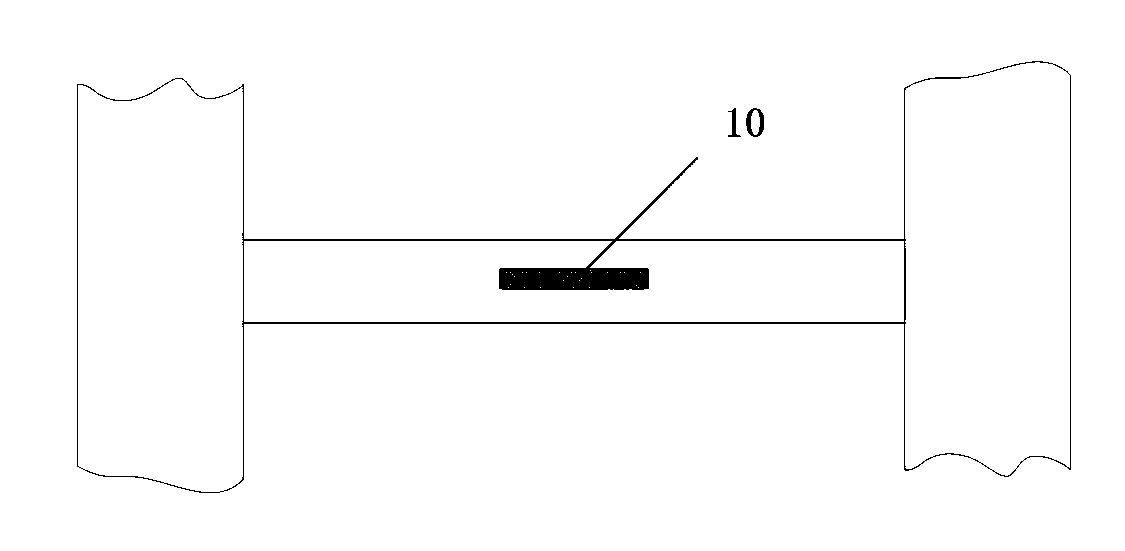

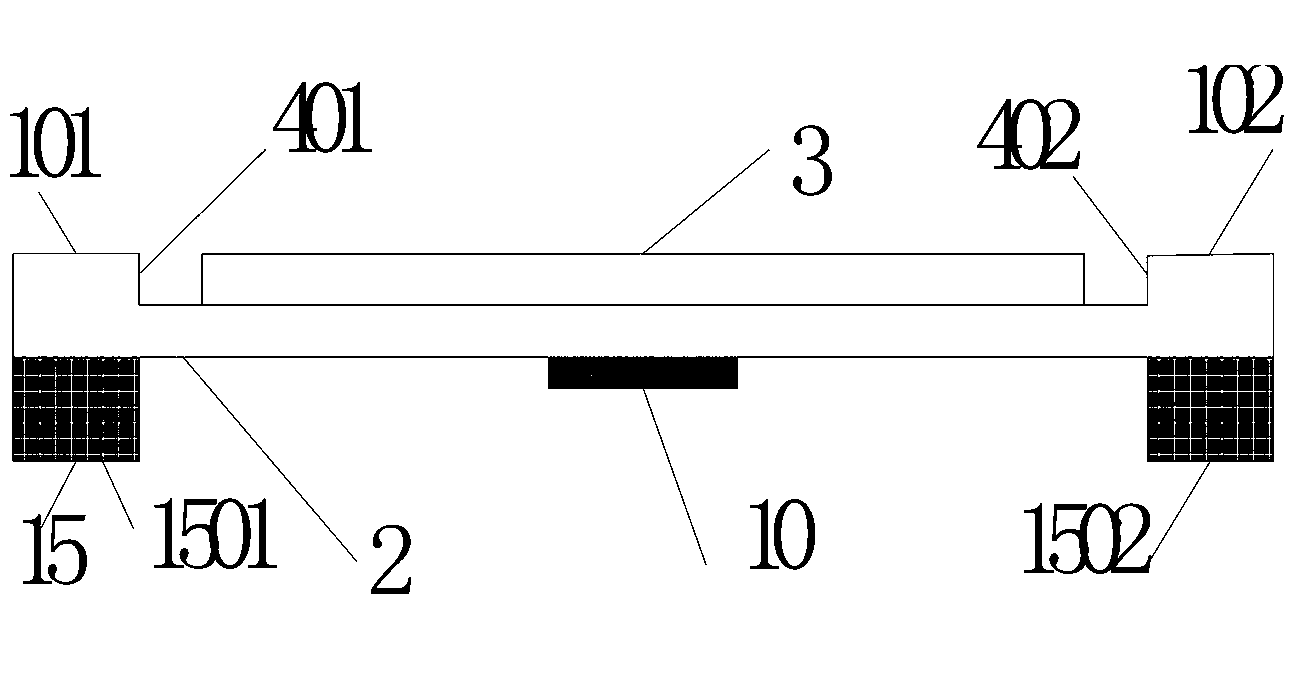

[0022] Such as figure 1 As shown, the GMR-MEMS integrated magnetic field weakening sensor using a planar microcoil of the present invention includes an insulating substrate 14, a gasket 15, a micro piezoelectric bridge, a piezoelectric sheet 3, a GMR sensitive element 5, a planar coil 6, and three sets of electrodes As well as the modulation film 10; the insulating substrate 14 can be made of surface-polished insulating material as required. Three pairs of electrodes are plated on the surface of the insulating substrate 14, and the three groups of electrodes are respectively the piezoelectric sheet driving electrodes 7 (including the first piezoelectric sheet driving electrodes 701 and the second piezoelectric sheet driving electrodes 702 ), the planar coil excitation electrodes 8 ( Including the first planar coil excitation electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com