Measuring transducer driven by monoaxial piezoelectricity for low-intensity magnetic field

A measurement sensor, piezoelectric drive technology, applied in the field of sensors, can solve the problems of low magnetic field resolution, low modulation depth, inconvenient practical use, etc., and achieve the effects of improving measurement resolution, suppressing 1/f noise, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

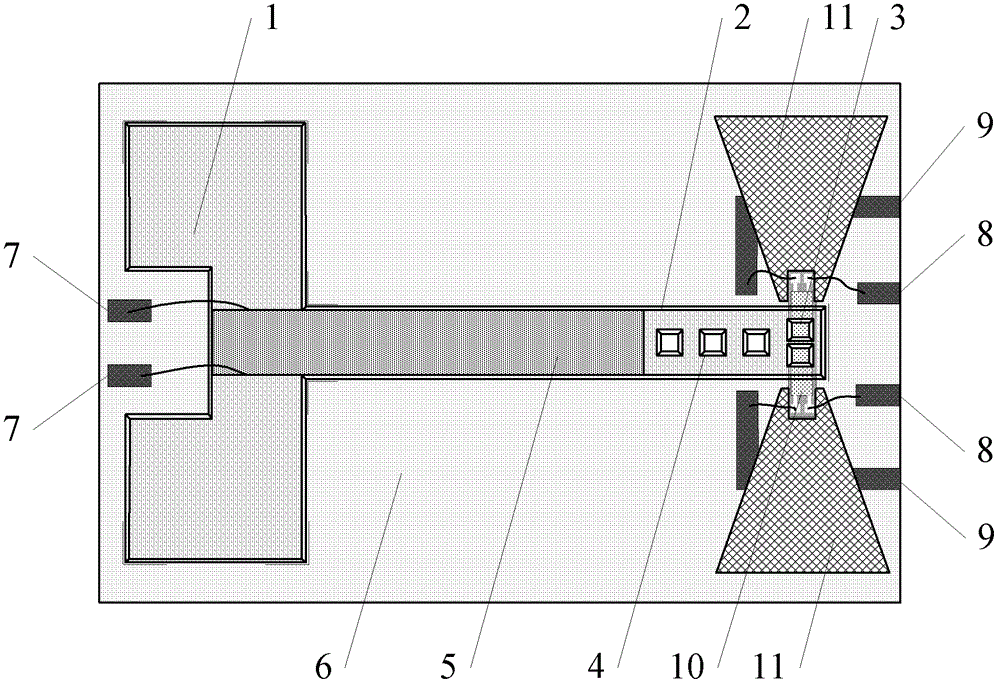

[0016] The present invention will be further described below in conjunction with accompanying drawing.

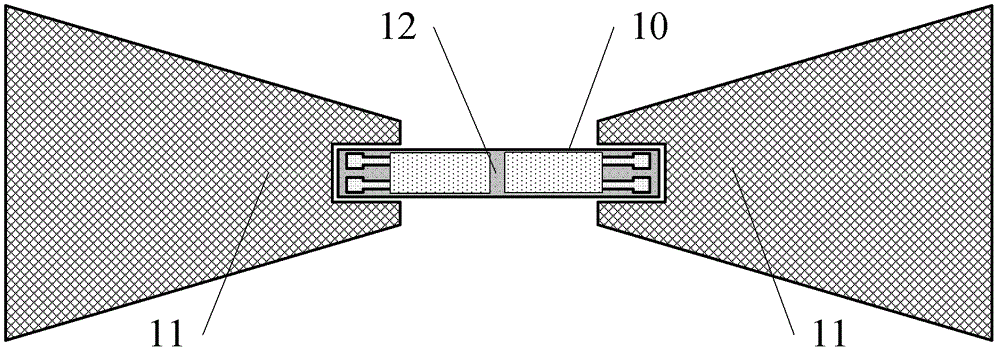

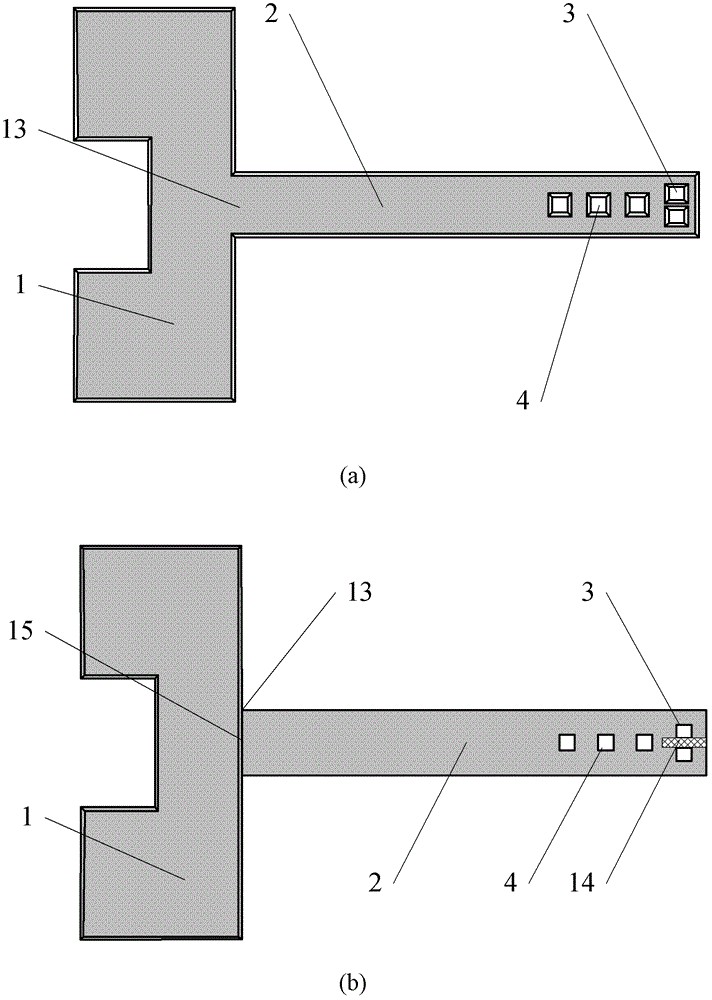

[0017] figure 1 It is a structural schematic diagram of a uniaxial piezoelectric drive weak magnetic field measurement sensor provided by a specific embodiment of the present invention. As shown in the figure: including insulating substrate 6, electrode pair 7, electrode pair 8, electrode pair 9, base 1, cantilever 2, alignment hole 3, damping hole 4, piezoelectric ceramic sheet 5, GMR sensitive element 10 and magnetic field lines Aggregator 11. The insulating base 6 is a glass sheet with a polished surface, and its shape is not limited to the rectangle in this embodiment, but may also be a circle or the like. The electrode pairs 7, 8, 9 are formed by sputtering (or vacuum evaporation, electroplating, etc.) a conductive metal film (gold, aluminum, copper, etc.) on the insulating substrate 6, and then photoetching and etching. The electrode pair 7 is connected to the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com