Image forming apparatus and method of controlling the same

An image and control part technology, which is applied in the direction of electric recording process applying charge pattern, equipment of electric recording process applying charge pattern, electric recording technique, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

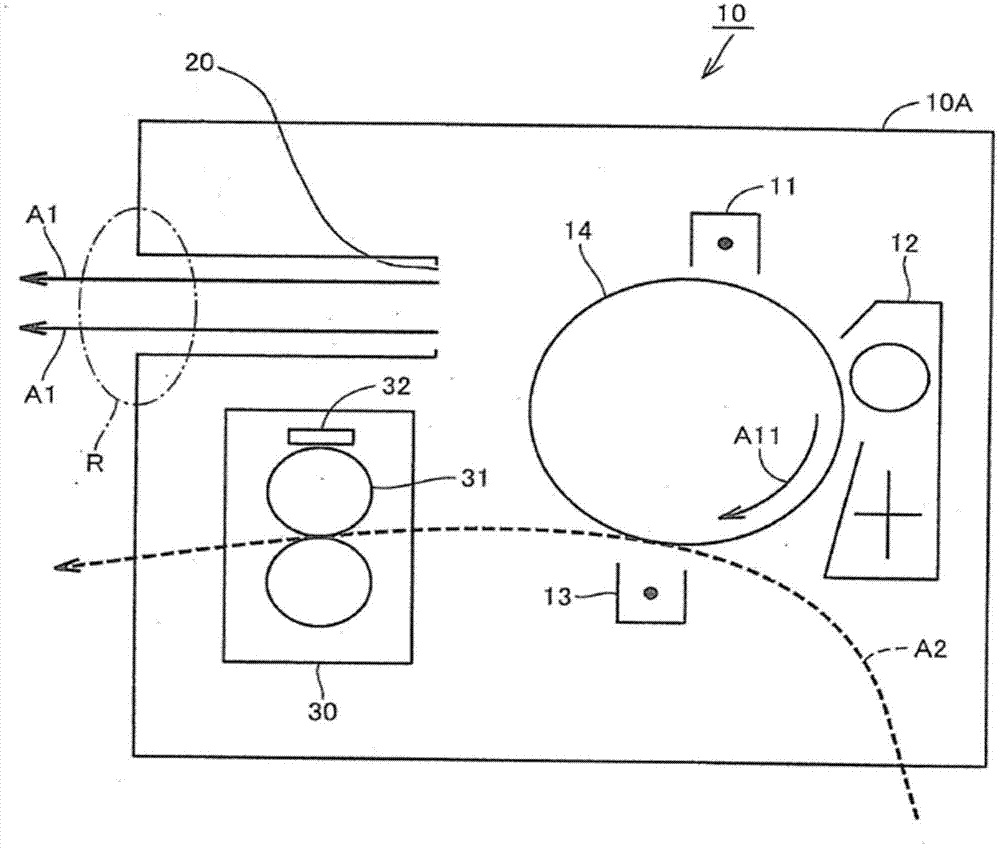

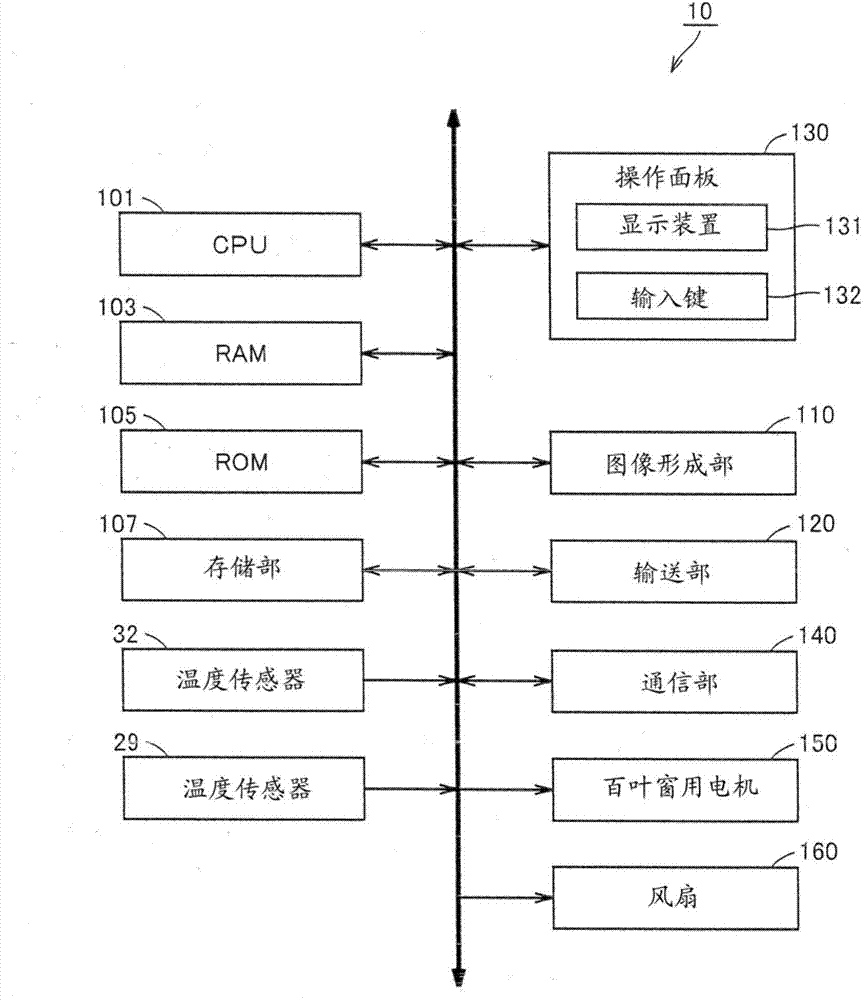

Examples

Deformed example (1

[0068] The printer 10 of the modification (1) may have the same configuration as the above-mentioned printer 10 except for the parts described below. Next, differences between the printer 10 of the modified example (1) and the printer 10 described above will be described.

[0069] in reference to Figure 5 In the opening and closing control of the shutter 21 described above, the shutter 21 is closed when the surface temperature of the fixing roller 31 exceeds 170° C., and the shutter 21 is opened when the temperature of the surface of the fixing roller 31 is 170° C. or lower. In this case, it is conceivable that when the surface temperature of the fixing roller 31 slightly fluctuates around 170° C., the opening and closing states of the shutters 21 are frequently switched.

[0070]In order to avoid such a situation, in the opening and closing control of the louver 21, the louver 21 may be closed when the surface temperature of the fixing roller 31 exceeds a first temperature,...

Deformed example (2

[0073] The printer 10 of the modification (2) may have the same configuration as the above-mentioned printer 10 except for the parts described below. Next, differences between the printer 10 of the modification (2) and the printer 10 described above will be described.

[0074] In the printer 10, when the temperature of the fixing roller 31 rises, the air outlet 20 is closed. In order to suppress the temperature rise in the casing 10A caused by such control, the printer 10 may further include a fan different from the fan 160 .

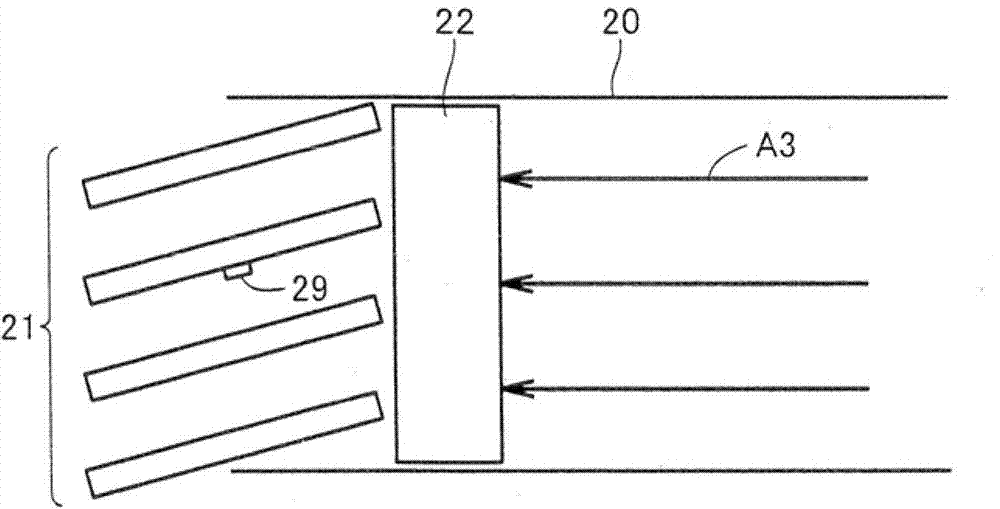

[0075] Figure 7 It is a figure for demonstrating the cooling method of the housing|casing 10A by the fan different from the fan 160. Figure 8 It is a diagram showing the hardware configuration of the printer 10 according to the modification (2).

[0076] refer to Figure 7 , in the modified example (2), the external fan 23 provided separately cools the louver 21 provided in the exhaust port 20 from the outside of the housing 10A. When the louver ...

Deformed example (3

[0079] The printer 10 of the modification (3) may have the same configuration as the above-mentioned printer 10 except for the parts described below. Next, differences between the printer 10 of the modification (3) and the printer 10 described above will be described.

[0080] In modification (3), in the opening and closing control of the louver 21 , when a specific condition is satisfied, the louver 21 is opened even if the surface temperature of the fixing roller 31 exceeds 170° C.

[0081] The specific condition in the modified example (3) is that the temperature near the air outlet 20 (hereinafter also referred to as the temperature near the opening of the housing 10A) exceeds a specific temperature. That is, in the modified example (3), when the temperature near the exhaust port 20 exceeds a specific temperature, even if the surface temperature of the fixing roller 31 exceeds 170° C., the louver 21 is opened.

[0082] Figure 9 It is a flowchart of the opening and closi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com