Electronic equipment with photosensitive function, flexible printed circuit board and socket

A technology for flexible circuit boards and electronic equipment, applied in the field of electronics, can solve the problems of occupying motherboard space, increasing the weight and cost of electronic equipment, and difficulty in motherboard wiring design, so as to save design space and save material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

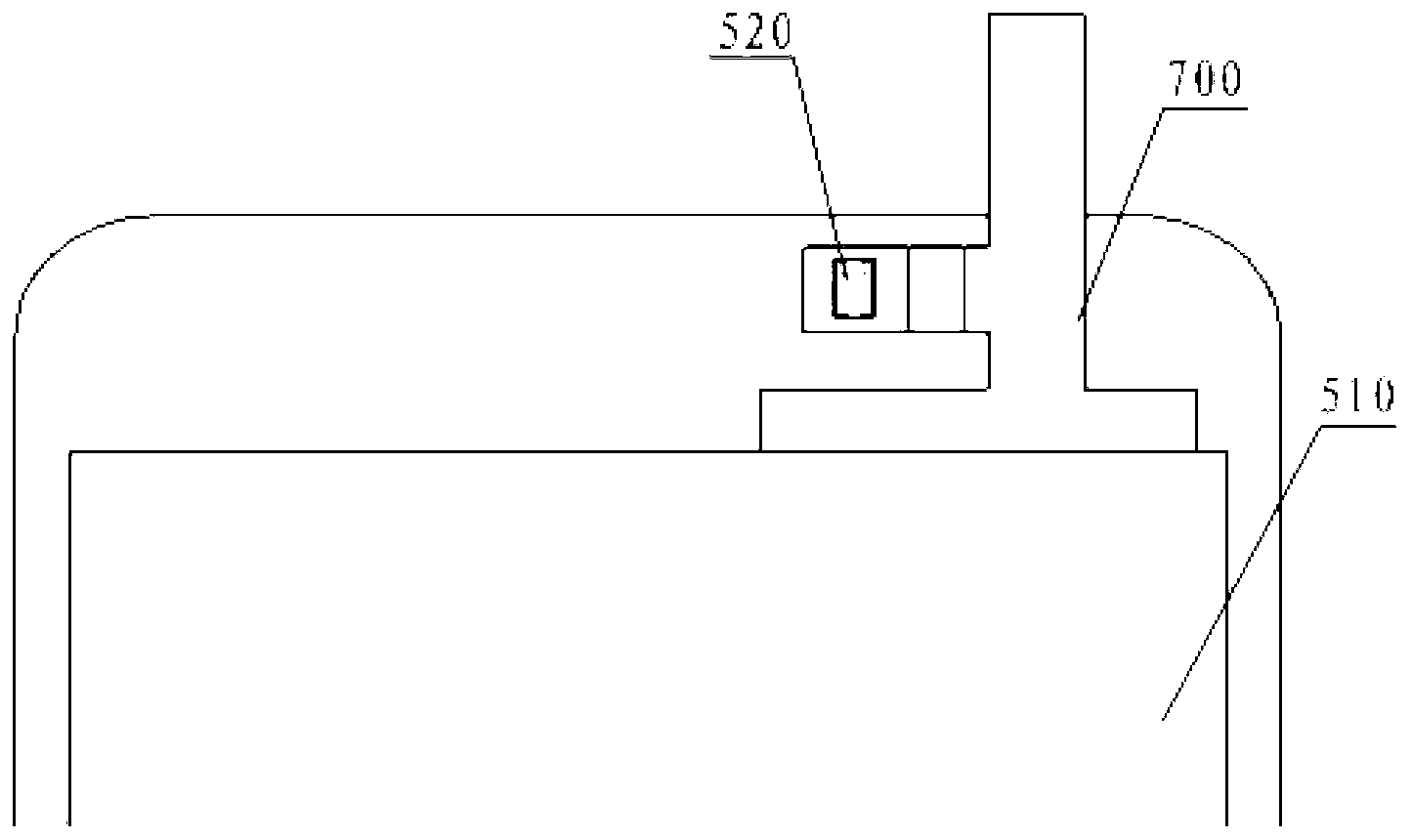

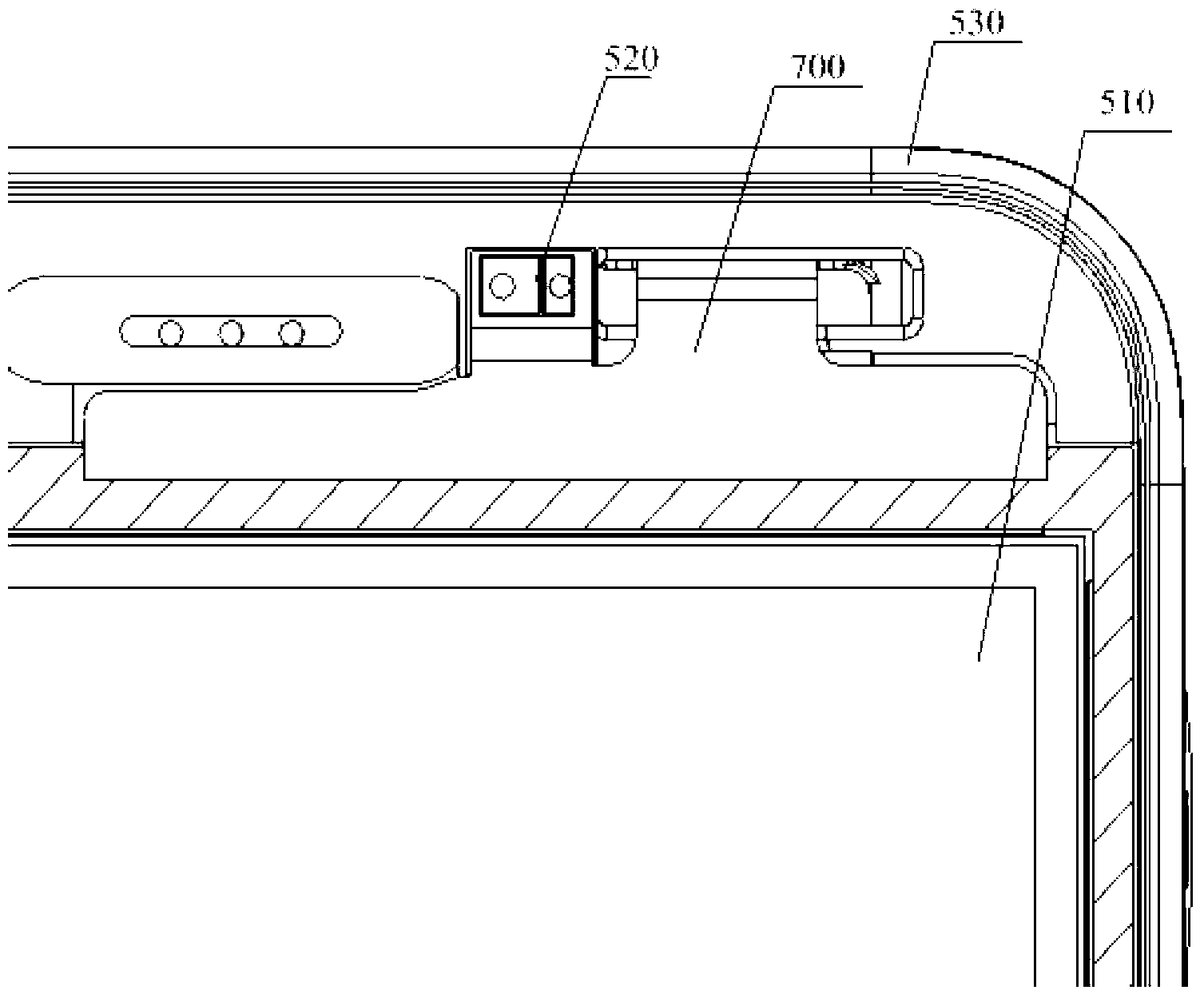

[0018] Such as figure 2 As shown, the electronic device with photosensitive function includes a light sensor 520 and an upper casing 530 . Those skilled in the art can understand that the upper casing 530 is usually the side on which the display screen 510 is provided.

[0019] Such as Figure 5 As shown, in the electronic device with photosensitive function provided by this embodiment, the upper casing 530 is composed of a transparent surface layer 531 and a non-transparent printing layer 532; the non-transparent printing layer 532 has a first through hole 511 and a second through hole 521 , so that the upper casing 530 is a transparent structure at the positions of the first through hole 511 and the second through hole 521; the display screen 510 of the electronic device is arranged at a position corresponding to the first through hole 511, so that the user can The display content of the display screen 510 can be viewed at the position of a through hole 511; the light sens...

Embodiment 2

[0023] The electronic device with photosensitive function provided in Embodiment 2, like Embodiment 1, also includes a light sensor 520 and an upper casing 530. Those skilled in the art can understand that the upper casing 530 is usually provided with a display screen 510. one side.

[0024] Such as Figure 6 As shown, the upper casing 530 is made of a non-transparent layer 631 made of a non-transparent material; the upper casing 530 has a first through hole 511 and a second through hole 521; the display screen 510 of the electronic device is arranged on the first through hole 511, so that the user can watch the display content of the display screen 510 through the position of the first through hole 511; the light sensor 520 has a light receiving part, and the light sensor 520 is pasted on the inner wall of the upper casing 530 and its receiving part It is located at a position corresponding to the second through hole 521 , so that the light sensor 520 can sense ambient light...

Embodiment 3

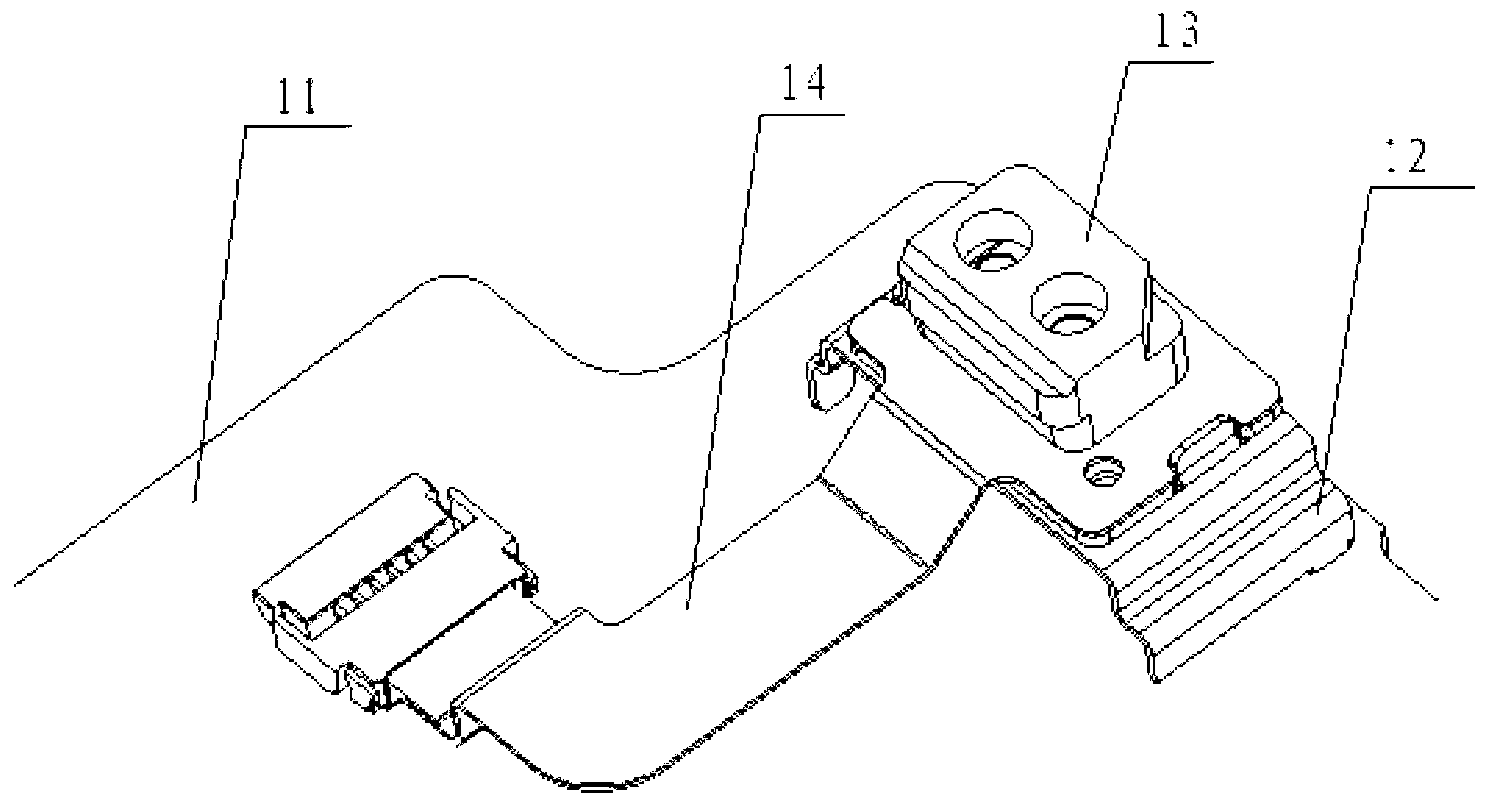

[0030] This embodiment provides a schematic structural diagram of a flexible printed circuit board 700 (Flexible Printed Circuit Board). The flexible printed circuit board 700 (Flexible Printed Circuit Board) is equipped with a display signal circuit and an induction signal circuit. The display signal circuit includes a plurality of mutually insulated The wire; the induction signal circuit also includes a plurality of mutually insulated wires; the display signal circuit and the induction signal circuit are also insulated from each other.

[0031] Such as Figure 7 As shown, the flexible printed circuit board 700 (Flexible Printed Circuit Board) is Y-shaped with three connection ends, the three connection ends are respectively the first connection end 710, the second connection end 720 and the integrated connection end 730; the three connection ends Each is provided with a number of line terminals, wherein the number of line terminals on the centralized connection end is the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com