Expanding device for combining a liquid species and a particulate solid species

A contact device, a technology for solid particles, used in transportation and packaging, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve problems such as energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

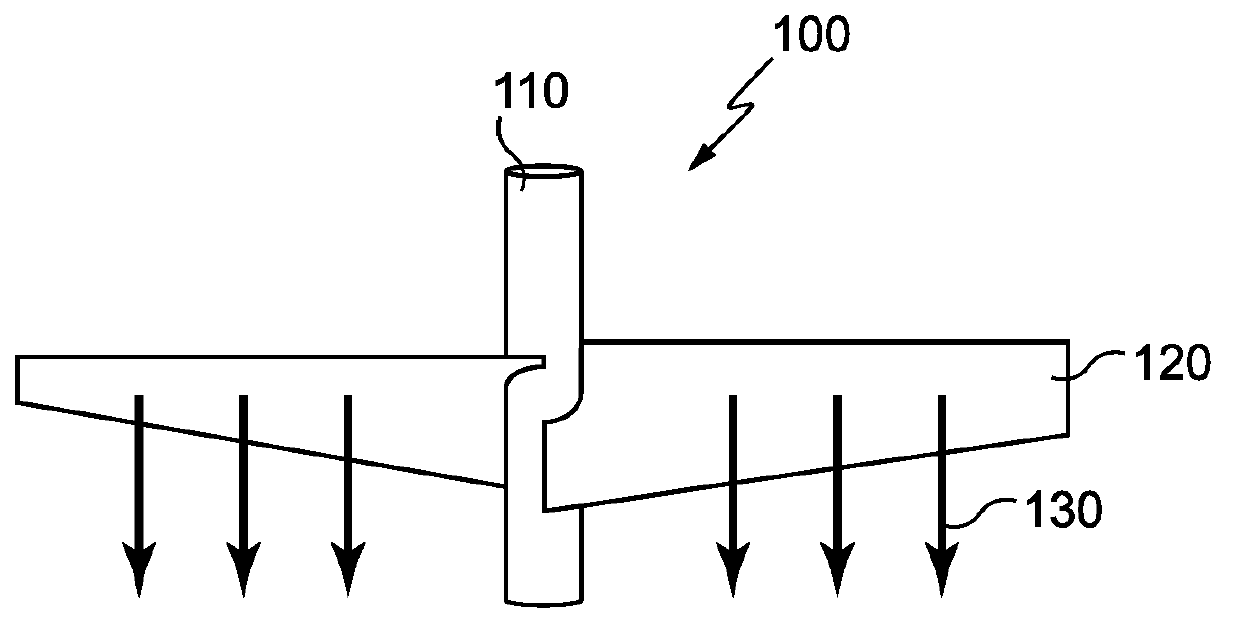

[0051] exist figure 1 Above, an agitator 100 is shown, which may typically be used in a contacting tank for contacting a liquid species with a solid species. The stirrer comprises: a shaft 110 about which the stirrer is given rotational motion (for example due to the action of a motor not shown); and blades 120 which are generally regularly distributed around the shaft 110 and which are generally identical for all The shape and arrangement of the blades allows the rotating agitator to apply an axial thrust 130 (also defined as longitudinal thrust) to the liquid in which the agitator is immersed. The number of blades of the agitator 100 is at least two, but the more blades the agitator includes, the better the performance of the device.

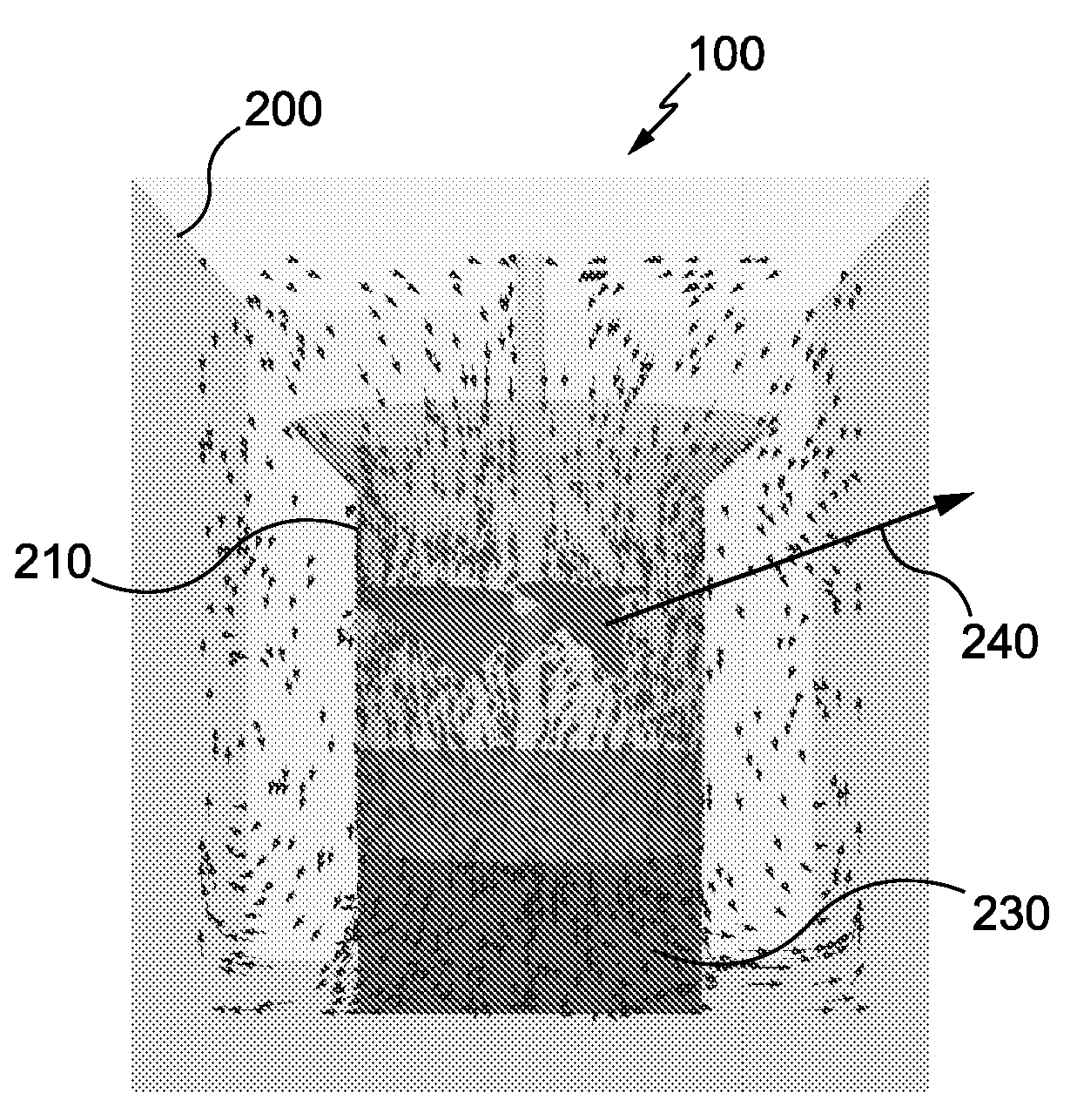

[0052] Typically, such agitators may be arranged in a draft tube, a device consisting essentially of a cylinder, usually with a circular lower base, hollow, separating the inner and outer areas, pushed axially by 130 The propelling fluid flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com