Process and system for manufacturing composite material products, as well as products manufactured with this process or system

A composite material and process technology, applied in the field of shell and roof production technology, can solve the problems of limited service life of molds, achieve the effects of reducing equipment costs, reducing the number of molds, and ensuring repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

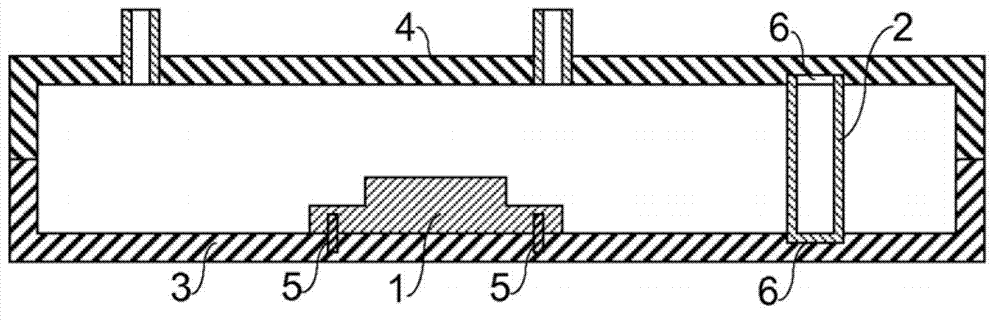

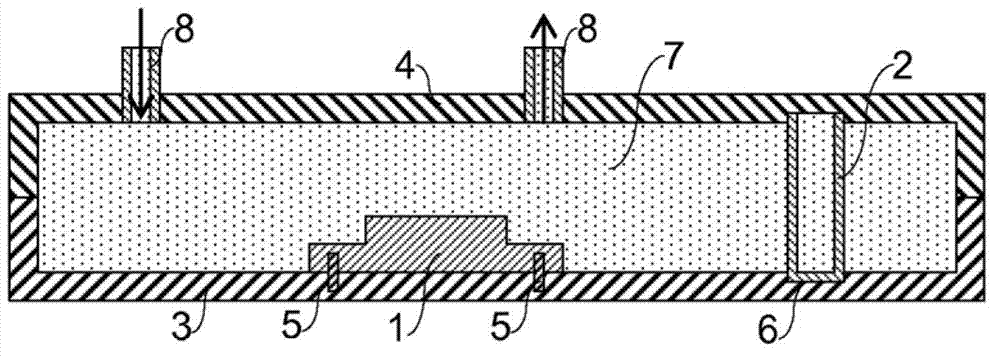

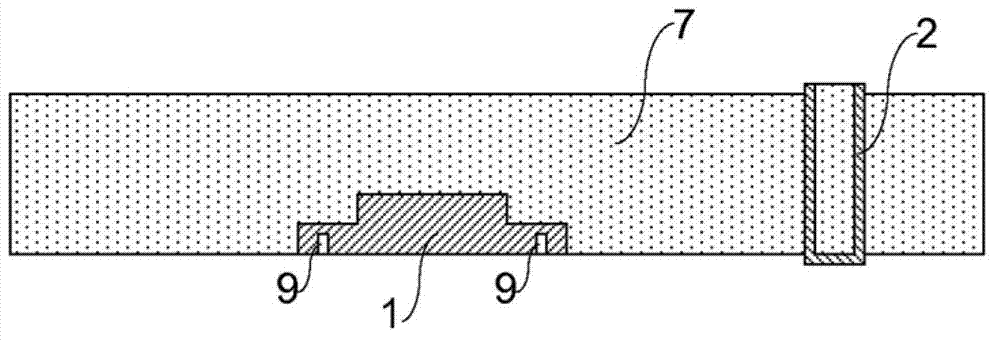

[0040] see figure 1, as can be seen from the figure, in the first step of the process, one or more first inserts 1, 2 are arranged in one or more auxiliary molds 3, 4 and are connected to at least one functional surface of these molds touch. The first insert 1, 2 is preferably made of metal composite material, especially a composite material of aluminum or light alloy and carbon fiber, or a combination of these materials, between two or more fiber linings in a preparatory step , for metal insert molding, the auxiliary molds 3 and 4 are preferably made of composite materials, especially carbon fiber. The auxiliary molds 3 and / or 4 are preferably equipped with a protruding body 5 and / or a base 6 to keep the first inserts 1, 2 in a designated position. For this purpose, the shape of the first inserts 1 , 2 is adapted to the above-mentioned convex body 5 and / or base 6 . Typically, the protruding body 5 is a pin, which is inserted into the corresponding hole of the first insert ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com