Infrared-reflecting substrate

An infrared and substrate technology, applied in the direction of reflection/signal coatings, coatings, instruments, etc., can solve the problem of low transparency and achieve the effects of high transparency, excellent infrared reflection performance, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

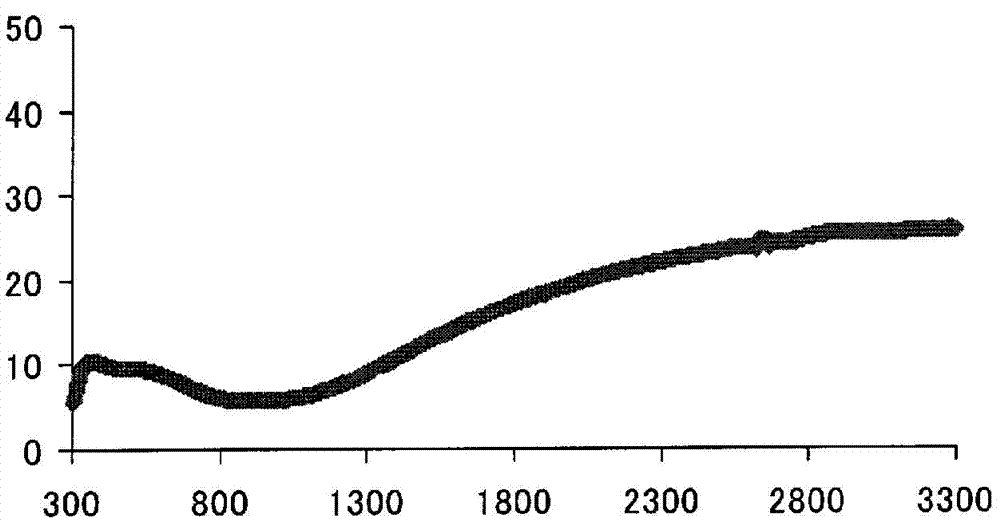

[0093] (Example 1) Example of using plate glass:

[0094] 50.0 g of an aqueous dispersion of a composite of poly(3,4-ethylenedioxythiophene) and polystyrenesulfonic acid (manufactured by Heraeus Co., Ltd.: CleviosP, conductivity 0.09 S / cm, solid content 1.3%), 0.5 g of surfactant (solids 10%), 0.05 g of leveling agent (solids 100%), 2 g of water, and 8 g of ethanol were mixed and stirred for 30 minutes. The resulting mixture was filtered through a 400-mesh SUS-made sieve to prepare a coating agent.

[0095] The obtained coating agent was coated on a blue plate glass (manufactured by advanced materials technology Co., Ltd.: AMT-8292) with a thickness of 0.7 mm by the bar coating method using a wire bar No. 8 (wet film thickness 18 μm), and Dry at 100° C. for 1 minute to obtain a base.

Embodiment 2)

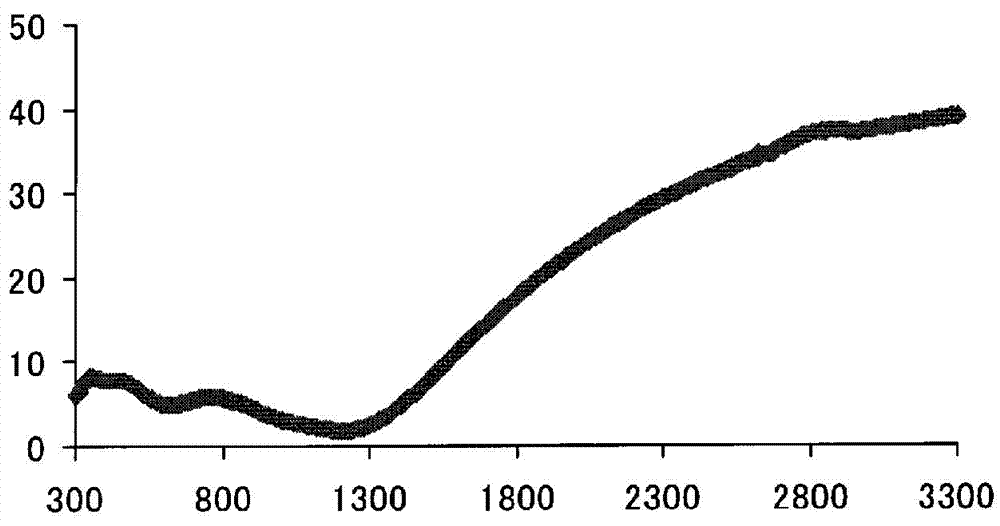

[0096] (Example 2) Example of using plate glass:

[0097] Instead of CleviosP in Example 1, Clevios P HC V4 (manufactured by Heraeus Co., Ltd.: conductivity 0.23 S / cm, solid content 1.2%), the matrix was obtained by the same method as in Example 1.

Embodiment 3)

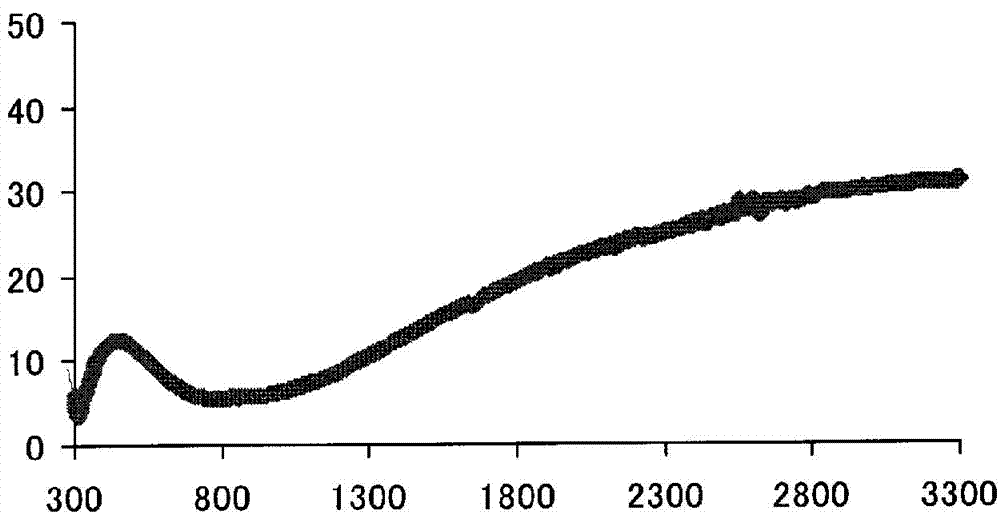

[0098] (Example 3) Example of using plate glass:

[0099] Instead of CleviosP in Example 1, Clevios PH1000 (manufactured by Heraeus Co., Ltd.: conductivity 0.46 S / cm, solid content 1.1%), the matrix was obtained by the same method as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com