Two-dimensional automatic dust collection device based on spiral track

A technology of automatic dust removal and driving device, which is applied to household heating, space heating and ventilation details, heating methods, etc., and can solve the problems of ineffective cleaning of the filter screen, poor dust blowing effect, and large volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

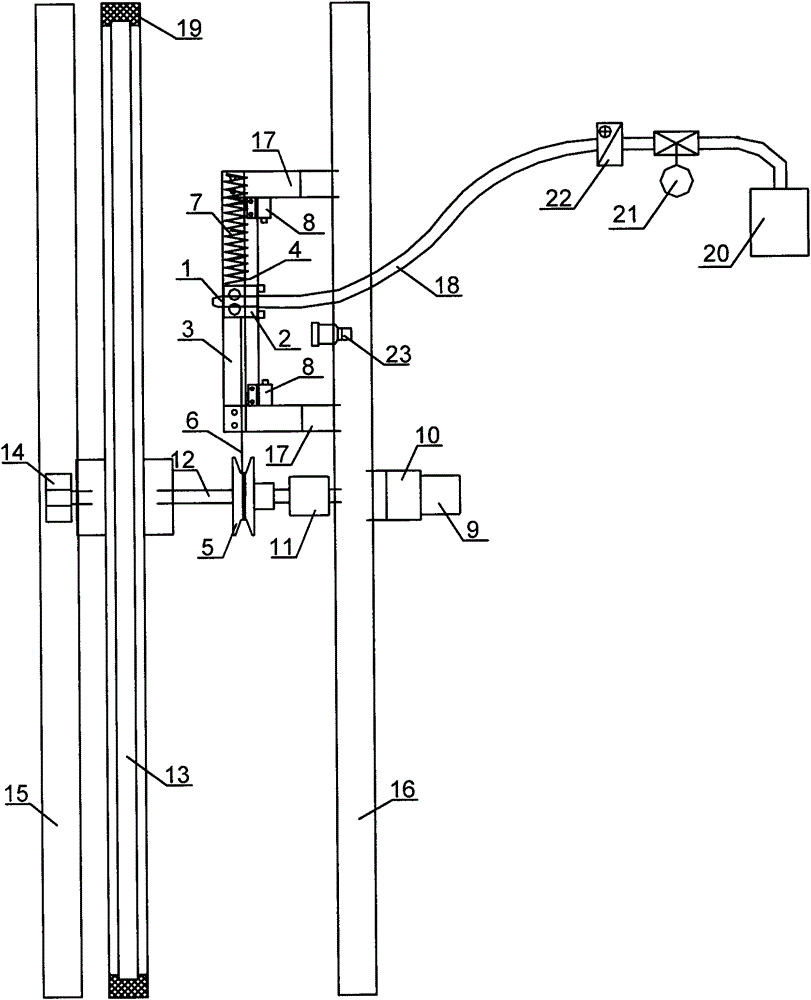

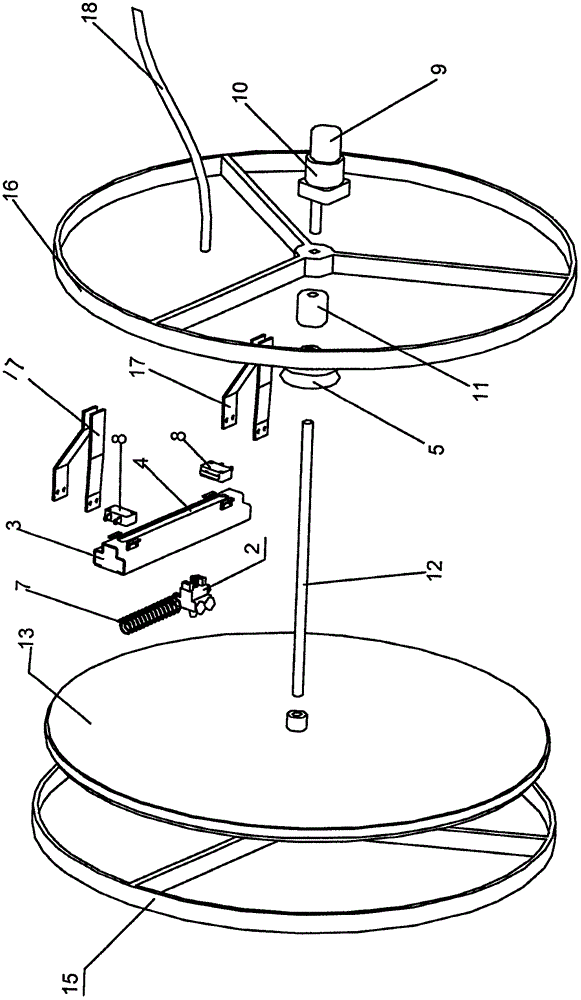

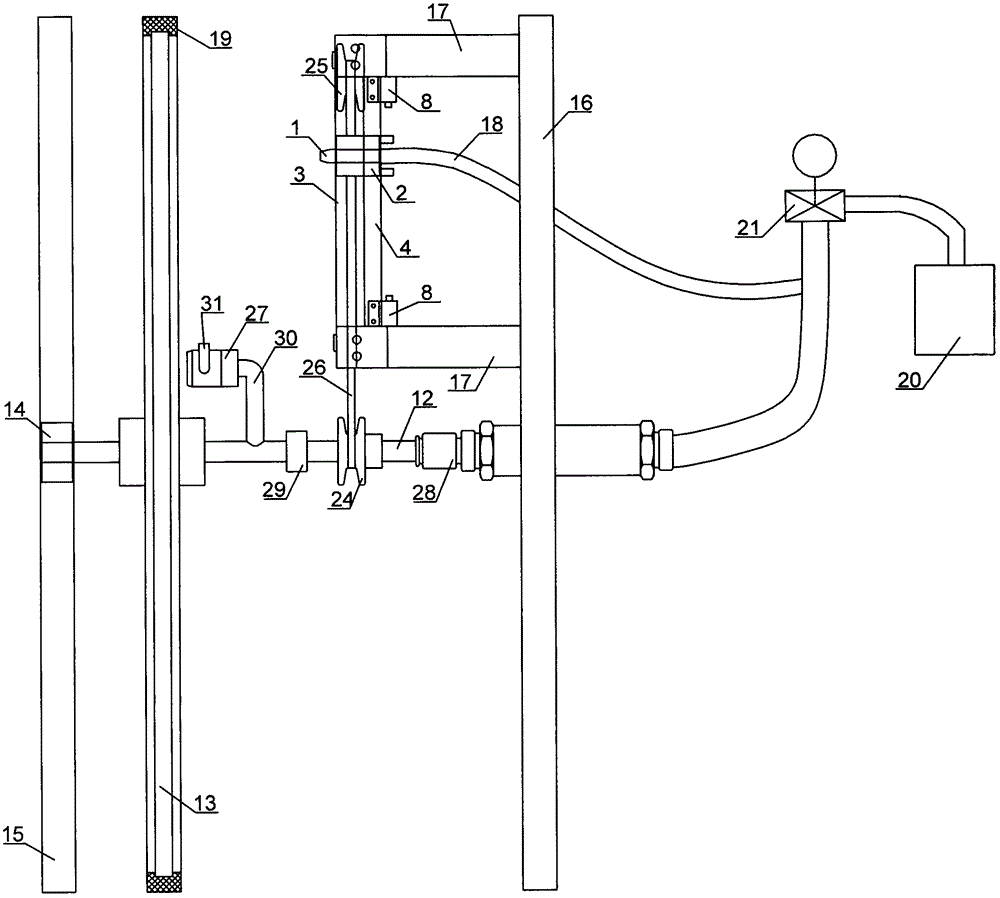

[0030] The following with attached Figure 1 to Figure 5 The two-dimensional automatic dust removal device based on the spiral trajectory of the present invention will be further described in detail.

[0031] For the two-dimensional automatic dust removal device based on the spiral trajectory of the present invention, please refer to Figure 1 to Figure 5 , including a frame body and a driving device installed on the frame body, a dust removal head 1, a rotating device, a sliding device, a traction device and a gas device, and the rotating device includes a rotating shaft 12 and a central sleeve fixed on the rotating shaft The filter screen 13 on 12, the dust removal head 1 includes an air inlet and an air injection port, the air injection port faces the filter screen 13, the air inlet is connected with the gas device to supply air, and the sliding device includes Carriage 3, the chute 4 arranged on the chute 3 and the slider 2 sliding in the chute 4, the front part of the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com