Automatic transceiving and polishing device for electrode cap

A technology of automatic sending and receiving, electrode cap, applied in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of material waste welding cost, human resource waste, labor waste, etc., to reduce welding cost and improve work efficiency , the effect of eliminating the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

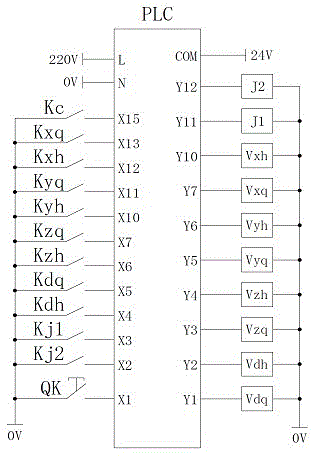

[0017] The invention organically combines a PLC electric control system with an air control system and a mechanical system, and realizes the automatic control of the sending and receiving of the electrode cap and the grinding process.

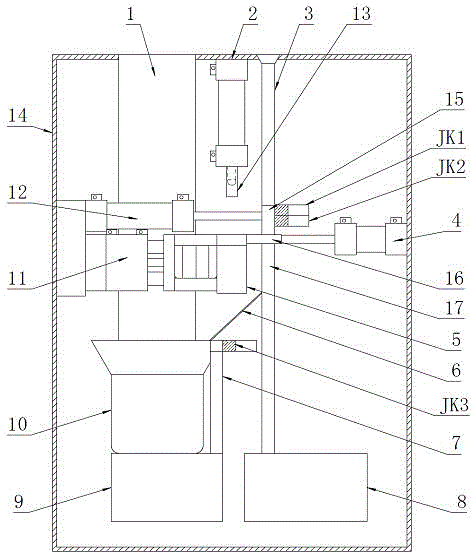

[0018] see figure 1 , the present invention includes a cabinet 14, an old parts classification device, a grinding device, a distribution device and a control system, wherein the old parts classification device includes an old parts inlet pipe 3, a baffle cylinder 4, a transfer cylinder 12, a transfer pipe 15, and a horizontal baffle 16 and waste conveying pipe 17; Grinding device comprises compression cylinder 2, grinder 5, grinder cylinder 11 and capping sleeve 13; Dispensing device comprises new parts inlet pipe 1, deflector 6, new parts conveying pipe 7. New parts container 9 and vibration conveyor 10 .

[0019] see figure 2 , the control system of the present invention comprises PLC, starting switch QK, the first advance piece proximity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com