Manufacturing method of glass fiber reinforced plastic base plate for coating mechanical performance testing

A production method and glass fiber reinforced plastic technology are applied in the field of the production of glass fiber reinforced plastic bottom plates, which can solve the problems of low single-sided roughness of the bottom plate, unreasonable process design, poor wettability of pouring glue, etc., achieving convenient and fast preparation process, excellent other properties, and improved wettability. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

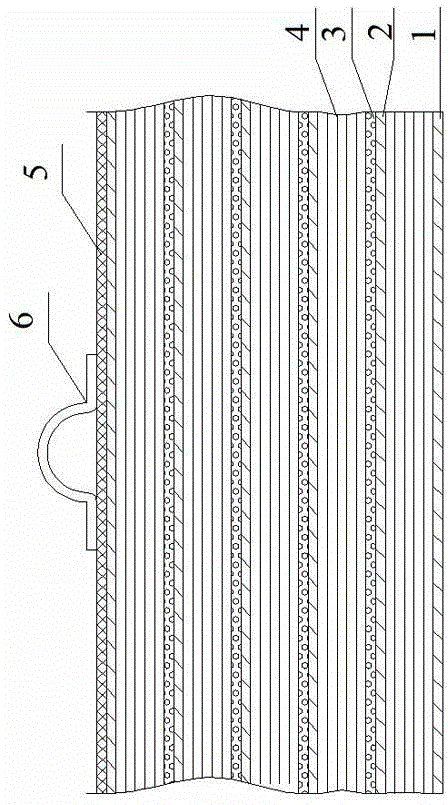

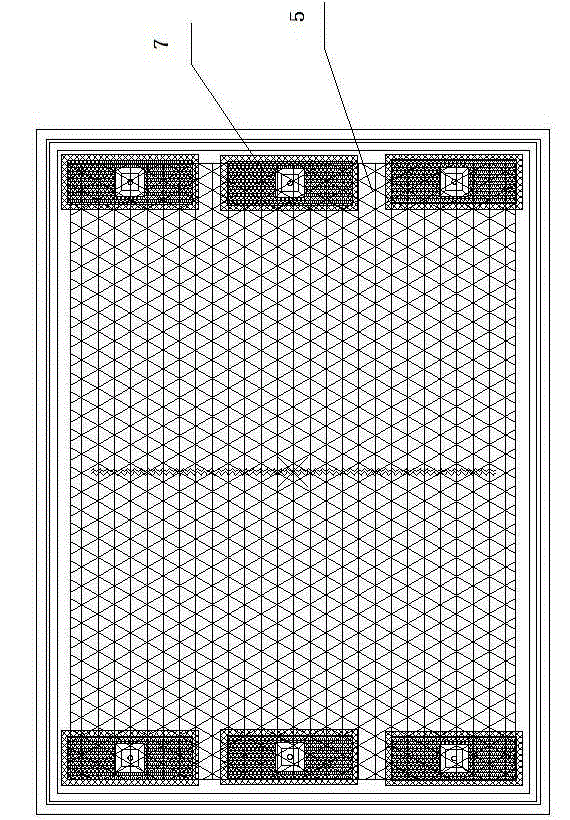

[0021] Example 1, reference Figure 1-2 , A manufacturing method of FRP bottom plate for testing mechanical properties of coatings. The operating area is the surface of the glass workbench mold. The operating steps are as follows:

[0022] (1) Clean the surface of the glass workbench mold;

[0023] (2) Put two sealant strips on the operating area, the first is 2cm away from the mold flange, and the second is 3-4cm apart;

[0024] (3) Wrap the wax with a soft towel to wipe in a circular spiral shape. After the whole wax is applied, at an interval of 3 minutes, break it with a clean soft towel before the wax is completely dried until there is no residual solid wax, and then wipe it to the mold The surface is shiny; under the premise of ensuring that the previous wax is completely crisp, complete the waxing once every 2-3h, and waxing 2 times in total;

[0025] (4) Lay 6 layers of biaxial fiberglass cloth layer by layer according to the size of the mold surface. The laying needs to be f...

Embodiment 2

[0028] Example 2, reference Figure 1-2 , A manufacturing method of FRP bottom plate for testing mechanical properties of coatings. The operating area is the surface of the glass workbench mold. The operating steps are as follows:

[0029] (1) Clean the surface of the glass workbench mold;

[0030] (2) Put two sealant strips on the operating area, the first is 2cm away from the mold flange, and the second is 3-4cm apart;

[0031] (3) Wrap the wax with a soft towel to wipe in a circular spiral shape. After the whole wax is applied, at an interval of 3 minutes, break it with a clean soft towel before the wax is completely dried until there is no residual solid wax, and then wipe it to the mold The surface is shiny; under the premise that the previous wax is completely and completely crisp, the whole waxing is completed once every 2-3 hours, and the waxing is 2 times in total;

[0032] (4) Lay 6 layers of biaxial fiberglass cloth layer by layer according to the size of the mold surface....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com