Concrete strutting piece and preparation technology thereof

A preparation technology and support technology, which is applied in the direction of building components, building reinforcements, structural elements, etc., can solve the problems of contact surface cracking, volume expansion, and uneven distance, and achieve the effect of accelerated processing speed and large friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

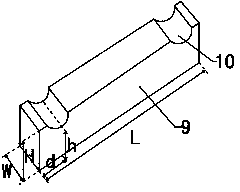

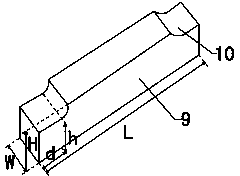

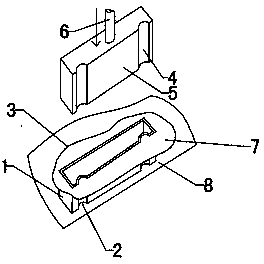

[0031] Embodiment 1 is the best embodiment of the used mold of construction technique of the present invention, below in conjunction with attached Figure 1~3 And embodiment the present invention is described further.

[0032] Example 1

[0033] 1) According to the weight of 42.5 parts of ordinary Portland cement, 100 parts, stone chips 510 parts, and water 54 parts, the concrete support is made. Among them, the stone chips are crushed by a stone crusher, sieved and matched until the mass percentage of the particles is: D≤0.1cm stone chips account for 37%, 0.1cm<D≤0.2cm stone chips account for 28%, 0.2cm<D≤0.3 The stone chips of cm accounted for 20%, and the stone chips of 0.3cm<D≤0.5cm accounted for 15%. The weight ratio of stone chips to water is 1:0.105. The manufactured support body is similar to a thin strip-shaped cuboid structure, and a steel bar groove is respectively opened on the left and right sides of the upper surface of the pad body. The length of the support ...

Embodiment 2

[0039] 1) According to the ingredients of 42.5 parts by weight, 100 parts of ordinary Portland cement, 480 parts of stone chips, and 48 parts of water, make a concrete support with the length of the support body L140mm, the width W20mm of the support body, and the height H20mm of the support body. The shape of the support body is the same as in Embodiment 1. Among them, the stone chips are crushed by a stone crusher, sieved and matched until the mass percentage of the particles is D≤0.1cm stone chips account for 30%, 0.1cm<D≤0.2cm stone chips account for 30%, 0.2cm<D≤0.3cm The stone chips accounted for 26%, and the stone chips with 0.3cm<D≤0.5cm accounted for 14%. The weight ratio of stone chips to water is 1:0.1.

[0040] 2) Refer to attached figure 2 Design and prepare the mold for the concrete support, 72 lower molds 1 are arranged on the same mold frame plate 7, the opening surface of the upper mold opening 3 is equal to the plane where the mold frame plate 7 is located...

Embodiment 3

[0045] 1) According to the ingredients of 42.5 parts by weight, 100 parts of ordinary Portland cement, 520 parts of stone chips, and 55 parts of water, make a concrete support with the length of the support body L250mm, the width W30mm of the support body, and the height H30mm of the support body. The shape of the support body is the same as in Embodiment 1. Among them, the stone chips are crushed by a stone crusher, sieved and matched until the mass percentage of the particles is: D≤0.1cm stone chips account for 30%, 0.1cm<D≤0.2cm stone chips account for 31%, 0.2cm<D≤0.3 The stone chips of cm accounted for 25%, and the stone chips of 0.3cm<D≤0.5cm accounted for 14%. The weight ratio of stone chips to water is 1:0.106.

[0046] 2) Refer to attached figure 1 , 3 Design and prepare the mold for the concrete support, 38 lower molds 1 are arranged on the same mold frame plate 7, the opening surface of the upper mold opening 3 is equal to the plane where the mold frame plate 7 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com