Support frame

A support frame and support part technology, applied in the field of support frames, can solve problems such as space occupation and easy breakage of positioning devices, and achieve the effect of strong support structure, simple structure and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

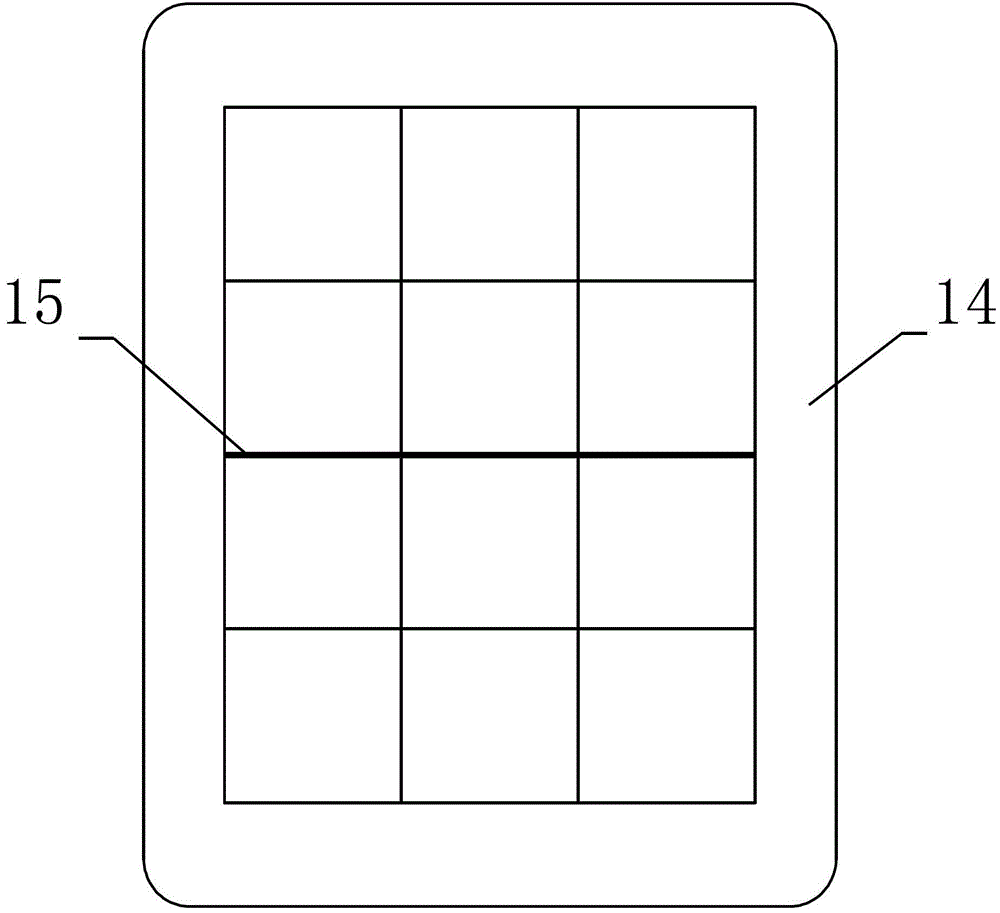

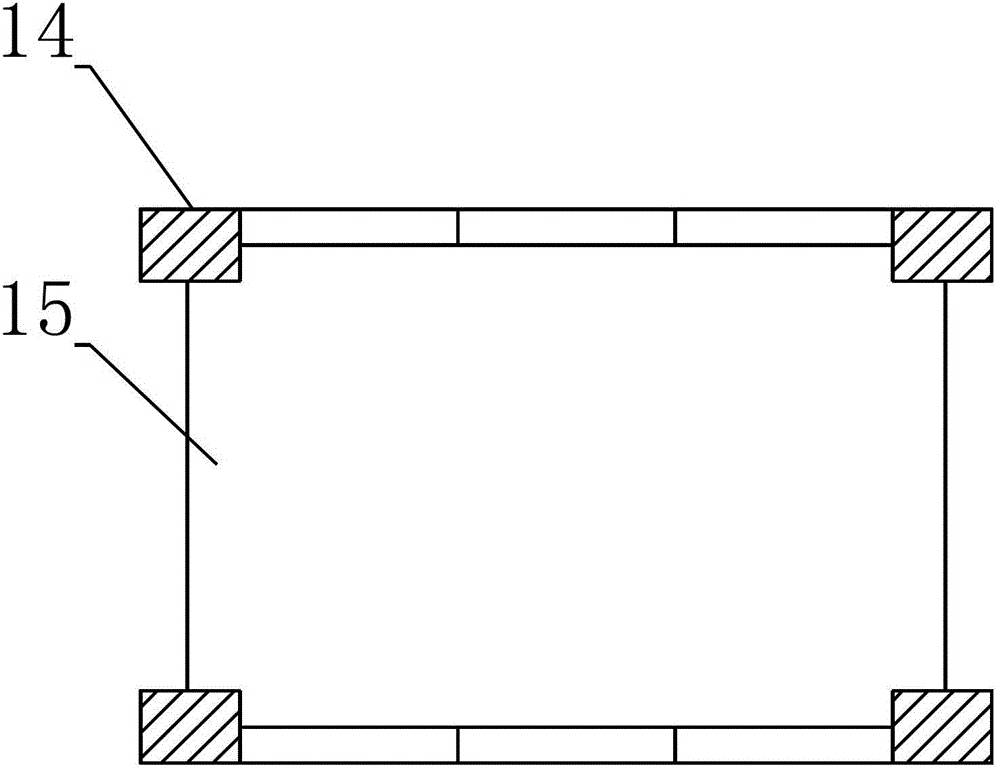

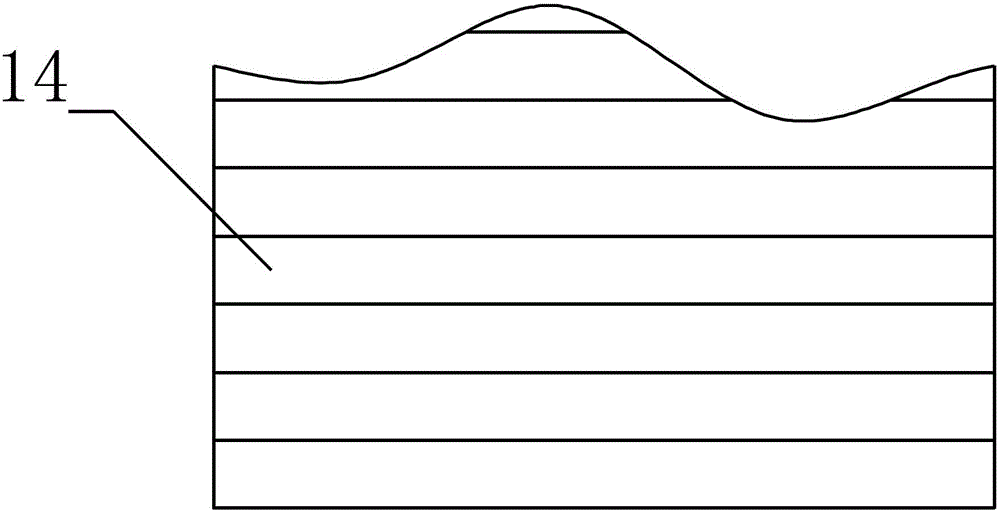

[0030] The first embodiment of the present invention, such as Figure 4 , 5As shown, the support frame includes an upper support frame 1, and the upper support frame 1 is formed by die-cutting corrugated cardboard. Corrugated cardboard is formed by bonding face paper and wavy core paper interlayers. The wavy core paper interlayers are continuously bent to form grooves 3, and the directions between adjacent grooves 3 are opposite and the extension directions are parallel. After die-cutting and forming, the body of the upper support frame 1 is provided with a positioning part I4, a wrapping part I5 and a supporting part I6. Both the wrapping part I5 and the supporting part I6 are integrally connected with the positioning part I4, and the wrapping part I5 and the positioning part I4 are demarcated and distinguished by the crease line 7 . The positioning part I4 is a rectangular structure, the length of the long side is greater than the length of the wide side, and the extending...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com