Shock absorption and noise reduction curved pipe pressure balancing type expansion joint

A balanced and expansion joint technology, applied in the field of expansion joints, can solve problems such as system turbulence, potential safety hazards in pipeline system operation, excessive pressure drop, etc., and achieve the goal of reducing system vibration and noise, obvious vibration reduction effect, and reduced force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

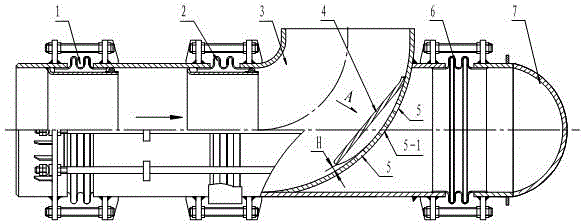

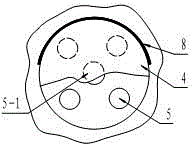

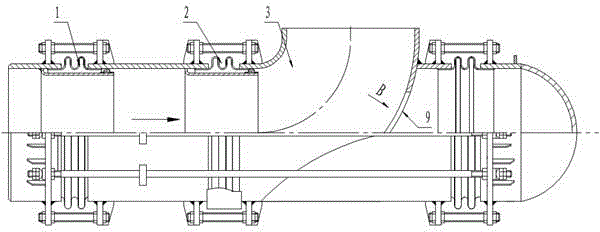

[0017] see figure 1 , figure 2 , The present invention is a curved pipe pressure balance type expansion joint, the expansion joint is used in the pipeline system to absorb the combined axial and lateral displacement, and can balance the pressure thrust of the bellows. The expansion joint includes an elbow 3, a first working bellows 1 and a second working bellows 2 are arranged at the flow delivery end of the elbow, and a balance bellows 6 is arranged at the blind end of the elbow. In order to reduce the huge impact and noise on the blind plate 7 of the pressure-balanced expansion joint of the curved pipe caused by the unbalanced flow velocity of the medium caused by the instantaneous pressure fluctuation in the pipeline system, the present invention makes the following improvements to the balance hole structure at the curved pipe: A shielding plate 4 is provided at the corner of the tube 3, and a flow gap H is left between the lower part of the shielding plate and the elbow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com