Three-nozzle offset inclination angle induced air smoke evacuator

A technology of induced draft, exhaust, and offset, applied in waste heat treatment, furnace, lighting and heating equipment, etc., can solve the problems of unstable kiln pressure, failure of impeller dynamic balance, corrosion of bearing bush of fan, etc., to overcome turbulent flow resistance. Hysteresis, solving dynamic balance failure, low consumption and energy saving effect of smoke exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

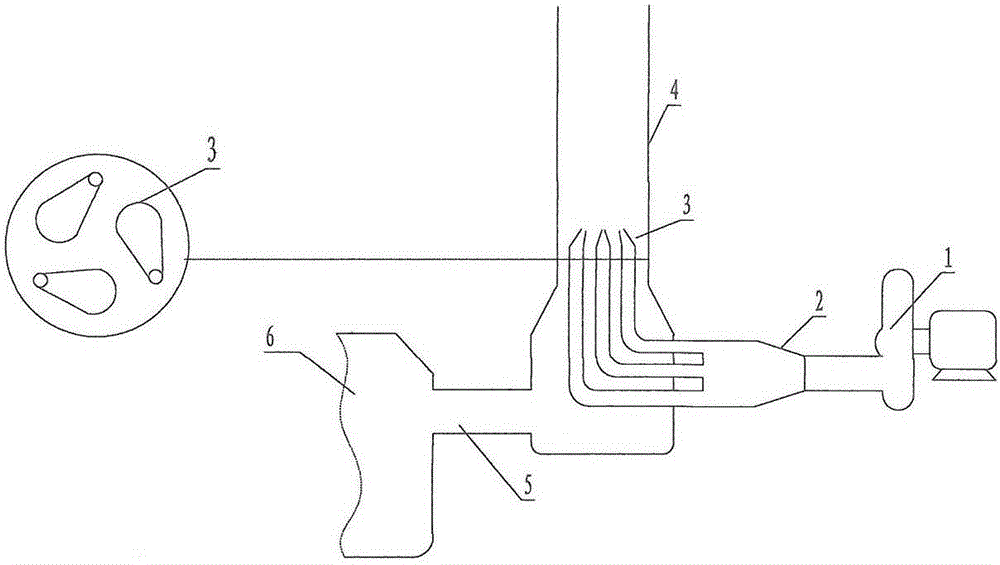

[0008] Combine below figure 1 The implementation of the present invention will be described.

[0009] figure 1 Among them, the end outlet of the air outlet pipe (2) connected to the fan (1) is connected with three offset angle spray heads (3), and the three offset angle injection heads (3) are installed near the side of the flue (4) , the flue (4) is connected to the flue and the kiln tail gas inlet (5), and the tail gas inlet (5) is next to the kiln (6).

[0010] The blower (1) injects high-pressure air into the jet flue (4) through three offset nozzles (3) to create a negative pressure, and the three high-speed air flows engulf the flue gas in the flue (4) to form a spiral air flow In this way, the aerodynamic turbulent zone formed in the middle and lower part of the flue (4) is basically eliminated, and the problem of stagnation is solved, and the flue gas in the kiln (6) is quickly discharged. This not only meets the non-contact requirements, but also overcomes the aero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com