Intrinsic safe explosion-proof magnetic switch

A magnetic switch and intrinsically safe technology, applied in the direction of magnetic/electric field switches, electric switches, electrical components, etc., can solve the problems of hidden sparks in contacts, increased volume, increased manufacturing costs, etc., and achieve the effect of eliminating hidden dangers of medium leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the present invention easier to understand, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

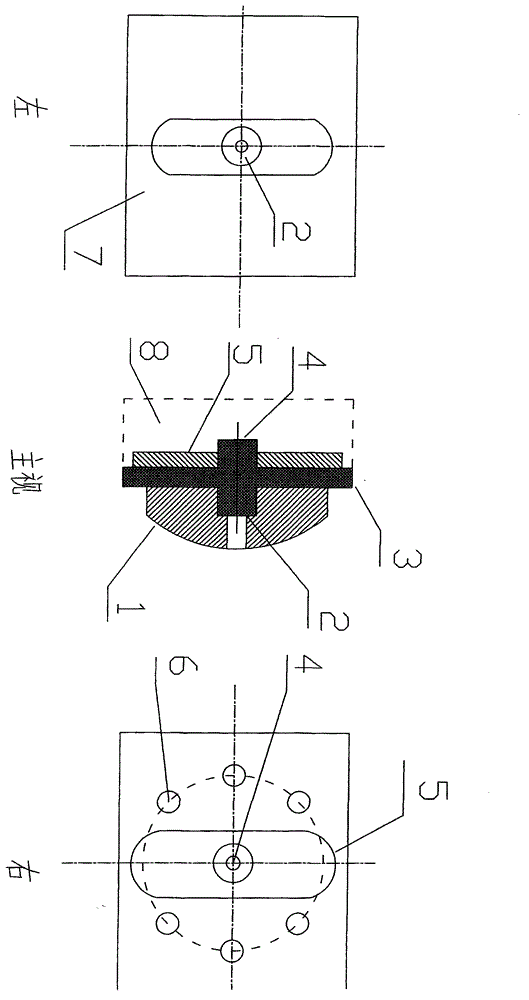

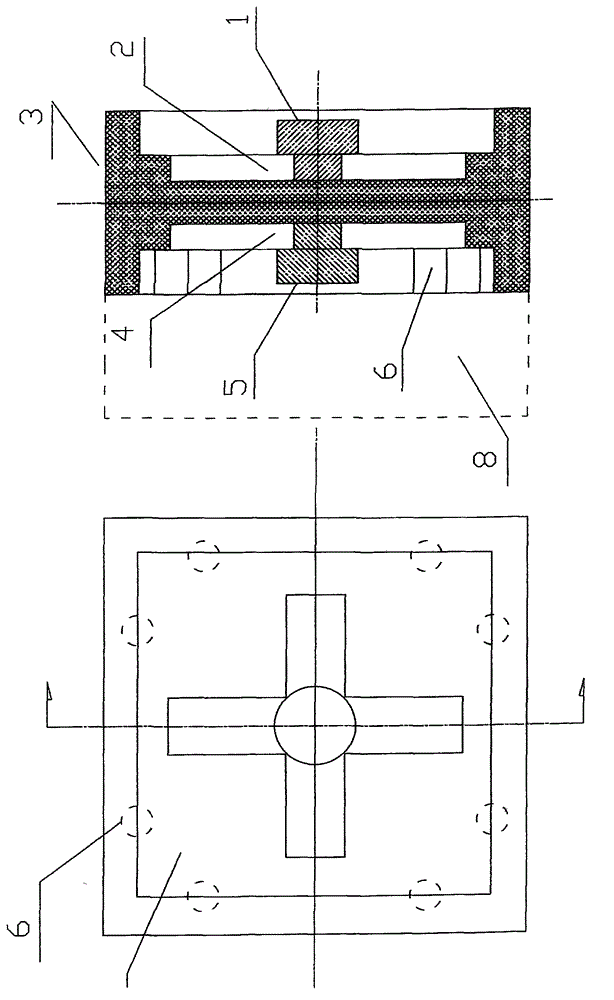

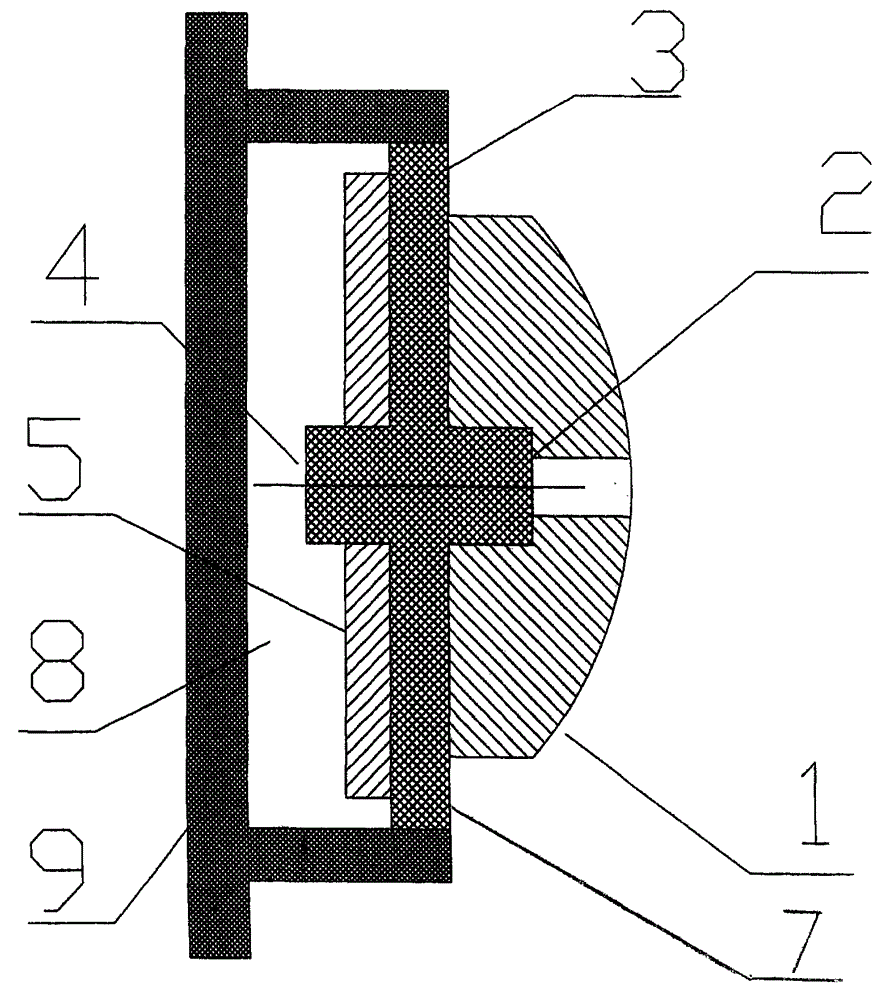

[0030] figure 1 , figure 2 The schematic view of the structure of the control working surface in the rotation mode of the present invention and the schematic view of the structure of the control work surface in the sliding mode of the present invention are respectively shown. Reference figure 1 , figure 2 , The intrinsically safe explosion-proof magnetic switch of the present invention includes a sealed housing 3, a displacement module 5 and an active magnetic module handle 1. Protruding positioning shafts 4 ( figure 1 ) And 2( figure 1 ) Or symmetrically recessed track groove 4 ( figure 2 ) And 2( figure 2 ) Used to unify the movement mode and path of the displacement module 5 inside the sealed housing and the handle 1 of the active magnetic module outside the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com