Novel sulfate solvent for lithium ion secondary battery

A secondary battery and sulfuric acid ester technology, which is applied in the field of electrochemical and chemical power supply products, can solve the problems of poor compatibility, insufficient compatibility of positive or negative electrodes, insufficient compatibility of graphite negative electrodes, etc., and achieve the effect of small cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] In a glove box full of argon gas, the sulfuric acid ester solvent of the present invention is used to prepare an electrolyte, the lithium salt used is LiTFSI, the concentration of LiTFSI in the electrolyte is 1M, and the sulfuric acid ester compound used is disulfuric acid Butyl ester, the specific structure is as follows:

[0017]

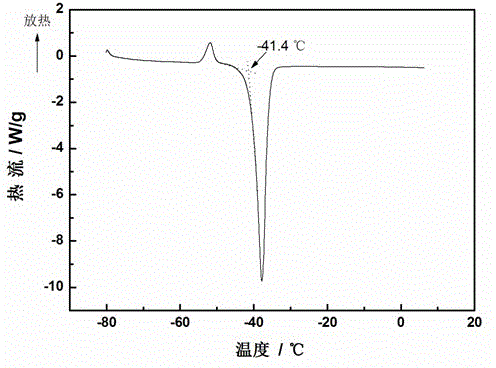

[0018] The dibutyl sulfate has a low melting point, as attached figure 2 As shown, it is about -41°C, which can broaden the selection of solvents for the low-temperature electrolyte system of lithium-ion batteries.

Embodiment 2

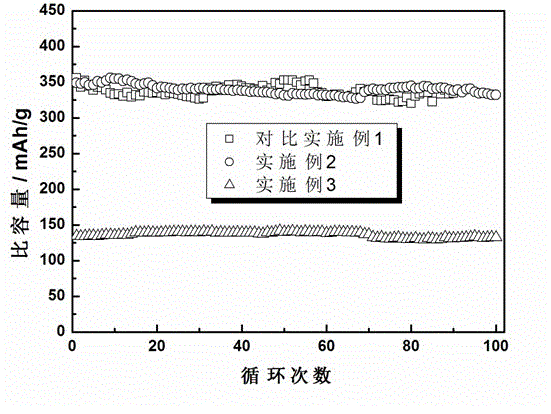

[0020] MCMB / Li 2016 button cells were assembled in a glove box filled with argon gas, using the electrolyte prepared from the new solvent described in Example 1, the charge and discharge voltage range was 0-3 V, and the current density was 40 mA / g. The test results are attached by image 3 It can be seen that for the MCMB negative electrode, the charging specific capacity in the first week is 349 mAh / g (coulombic efficiency is 75% in the first week), the charging specific capacity after 100 cycles is 332 mAh / g, and the capacity retention rate is 95%. The electrolyte prepared by the solvent has similar properties to the blank electrolyte of Comparative Example 1, indicating that the electrolyte using the new solvent has good compatibility with the negative electrode.

Embodiment 3

[0022] Assembling LiFePO in an argon-filled glove box 4 / Li 2016 button battery, using the electrolyte solution prepared by the new solvent described in Example 1, the charge and discharge voltage range is 3-4V, and the current density is 40 mA / g. The test results are attached by image 3 Visible, for LiFePO 4 The positive electrode has a discharge specific capacity of 134 mAh / g in the first week (the Coulombic efficiency of the first week is 88%), and after 100 cycles, the discharge specific capacity is 132 mAh / g, and the capacity has basically no attenuation, indicating that the electrolyte prepared by using the new solvent to LiFePO 4 The performance of the positive electrode is not greatly affected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com