Paying-off device

A technology of pay-off and runner, which is applied to the arrangement of the reel take-up reel/photosensitive drum, etc., can solve the problems of complex structure of the pay-off, easy bending of wires, and folding, etc. The effect of improving work efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

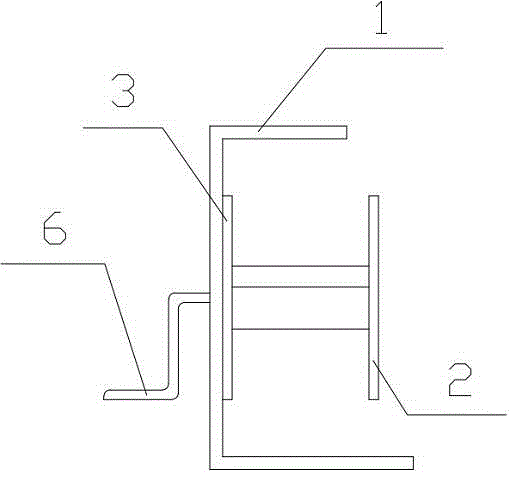

[0021] A pay-off device, comprising a bracket 1 and a runner, the runner is fixed in the middle of the bracket 1; the runner includes a fixed baffle 3, a lead screw 4, a sleeve shaft 5, a telescopic frame, and a movable baffle 2;

[0022] A handle 6 is provided at the outer axis position of the fixed baffle 3, and a lead screw 4 is provided at the inner axis position of the fixed baffle 3, and the handle 6 passes through the fixed baffle 3 and is fixedly connected with one end of the lead screw 4;

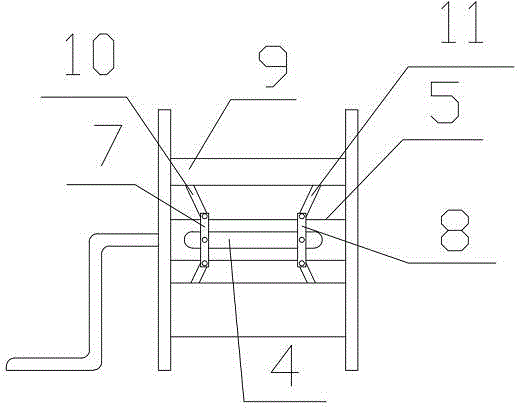

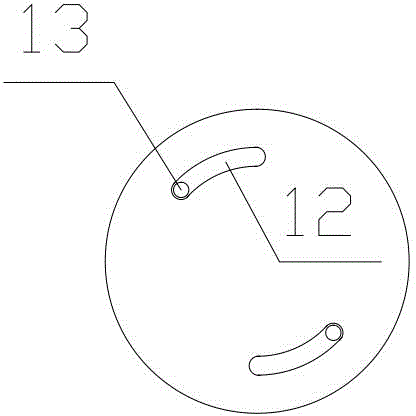

[0023] The sleeve shaft 5 is ring-sleeved on the outside of the lead screw 4, and the sleeve shaft 5 is evenly provided with three longitudinal slotted holes;

[0024] The telescopic frame is made up of the first collar 7, the second collar 8 and three telescopic brackets with the same structure;

[0025] Telescopic bracket is made up of arc plate 9, first support bar 10 and second support bar 11, and arc plate 9 is hinged with first support bar 10, and arc plate 9 is hinged with s...

Embodiment 2

[0033] A pay-off device, comprising a bracket 1 and a runner, the runner is fixed in the middle of the bracket 1; the runner includes a fixed baffle 3, a lead screw 4, a sleeve shaft 5, a telescopic frame, and a movable baffle 2;

[0034] A handle 6 is provided at the outer axis position of the fixed baffle 3, and a lead screw 4 is provided at the inner axis position of the fixed baffle 3, and the handle 6 passes through the fixed baffle 3 and is fixedly connected with one end of the lead screw 4;

[0035] The sleeve shaft 5 is ring-sleeved on the outside of the lead screw 4, and the sleeve shaft 5 is evenly provided with three longitudinal slotted holes;

[0036] The telescopic frame is made up of the first collar 7, the second collar 8 and three telescopic brackets with the same structure;

[0037] Telescopic bracket is made up of arc plate 9, first support bar 10 and second support bar 11, and arc plate 9 is hinged with first support bar 10, and arc plate 9 is hinged with s...

Embodiment 3

[0041] A pay-off device, comprising a bracket 1 and a runner, the runner is fixed in the middle of the bracket 1; the runner includes a fixed baffle 3, a lead screw 4, a sleeve shaft 5, a telescopic frame, and a movable baffle 2;

[0042] A handle 6 is provided at the outer axis position of the fixed baffle 3, and a lead screw 4 is provided at the inner axis position of the fixed baffle 3, and the handle 6 passes through the fixed baffle 3 and is fixedly connected with one end of the lead screw 4;

[0043] The sleeve shaft 5 is ring-sleeved on the outside of the lead screw 4, and the sleeve shaft 5 is evenly provided with three longitudinal slotted holes;

[0044] The telescopic frame is made up of the first collar 7, the second collar 8 and three telescopic brackets with the same structure;

[0045] Telescopic bracket is made up of arc plate 9, first support bar 10 and second support bar 11, and arc plate 9 is hinged with first support bar 10, and arc plate 9 is hinged with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com