Charger and construction method thereof

A construction method and charger technology, which is applied in the direction of current collectors, electric vehicles, electrical components, etc., can solve the problems of reduced power utilization of chargers, affecting the quality of AC power supply, and reactive power loss of AC power supply, and achieve low manufacturing costs. The effect of high power utilization rate and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

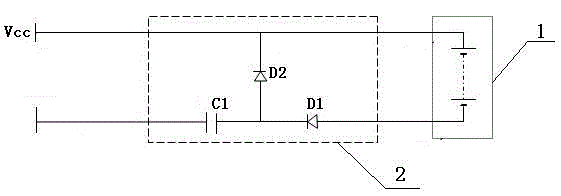

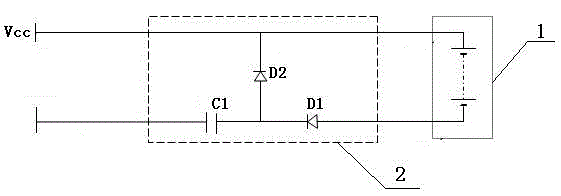

[0020] Embodiment 1: see figure 1 , the charger constructed by the above method includes a charging unit 2 that connects the battery 1 to a power supply, the power supply is a 220V, 50Hz single-phase AC power supply, including live wires and neutral wires, and the charging unit 2 includes a high-voltage capacitor C1, a first rectifier Diode D1 and the second rectifying diode D2, one end of the high-voltage capacitor C1 is connected to the live wire, the other end is connected to the negative pole of the first rectifying diode D1, the positive pole of D1 is connected to the negative pole of the battery 1, the positive pole of the battery is connected to the neutral line, and the negative pole of the second rectifying diode D2 is connected to The neutral line, the anode of D2 is connected to the connection point of the high voltage capacitor C1 and the first rectifier diode D1.

Embodiment 2

[0021] Example 2: see figure 2 , the power live wire and the zero line are provided with a linkage switch and a discharge resistor R1. The linkage switch is a double-pole single-throw switch or any form of contact switch, which can be a commercial switch or self-made by a metal sheet. The present invention uses a double Single-pole single-throw switch; when the battery door is opened, the switch is turned off, and the charger is physically isolated from the AC grid; when the battery door is closed, the switch is closed and charging starts; a discharge resistor is connected in parallel to the AC power supply or the high-voltage capacitor C1, and the resistance value Greater than 510 kΩ.

[0022] A linkage switching switch and a discharge resistor R1 are set on the live wire and the zero line of the power supply. The linkage switching switch is a double-pole single-throw switch or any form of contact switch, which can be a commodity switch or made by a metal sheet. The present ...

Embodiment 3

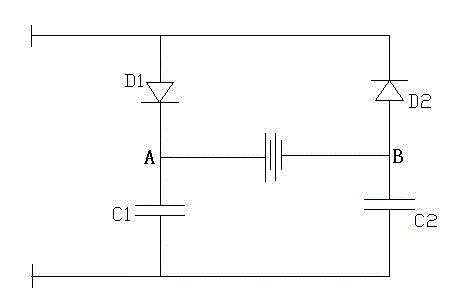

[0028] Embodiment 3: see image 3 A charger with another circuit structure constructed by the above method includes a charging unit 2 connected to a battery 1 and an AC power supply, the AC power supply includes live wires and neutral wires, and the live wires and neutral wires are respectively connected in series with the first A rectifier diode D1, a high-voltage capacitor C1, a second rectifier diode D2, and a high-voltage capacitor C2, and a battery 1 is connected in series between the first rectifier diode D1 and the second rectifier diode D2.

[0029] Application of Embodiment 1: philishave 46 rechargeable electric shaver produced by philips company, the original charging part circuit is removed, and the high-voltage capacitor C1, the first rectifier diode D1 and the second rectifier diode D2 are figure 1 The circuit is connected to form a charging unit, and all the charging units are placed in an insulating shell, and then the charging unit is connected to the battery. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com