Specimen transportation system and method for controlling same

A technology of conveying system and control method, which is applied in the direction of program control, general control system, control/regulation system, etc., and can solve the problems of shortening processing time and occupying conveying lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

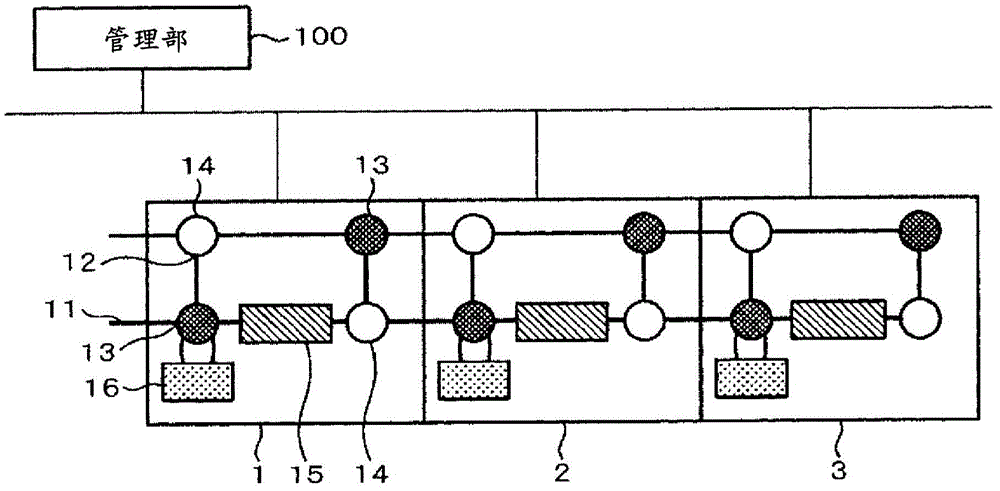

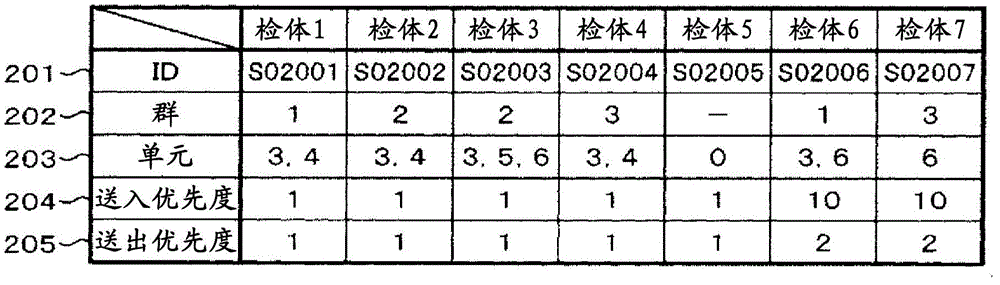

[0029] in figure 1 Represents the transport model of the specimen transport system. In addition, in Figure 5 Shows the overall system diagram of a specific specimen transport system.

[0030] The specimen transportation system of this embodiment is connected with a plurality of preprocessing units 1, 2, and 3. The specimen loaded on the test tube rack is transported to each pretreatment unit through the transport line 11 and the joining line 12, and necessary processing is performed. Through the combination of the conveying line 11 and the joining line 12, a confluence point 13 and a branch point 14 are generated.

[0031] In addition, with figure 1 The main transport line 11 that transports the specimen from left to right, and the return line that transports the processed specimen from right to left. Assume that the confluence point is in any line, and it is set upstream of the branch line.

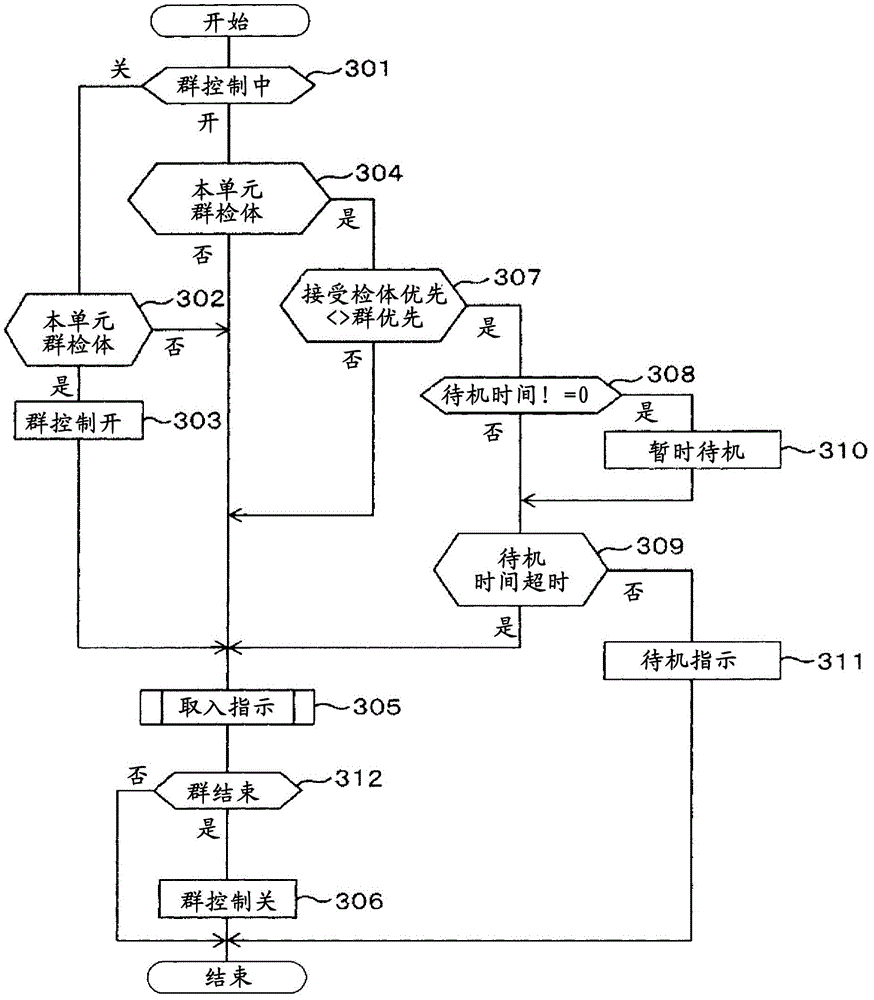

[0032] If the confluence point 13 accepts the sample subject to group management, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com