Conveying device of dry type desulfurizing agent

A technology of conveying device and desulfurizer, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., and can solve problems such as outlet blockage, high maintenance cost, and difficult system maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

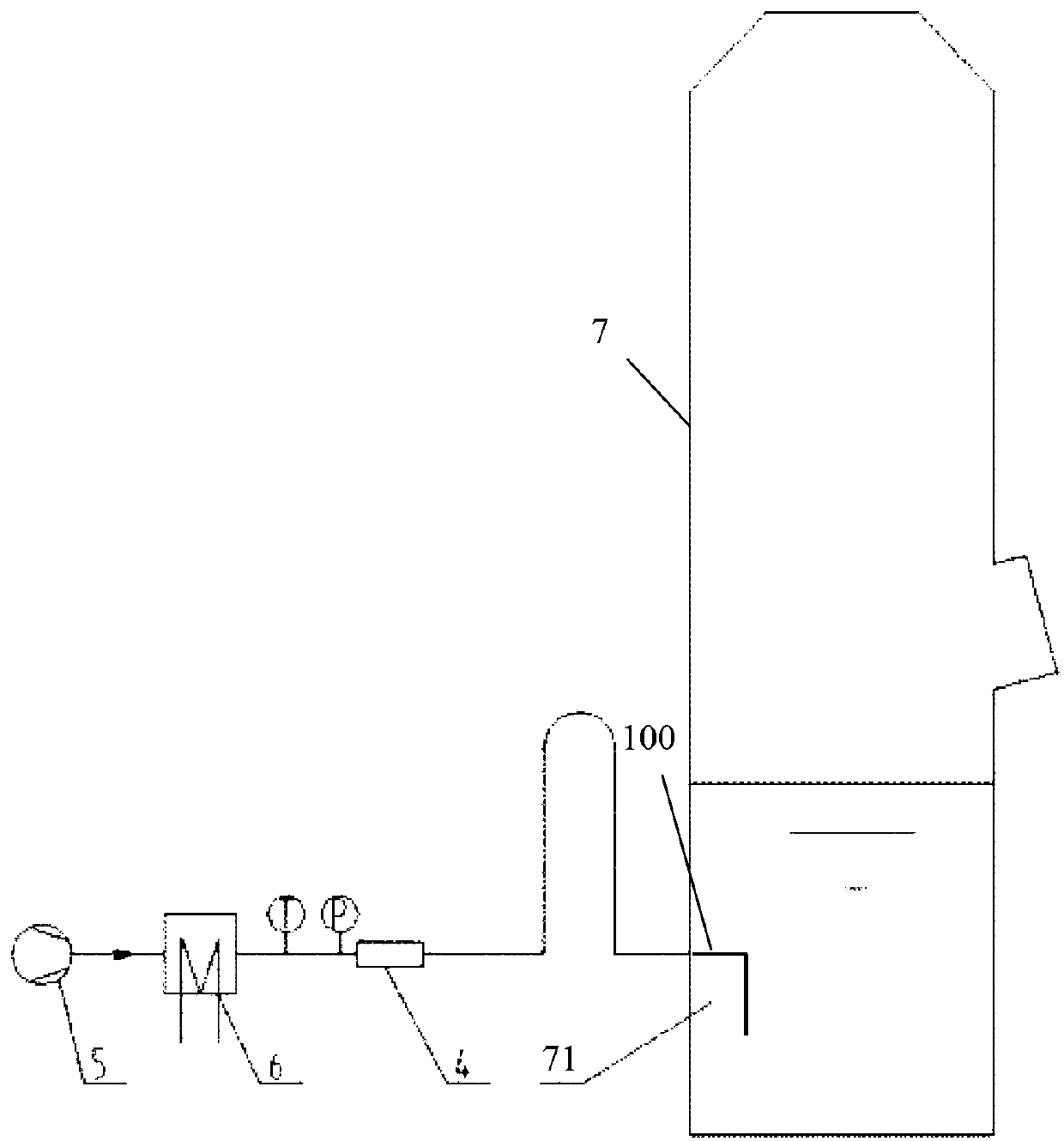

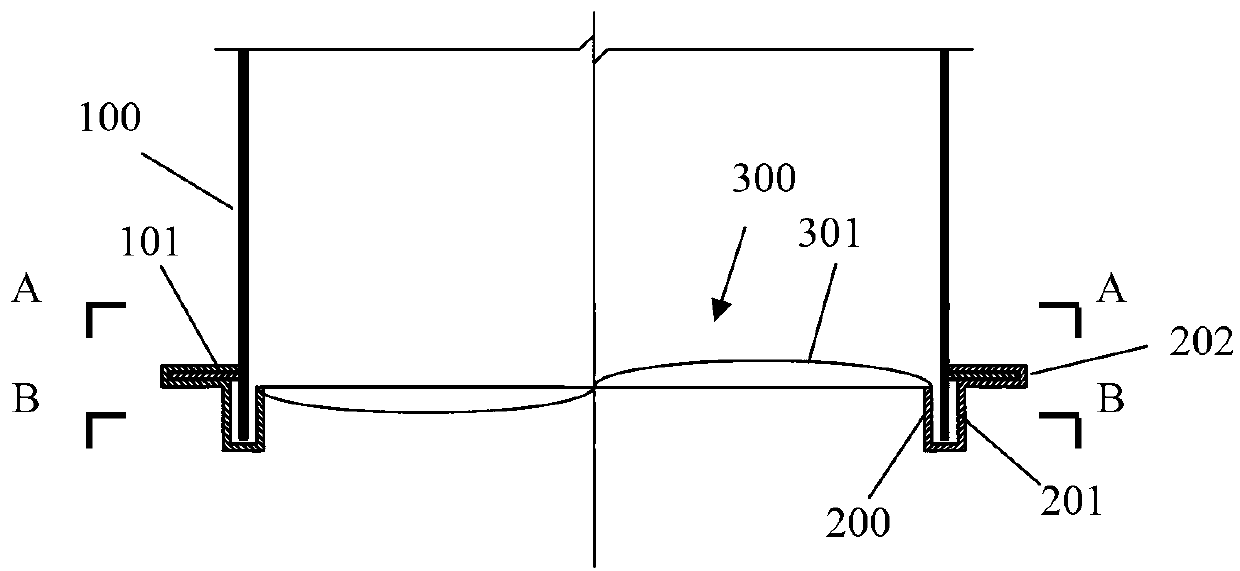

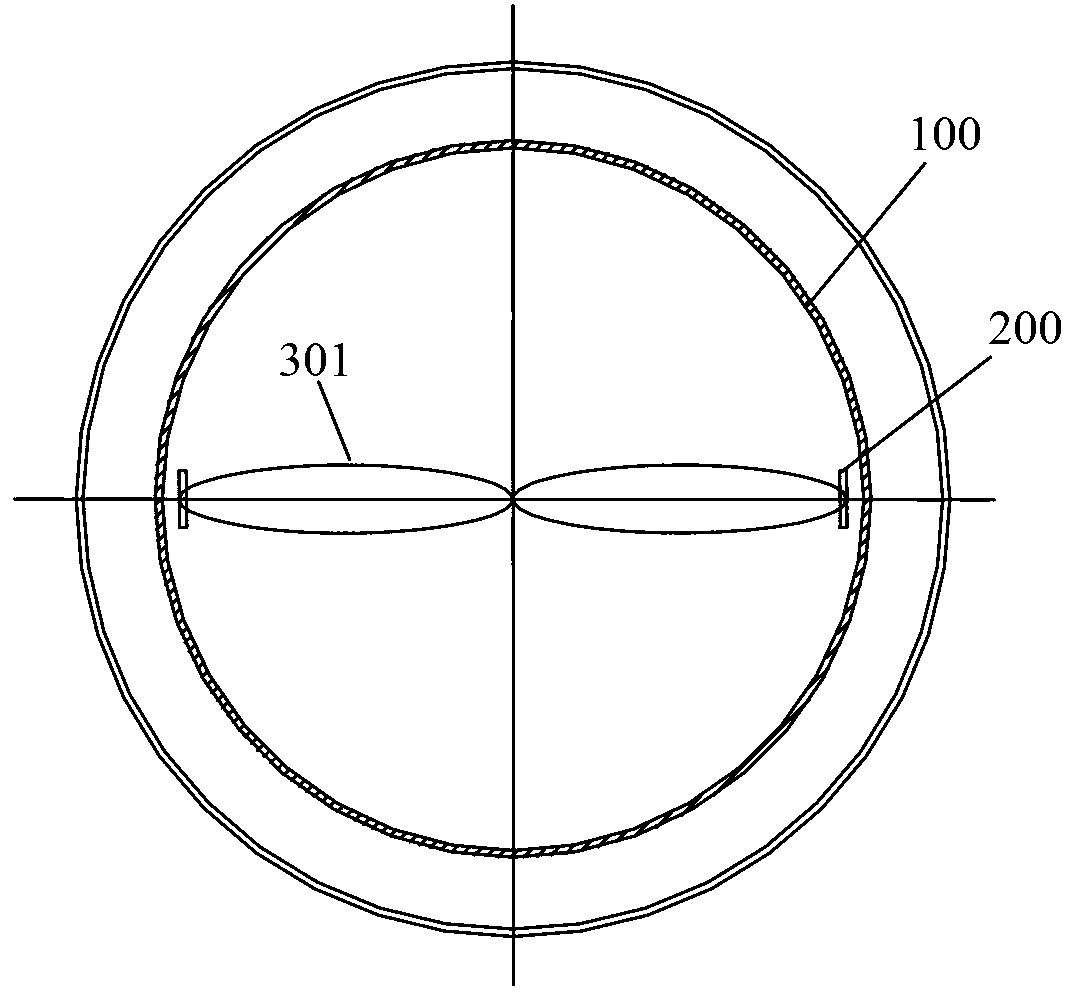

[0019] Such as figure 1 As shown, the delivery device for dry desulfurization agent of the present invention includes an oxidation blower 5 , an oxidation air cooler 6 , a dilute phase conveyor 4 , and a desulfurization agent delivery pipe 100 .

[0020] Wherein, the dilute phase conveyor 4 includes a material inlet, an air inlet, and a material outlet. The oxidation blower 5 is connected to the air inlet of the dilute phase conveyor 4 through the oxidation air cooler 6 . The outlet of the dilute phase conveyor 4 is connected to a desulfurization agent delivery pipe 100 , and the desulfurization agent delivery pipe 100 extends into the slurry pool 71 of the desulfurization tower 7 .

[0021] The dry desulfurizer enters from the feed port of the dilute phase conveyor 4 . Oxidation fan 5 sprays oxidizing air into the slurry pool of the absorption tower, and the oxidizing air oxidizes calcium sulfite in the slurry pool of the absorption tower to calcium sulfate, and then crysta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com