A brush-fed needle-free electrospinning device and method

An electrospinning and brush technology, which is applied in textiles and papermaking, filament/thread forming, feeding solution to the spinneret, etc., can solve the problems of easy blockage of pinholes, time-consuming and labor-consuming, and regular cleaning, etc. Achieve the effects of modular expansion, simple device structure and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

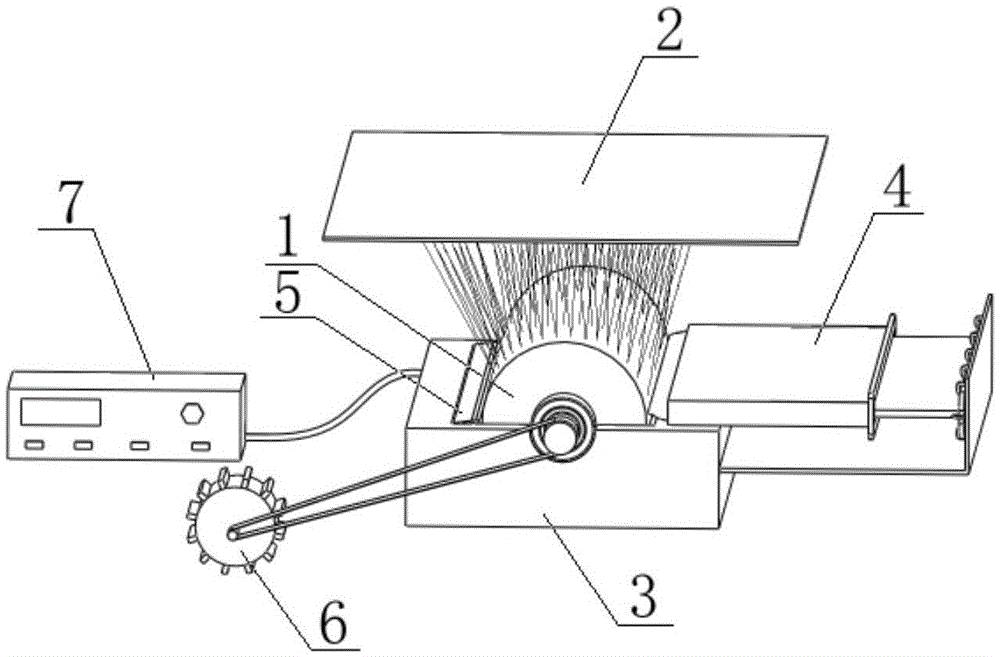

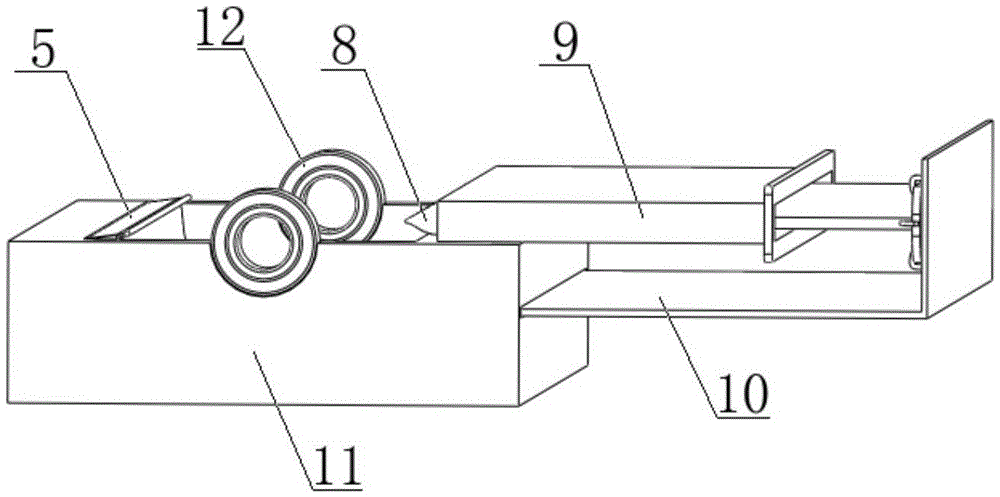

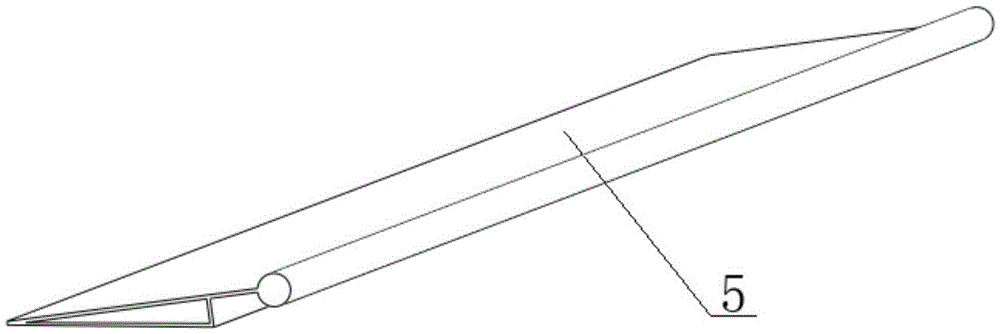

[0022] A brush feeding type needle-free electrostatic spinning device and method of the present invention, such as figure 1 As shown, the device mainly includes a rotary nozzle 1, a receiving plate 2, a concave support 3, a brush feeding system 4, a baffle 5, a motor 6 and an electrostatic generator 7. The concave support 3 is composed of a concave groove 11 and a support bearing 12, and the rotary nozzle 1 is placed on the support bearing 12; the brush feeding system 4 is composed of a brush 8, an injection chamber 9 and a micro-flow metering pump 10. The straight line at the tip of the brush 8 is parallel to the axis of the rotary nozzle 1, and the brush 8 is in contact with the rotary nozzle 1; the baffle plate 5 is placed on the concave groove 11, and the distance between the cylindrical scraper and the rotary nozzle 1 is 0.3-1 mm; the motor 6 The rotating nozzle 1 is controlled by a belt drive to rotate; the receiving plate 2 is placed on the upper end of the rotating noz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com