Automatic hydraulic rock breaking pick

A rock-breaking and hydraulic technology, which is applied in the field of self-controlled hydraulic rock-breaking picks, can solve problems such as difficult cooling of picks, affecting the efficiency of the working face, and difficult control of jet flow, so as to eliminate the lag of ejection time and eliminate the easy clogging of nozzles , the effect of reducing traffic consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

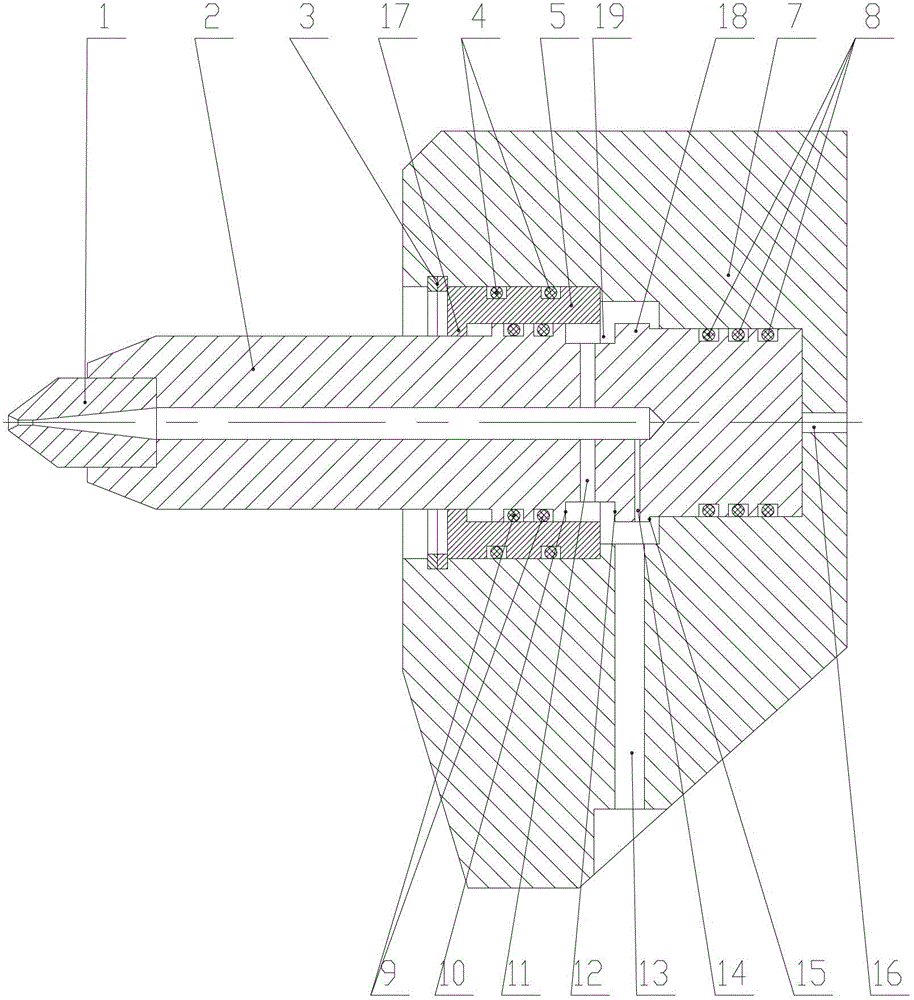

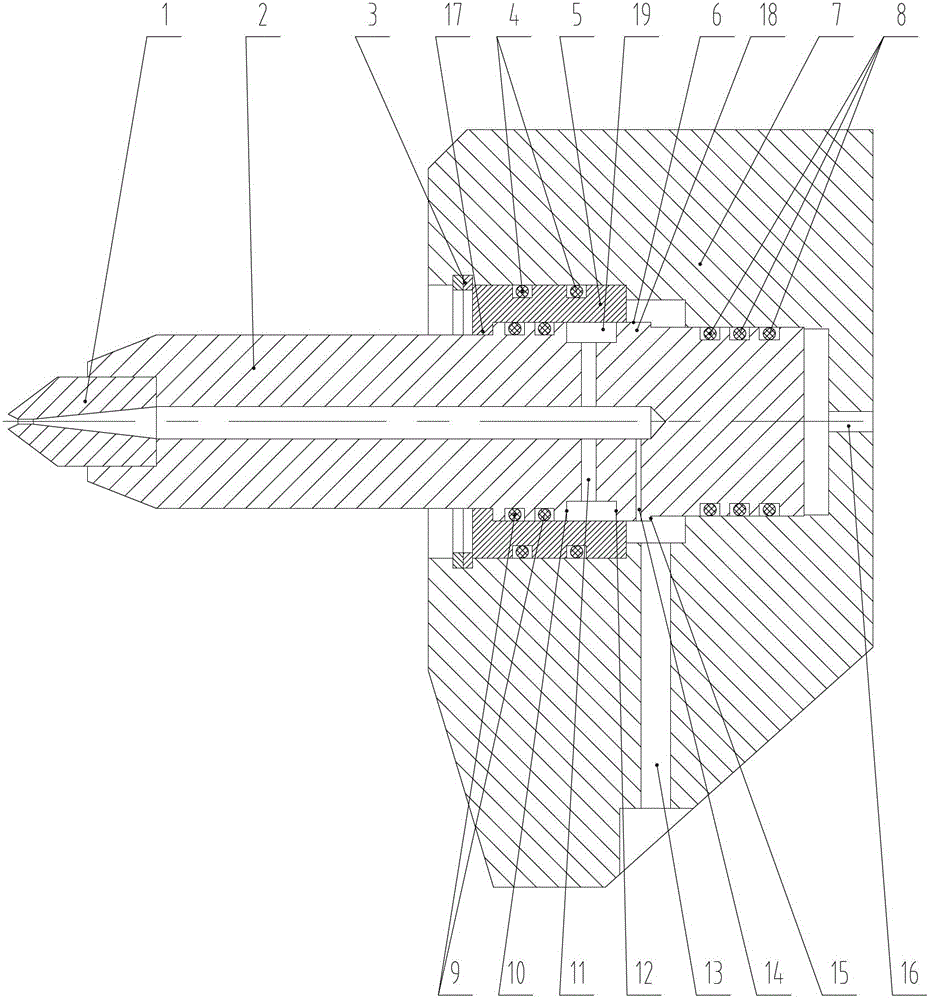

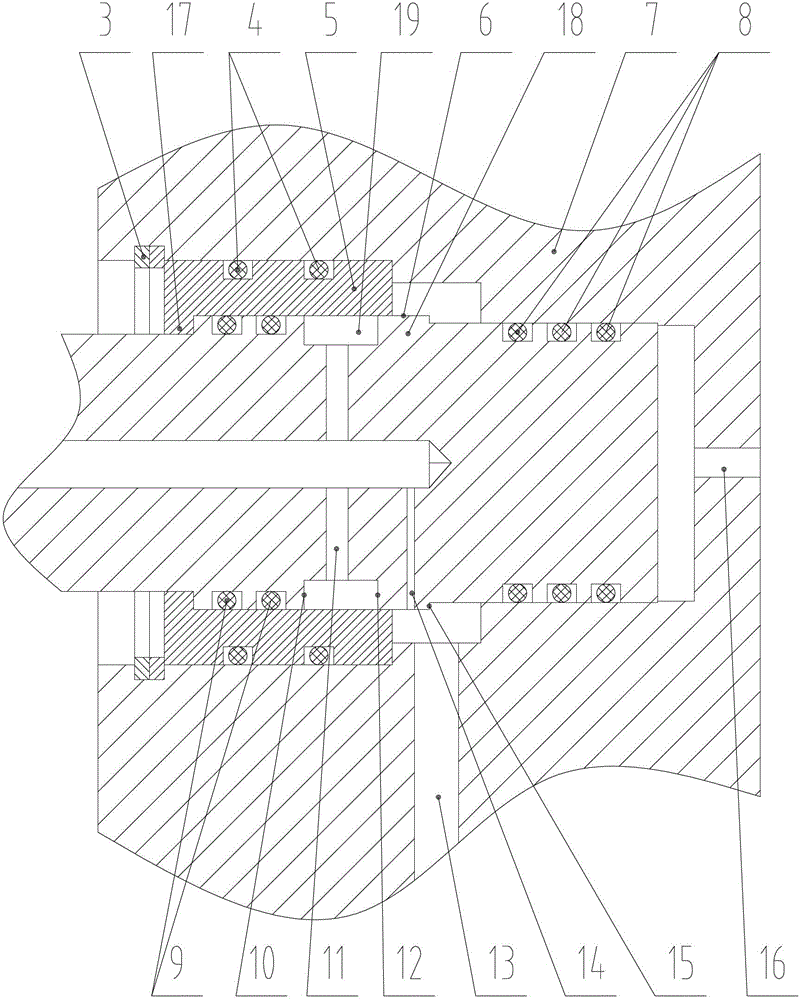

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

[0021] Such as Figures 1 to 3 As shown, the self-controlled hydraulic rock-breaking pick of the present invention includes a tip nozzle body 1, a tooth handle 2, a valve sleeve 5 and a tooth seat 7. The front end of the tooth handle 2 is welded to fix the tip nozzle body 1, and the tail end of the tooth handle 2 extends into the cavity of the tooth seat 7; the valve sleeve 5 is fixed in the cavity of the tooth seat 7 through the elastic retaining ring 3, and the inner wall of the valve sleeve 5 is close to the tooth handle 2 One side of the front end is provided with an annular protrusion 17; an annular shoulder 18 matching the valve sleeve 5 is provided at the tail end of the tooth handle 2, and an annular groove 19 is opened on the annular shoulder 18. The tip nozzle body 1 is provided with a spray hole in the axial direction, and the tooth handle 2 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com