A string type electrospinning device and method

An electrospinning and string device technology, which is applied in the field of string-type electrospinning devices, can solve problems such as loss, air breakdown, and high power, and achieve the effects of simple use, low energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

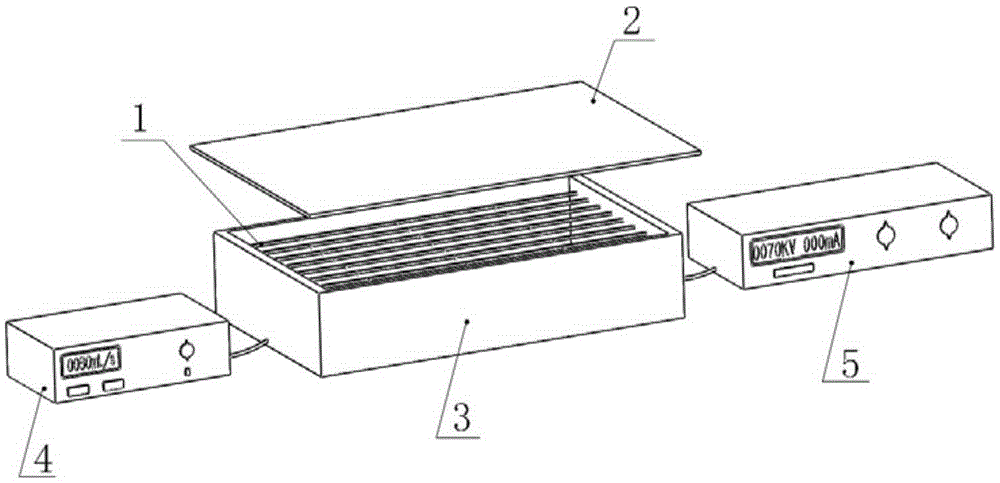

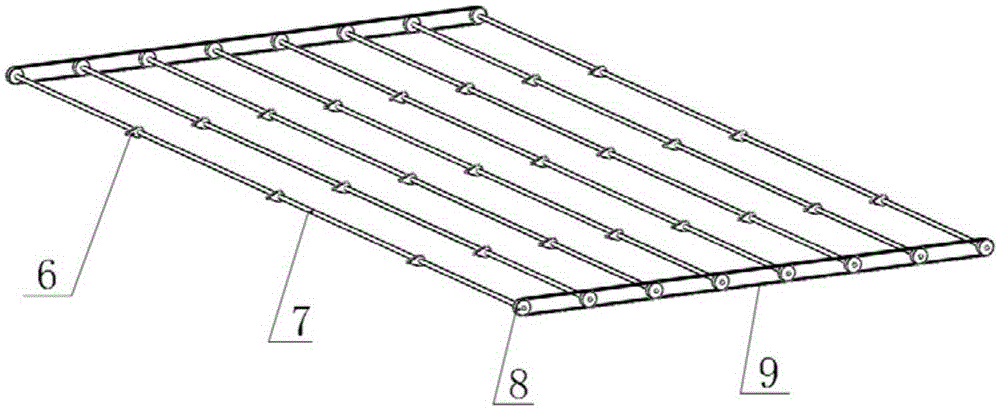

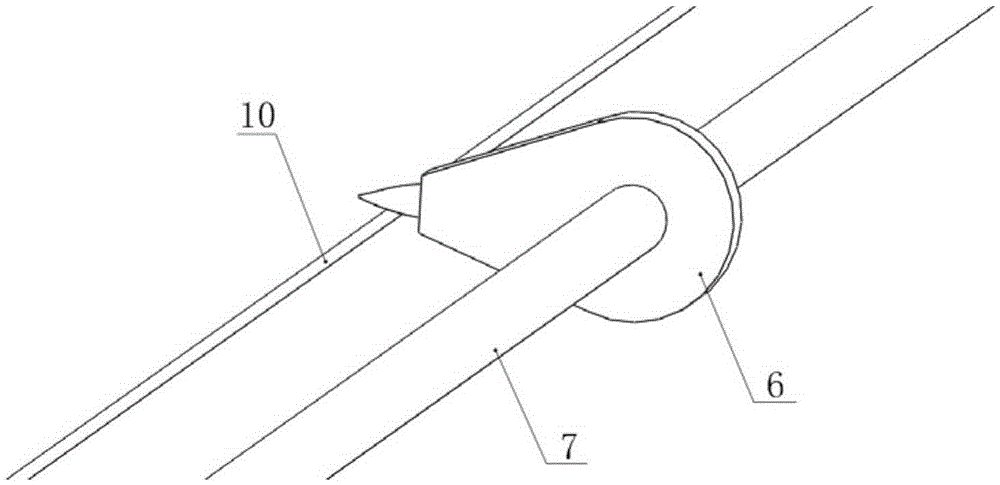

[0022] A kind of string type electrospinning device and method of the present invention, such as figure 1 As shown, it mainly includes a spinning string 10, an automatic string picking device 1, a receiving plate 2, a solution pool 3, a servo solution supply system 4, and a high-voltage electrostatic generator 5. Among them, the spinning strings 10 are arranged at the top of the solution pool 3 at equal intervals, keeping a distance of -5mm to +14mm from the solution; the automatic picking device 1 is composed of a dial head 6, a guide rail 7, a transmission wheel 8 and a transmission belt 9, and is placed in the spinning chamber. Above the string 10; the dial 6 is composed of a rubber contact 11 and a rotating cam 12, which is threaded. The dial 6 is arranged on the guide rail 7 at equal intervals, and the tip of the rubber contact 11 is placed on the spinning string 10 by 3-6mm The transmission wheel 8 and the transmission belt 9 form a pulley transmission system, which cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com