Preparation method of composite ceramic capacitor material

A technology of composite ceramics and capacitors, which is applied to the parts of fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems of increased dielectric loss, easy to generate high temperature, and poor multiplier characteristics of capacitor materials, so as to increase specific capacitance and DC resistance. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

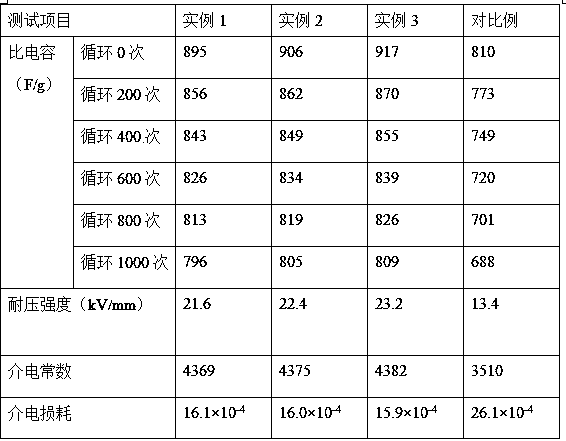

Examples

Embodiment Construction

[0027]In terms of parts by weight, dissolve 3-4 parts of citric acid in 10-12 parts of ethylene glycol, heat up to 80-90°C to obtain a mixed solution, and then use 0.5-1.0 parts of tetrabutyl titanate with 5- Dilute with 7 parts of absolute ethanol, add to the mixed solution and stir for 2.0-2.5 hours to obtain a compound solution. After the above-mentioned compound solution is cooled to 40-50°C, continue to drop 13-15 parts of Barium acetate solution, stirred and reacted for 1.0-1.5 hours, followed by adding 3-4 parts of calcium nitrate solution with a mass fraction of 10%, and 0.5-0.8 parts of a zirconium nitrate solution with a mass fraction of 20%, and mixed to obtain a polymer precursor; Put the above polymer precursor in a blast dryer with a set temperature of 100-120°C, dry for 7-8 hours to obtain a gel, and coke the gel in a muffle furnace with a temperature of 450-500°C for 4-4~ 5h, to obtain a black foam, grind the black foam to a particle size of 20-25μm, put it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com