Concrete admixture, concrete mixture containing admixture and preparation method of concrete mixture

A concrete admixture and concrete technology, applied in the field of concrete, can solve the problems of falling off, difficult to control the rapid setting time, long setting time, etc., and achieve the effect of improving the construction performance, improving the rapid setting effect, forming and dispersing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The embodiment of the present application discloses a concrete admixture, which is composed of the following components:

[0067] Accelerator 15kg; agar powder 10kg; carrageenan 5kg; konjac flour 1kg; gelatin 0.3kg; water 100kg.

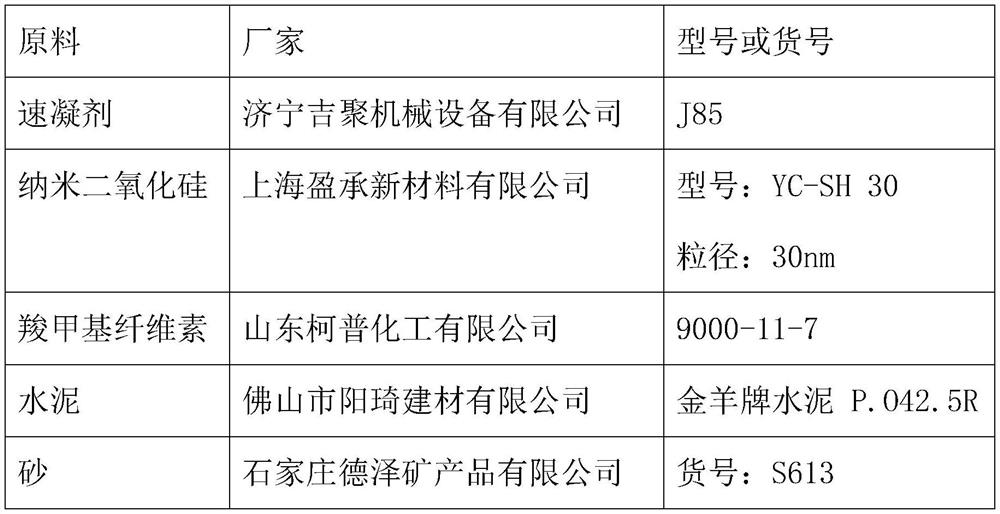

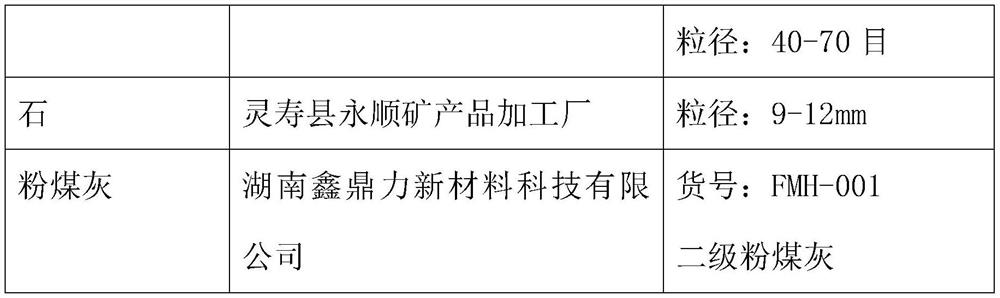

[0068] In this embodiment, the setting accelerator is the commercially available setting accelerator in Table 1.

[0069] The embodiment of the present application also discloses a preparation method of a concrete admixture, comprising the following steps:

[0070] Step 1, add agar powder, carrageenan, konjac powder and gelatin in the water according to the above mass ratio, and stir with a rotating speed of 150r / min, and heat while stirring, until the agar powder, carrageenan, konjac powder and gelatin are completely dissolved. , forming an encapsulation solution.

[0071] In step 2, the setting accelerator is added to the coating solution prepared in step 1, and stirred for 15 minutes at a rotation speed of 200 r / min, so that the setting a...

Embodiment 2

[0074] The difference with Example 1 is: the consumption of each component of the concrete admixture is different, and the consumption of each component is as follows:

[0075] Accelerator 20kg; agar powder 15kg; carrageenan 8kg; konjac flour 3kg; gelatin 1kg; water 120kg.

Embodiment 3

[0077] The difference with Example 1 is: the consumption of each component of the concrete admixture is different, and the consumption of each component is as follows:

[0078] Accelerator 18kg; agar powder 13kg; carrageenan 7kg; konjac flour 2kg; gelatin 0.5kg; water 110kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com