Equivalent material separating valve for high-flow powder materials

A powder material and material distribution valve technology, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc., can solve the problem of uneven distribution of raw materials entering the kiln, and achieve the effect of saving equipment power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

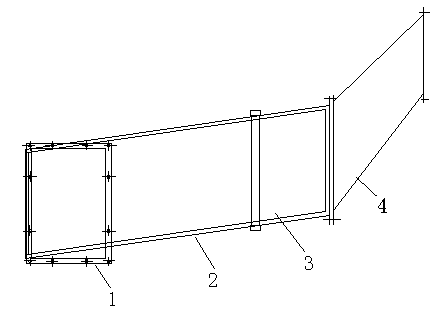

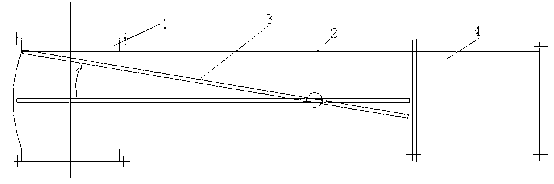

[0018] Referring to the attached figure, the equal-volume distributing valve for large-flow powder materials, the distributing valve includes a feeding slide 1, a distributing valve housing 2, a valve plate 3 and a feeding slide 4, and the valve plate 3 is made of light resin material Made, the distribution valve housing 2 is made of a steel plate of more than 3mm, and the height of the distribution valve housing 2 is more than 1.5 times the width. The valve plate 3 is set on the material distribution valve housing 2, the length of the tail section of the valve plate 3 is more than three times the length of the head section, and there is a rotation at three-quarters of the length of the valve plate 3, and the valve plate 3 is fixed on the material distribution valve. The valve housing 2 and the two sides of the material distribution valve housing 2 are respectively provided with a feed slide 1 and a discharge slide 4. After the powder material comes from the air chute, it firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com