Large-width unit plate block curtain wall

A large-width, plate technology, applied in the field of large-width unit plate curtain wall, can solve problems such as deformation of connectors, and achieve the effect of not easy to loosen and deform, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

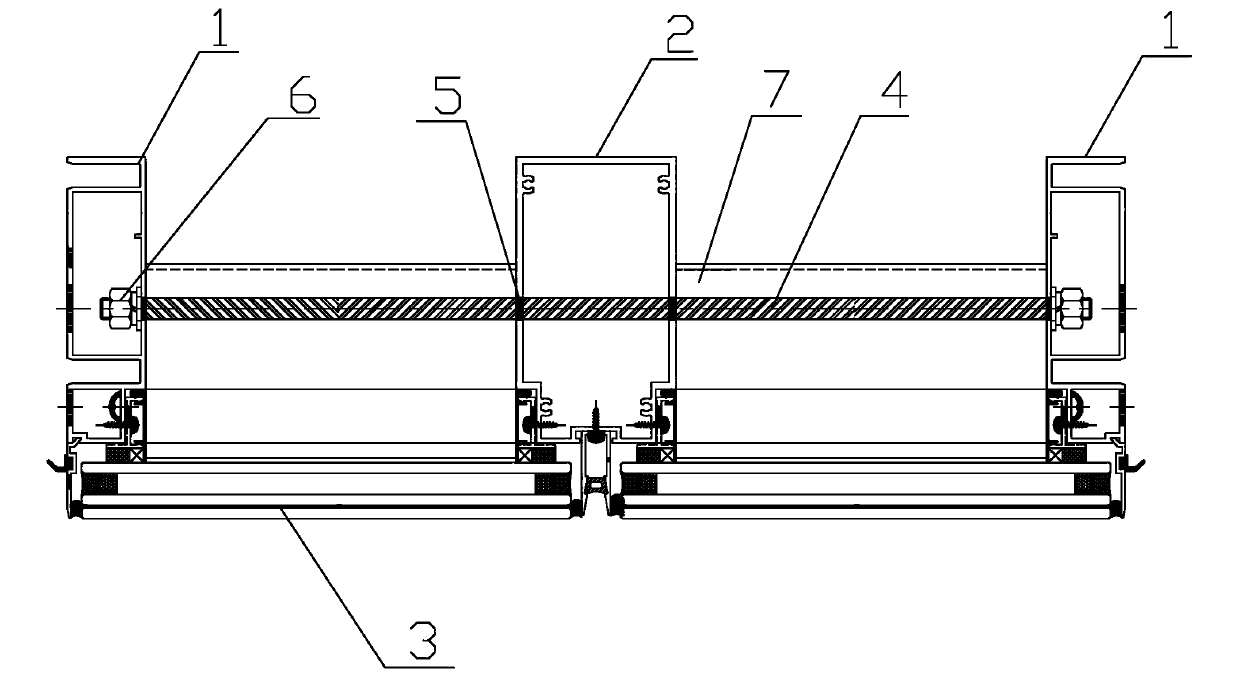

[0011] Such as figure 1 The large-width unit-slab curtain wall shown includes: column 1, center column 2, glass plate 3 and screw 4, there are multiple columns 1, center column 2 is arranged between adjacent columns 1, and mounting holes are provided on it 5. The screw 4 is a stainless steel screw with a diameter of 12 mm, which passes through the mounting hole 5, and the two ends are respectively fixed on the adjacent column 1 by the nut 6, and there is a pre-tightening force between the nut 6 and the screw 4. The plate 3 is fixed on the upright column 1 and the center column 2.

[0012] The center column 2 is set in the middle of the glass plate 3 to play a supporting role. The center column 2 and the column 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com