Rotary piston type air compressor capable of regulating compression ratio automatically

A technology of automatic adjustment and rotary piston, applied in the field of air compression device, closed motor-driven air compressor, and driving external air compressor, can solve the problems of low compression efficiency, large required driving torque, large vibration, etc., to achieve structural Reliable, reduce operating vibration, and improve the effect of compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

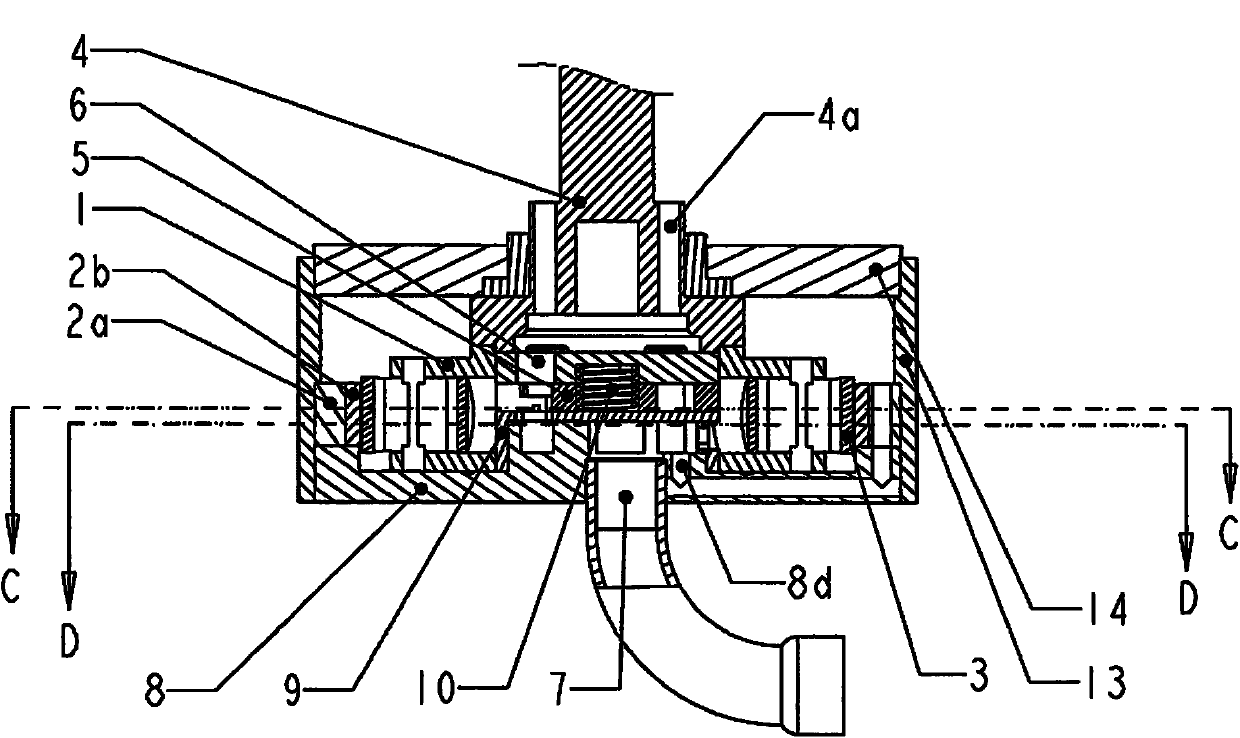

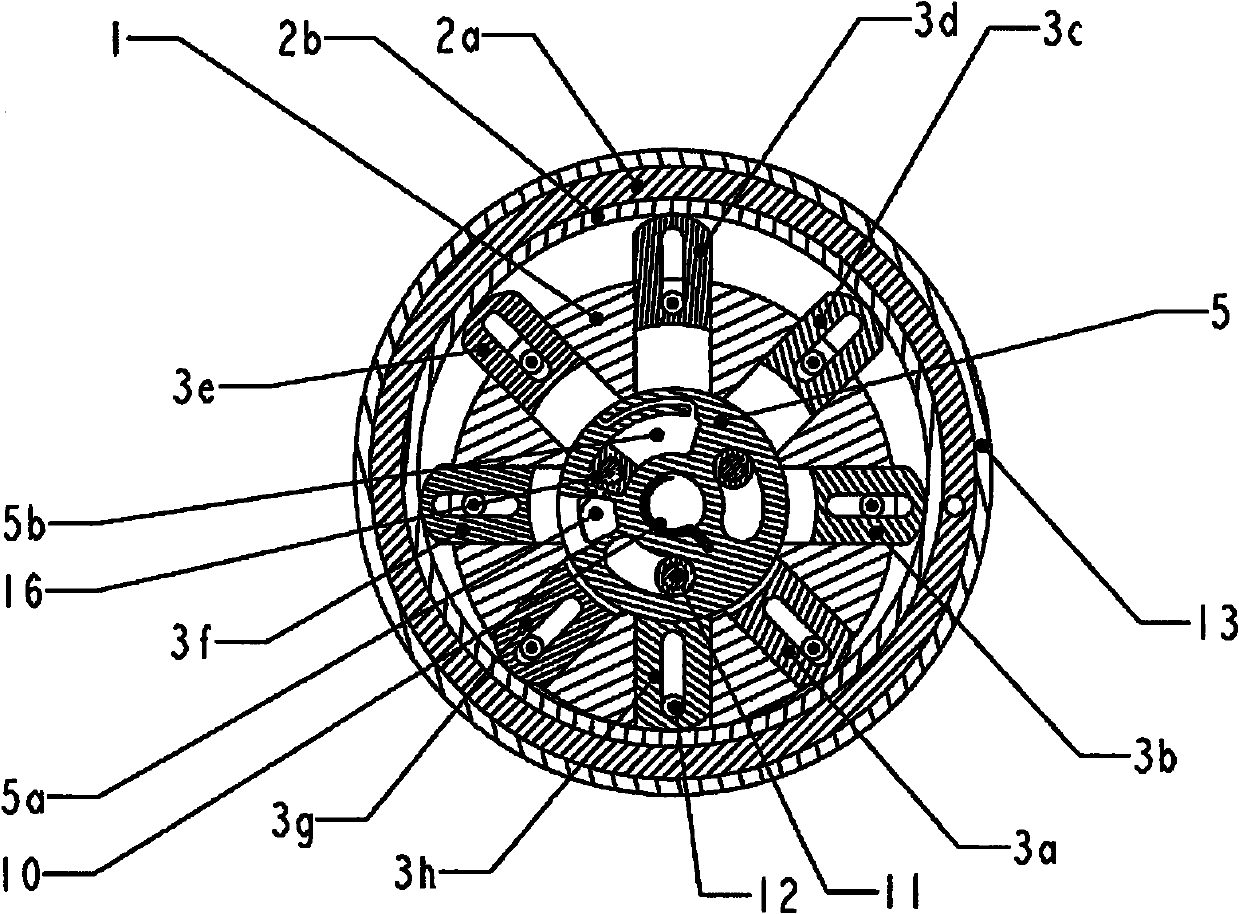

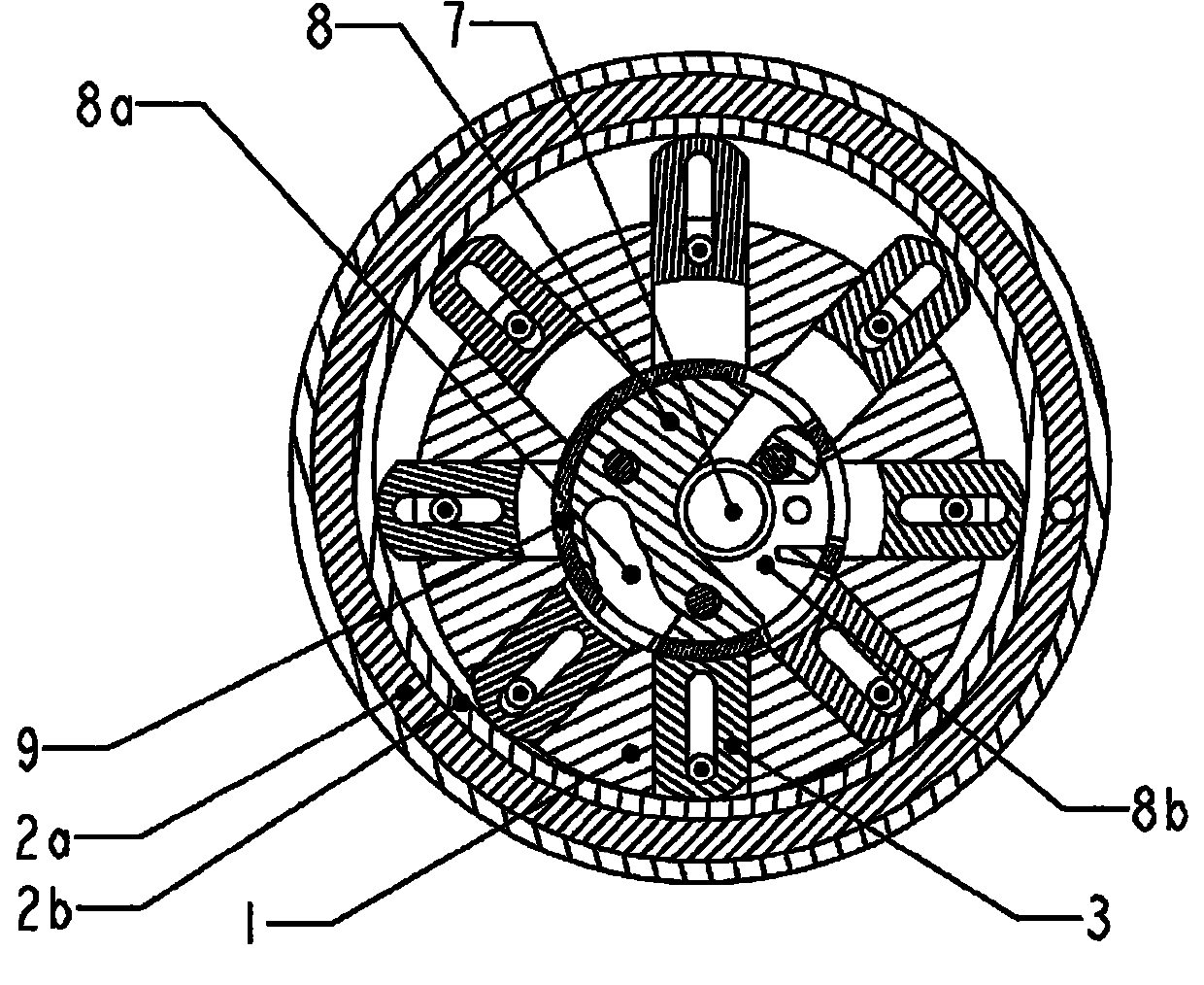

[0018] The cylinder (1) rotates counterclockwise under the drive of the drive shaft (4), and the piston (3) reciprocates radially along the cylinder (1) under the control of the centrifugal action and the offset bearing (2). Figure 1B Among them, the suction side pistons (3a, 3b, 3c, 3d) are in the suction state; the compression and exhaust side pistons (3e, 3f, 3g, 3h) are in the compression and exhaust state.

[0019] Figure 1B Among them, a pressure chamber (5b) is arranged on the compression adjustment disc (5), and the compression adjustment disc (5) is also controlled by the torsion spring (10). The air pressure in the pressure chamber (5b) and the torsion spring (10) provide the clockwise torque of the compression adjustment disc (5); the pressure at the exhaust port (5a) of the compression adjustment disc provides the counterclockwise torque of the compression adjustment disc (5); The front-stage compression cylinder chamber (where 3e is located) is connected, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com