Drum brake structure

A brake drum and drum technology, applied in the direction of the brake drum, etc., can solve the problems of low safety factor, difficult car control, steering wheel shaking, etc., and achieve the effects of improving mechanical performance, reasonable structure, and increasing overall strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below through specific embodiments and in conjunction with the accompanying drawings.

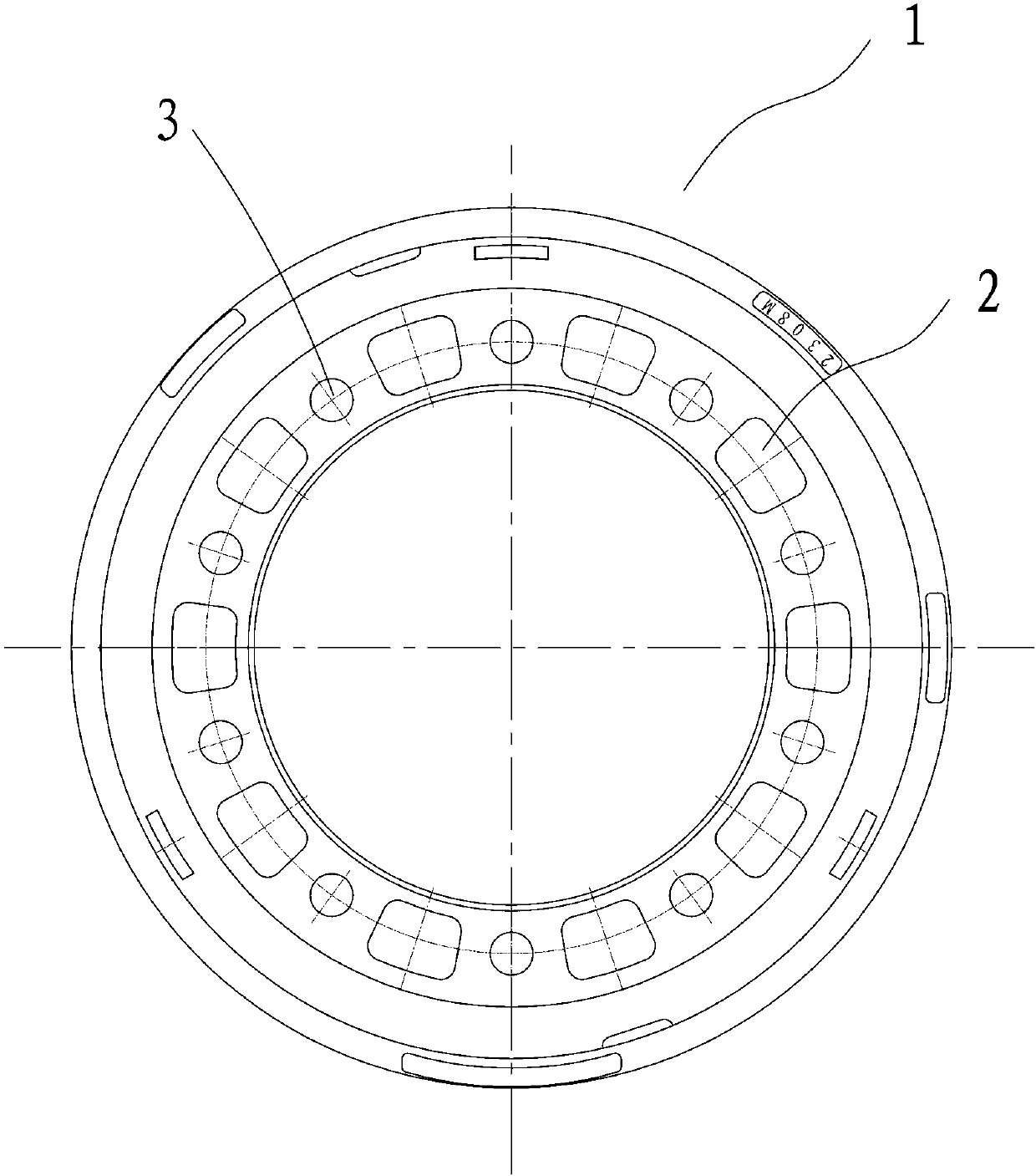

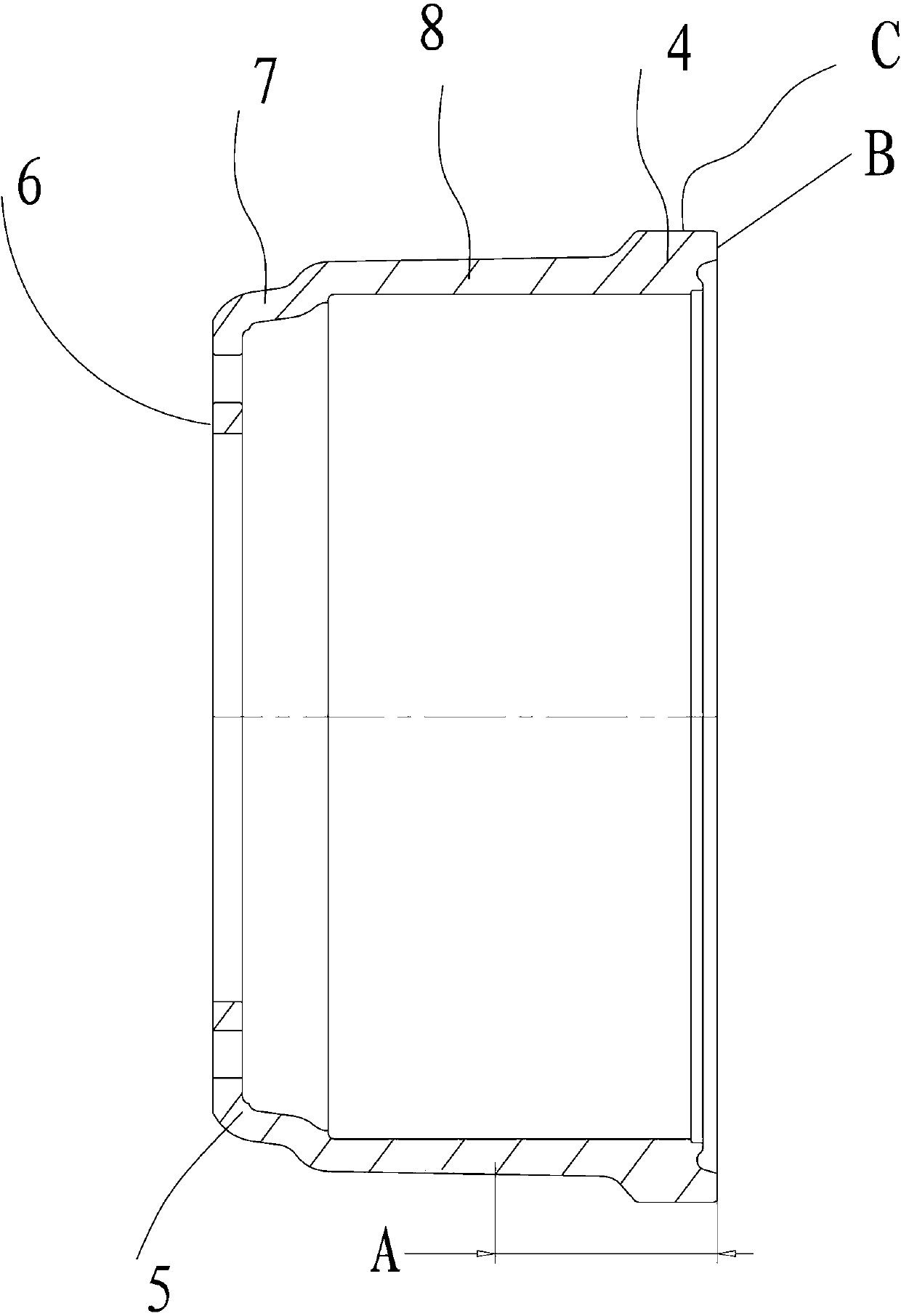

[0016] Such as figure 1 , figure 2 As shown, the brake drum 1 of the present invention includes a flange portion 6, a bottom portion 7, a drum portion 8 and a mouth portion 4, the flange portion 6 is connected to the flange of the hub, and the bottom portion 7 is connected to the flange portion 6 and the drum portion 8 , the junction transitions with a circular arc, the mouth 4 is connected to the drum 8, the mouth 4 is the opening of the brake drum, the brake drum is made by casting, and the upper and lower mold parting surfaces of the existing brake drum casting mold are located at Above the mouth, therefore, for the overall appearance, it is necessary to cut the outer surface of the mouth after the blank is processed, and the end surface is flattened, thereby weakening the strength of the mouth. In view of this, in the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com