Filtration system with outlet function

A filter system and filter element technology, which is applied in the field of filter systems with outlet functions, can solve the problems of increasing cost and workload, and achieve the effect of reducing drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

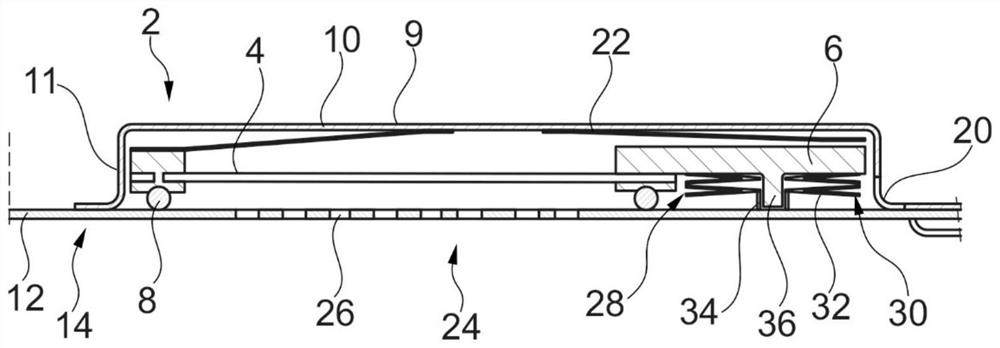

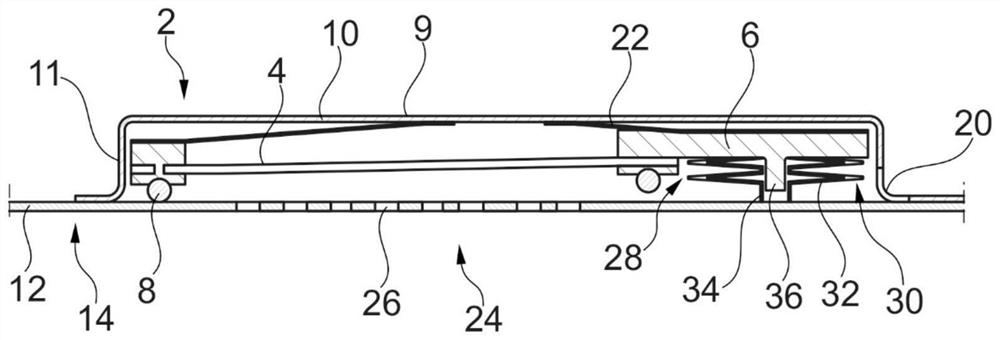

[0059] The following will refer to figure 1 and figure 2 A first embodiment of a filter system 2 according to the invention is described.

[0060] figure 1 The filter system 2 is shown in a cold state. The filter system 2 comprises a disc-shaped filter element 4 which is firmly framed or pressed in an annular holder 6 and a sealing ring 8 . A sealing ring 8 is arranged in the outer region of the holder 6 , which corresponds to the outer diameter of the filter element 4 . In other words, the diameter of the sealing ring 8 approximately corresponds to the diameter of the filter element 4 . The holder 6 is accommodated together with the filter element 4 and the sealing ring 8 in the pot lid 10 . A surrounding peripheral wall 11 extends from the circular cover part 9 of the cover 10 . Cap 10 may be attached to sterile container base 12 of sterile container 14 (eg, by clamping, screwing, or turning). For this purpose, a groove 16 is provided in the sterile container base 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com